Your Guide to Safe Display Materials 2025

You need display cases that are durable, safe, and attractive. Modern plastics like polycarbonate and acrylic offer excellent solutions. They resist breakage and improve overall safety. These safe display materials boost product freshness and durability. Your food packaging goals should enhance product freshness, food safety, food freshness, and food safety.

Key Benefits of Modern Packaging: Your

packagingdeliversfoodsafetyandfoodfreshness. Yourpackagingprovidesfoodsafetyandfoodfreshness. Thispackagingenablesshelf life extension,shelf life extension,shelf life extension,shelf life extension,shelf life extension,shelf life extension,shelf life extension,shelf life extension,shelf life extension, andshelf life extension. Thisextensionextensionextensionextensionextensionextensionextensionextensionextensionextensionis vital for yourfood. Thepackagingpackagingpackagingpackagingpackagingpackagingsupportsproduct freshness.

TOP BREAKAGE-RESISTANT MATERIALS

Choosing the right material is your first step toward eliminating breakage. You need displays that stand up to daily use. Modern plastics offer incredible strength compared to traditional glass. They provide excellent safety and durability. Let's compare the top options for your business. These innovative materials support food preservation. Your packaging choices also influence this preservation. Good packaging and display choices work together for food safety. This combination is key for shelf life extension. An active approach to material selection prevents physical damage.

POLYCARBONATE FOR ULTIMATE DURABILITY

You should choose polycarbonate for maximum impact resistance. This material is virtually unbreakable. It is a top choice for high-traffic areas where safety is a primary concern. Polycarbonate protects your food products from accidental damage. This protection is an active part of your food safety strategy. Its strength ensures long-term durability.

Polycarbonate is significantly stronger than other options. You can see the difference in impact strength clearly.

| Material | Impact Strength (ft·lb/in²) |

|---|---|

| Polycarbonate | 10 |

| Acrylic | 1 |

Polycarbonate has 250 times the impact resistance of standard glass. This makes it an ideal material for protective shields, bulk bin lids, and display cases in busy aisles. For food contact, you must use specific food-safe grades.

Note on Food Safety: Look for polycarbonate resins certified under NSF/ANSI 51. These ensure the material is safe for direct food contact. Examples include CALIBRE™ 200-3 and CALIBRE™ 201 series resins. Using certified materials is a critical part of your food safety plan. This innovative step aids in food preservation.

ACRYLIC FOR SUPERIOR CLARITY

You can use acrylic when visual presentation is your top priority. It offers exceptional clarity, often better than glass. This makes your food products look vibrant and appealing. Acrylic is also 17 times more resistant to impact than glass. It provides a great balance of aesthetics and strength. This innovative material is perfect for pastry cases, bakery displays, and sneeze guards.

However, you must handle acrylic carefully during fabrication to prevent stress. Stress can cause cracks and reduce the material's lifespan.

- Fabrication Tip: Use tools designed for plastics. These tools scrape the material instead of digging into it. This minimizes stress fractures.

- Installation Tip: Avoid overtightening screws. You should finger-tighten fasteners and then back them off a quarter turn. This allows the material to expand and contract, preventing cracks.

- Material Choice: You might prefer cast acrylic over extruded acrylic. Cast acrylic has greater resistance to stress-induced cracking.

Proper handling ensures your acrylic displays maintain their beauty and safety. This care contributes to the overall preservation of your food presentation. Your packaging also plays a role in this preservation. The right packaging solutions enhance the freshness you display.

COPOLYESTER FOR CHEMICAL RESISTANCE

You need copolyester for displays that require frequent and harsh cleaning. This innovative plastic offers superior resistance to cleaning chemicals. It will not crack or haze like other plastics might. This makes it an excellent choice for deli cases, salad bars, and other areas needing rigorous sanitation. Copolyester provides a durable and safe display materials option.

Copolyester combines good impact strength with excellent chemical compatibility. This ensures your displays remain clear and strong, even with constant cleaning. This active preservation of the display's integrity is vital for food safety. Your packaging strategy should also consider preservation. Innovative packaging like modified atmosphere packaging helps with shelf life extension. This extension is a goal for all food businesses. The right packaging offers an active defense for food freshness. Modified atmosphere packaging is a great tool for shelf life extension. This extension helps your business. Modified atmosphere packaging is an innovative method for shelf life extension. This extension protects your food. Modified atmosphere packaging is a key part of shelf life extension. This extension is important for food safety. Modified atmosphere packaging is a reliable way to get shelf life extension. This extension is a form of preservation. Modified atmosphere packaging is a smart choice for shelf life extension. This extension is a modern food preservation technique. Modified atmosphere packaging is an active method for shelf life extension. This extension is a form of food preservation. Modified atmosphere packaging is a great way to achieve shelf life extension. This extension is a form of active preservation.

KEY FACTORS FOR SAFE DISPLAY MATERIALS

Selecting the right material involves more than just strength. You must consider how it impacts food safety, where you will place it, and how you will maintain it. These factors work together to create a safe, effective, and attractive display environment. A thoughtful approach ensures the long-term success of your safe display materials.

FOOD SAFETY & COMPLIANCE

You must prioritize food safety above all else. Materials that touch food must meet strict government standards. This is a non-negotiable part of your food safety management plan. The U.S. Food and Drug Administration (FDA) sets these rules under Title 21 of the Code of Federal Regulations (21 CFR). Your packaging and displays must comply for legal and safety reasons.

The FDA maintains a list of approved substances for food contact. These regulations ensure that no harmful chemicals migrate from the material into the food. Key parts of 21 CFR include:

- Part 174: Covers substances used in products that contact

food. - Part 177: Details specific rules for polymers like polyurethane and nylon resins.

- Part 178: Regulates sanitizers and production aids used on

foodcontact surfaces. - Part 186: Lists substances generally recognized as safe (GRAS) for indirect

foodcontact. - Part 189: Prohibits certain substances, like lead solders, from use in any

foodcontact materials.

Beyond FDA rules, you should look for NSF certification. This certification provides an extra layer of assurance for your food safety program. It confirms the material is safe and the product is well-made. This is crucial for food freshness and safety.

NSF food equipment standards include requirements for material

safety, to ensure the product will not leach harmful chemicals intofood; design and construction, to ensure the product is cleanable and is not likely to harbor bacteria; and product performance. NSF certification to these standards also includes audits of the production facility to ensure the product is made using good manufacturing practices.

DURABILITY AND LOCATION

You need to match the material's durability to its location in your store. A display in a busy aisle faces different risks than one behind a counter. Choosing the right material for each zone prevents physical damage and reduces replacement costs. The thickness of a material also plays a big role. A 6mm acrylic sheet, for example, can resist impacts from much greater heights than a 3mm sheet. Thicker materials offer a longer service life, protecting your investment and ensuring continuous safety. This extension of the display's life is a smart business choice. Your packaging choices also contribute to an extension of product life, and together, these strategies support overall freshness. This extension is a key goal. A focus on shelf life extension is vital. This extension protects your food. This extension helps your business. This extension is a form of preservation. This extension is a modern technique. This extension is an active method. This extension is a great way to achieve shelf life extension. This extension is a form of active preservation.

Use this chart to guide your decisions:

| Store Zone | Recommended Materials | Key Characteristics |

|---|---|---|

| High-Traffic (Checkout, Aisles, Entrances) | Polycarbonate, Copolyester, Tempered Glass | Maximum impact resistance is needed to prevent accidental breakage from carts and customers. |

| Low-Traffic (Behind Counter, Wall Cases) | Acrylic, Wood Accents, Standard Glass | Aesthetics and clarity are priorities. These areas have a lower risk of impact damage. |

CLEANING AND MAINTENANCE

Proper cleaning is essential for both appearance and food safety. Different materials require different cleaning methods. Using the wrong chemical can ruin a display's clarity or strength. Glass is non-porous, making it very easy to disinfect without degradation. Some plastics are more porous and can trap microorganisms, making diligent cleaning even more important for food freshness. Your packaging also helps maintain freshness. This packaging is a barrier. This packaging supports shelf life extension. This packaging is vital. This packaging is key. This packaging is a great tool. This packaging is an innovative method. This packaging is a reliable way. This packaging is a smart choice. This packaging is an active method.

Follow these tips for common materials:

- Polycarbonate: You should use a gentle dish soap and warm water. For disinfection, a mix of isopropyl alcohol and distilled water (50/50 ratio) works well. Avoid harsh chemicals.

- Acrylic: Scratches can happen, but you can often repair them. To restore clarity, you can follow a simple process.

- Choose a high-quality acrylic polishing compound.

- Apply the compound with a soft cloth in gentle, circular motions.

- For deeper scratches, wet sand the area with fine-grit sandpaper before you polish.

AESTHETICS AND PRESENTATION

The look of your displays directly influences how customers perceive your products. Clear, clean safe display materials make your food look fresh and appealing. The right aesthetics can enhance your brand and encourage sales. You can create a unique and inviting atmosphere by combining different materials.

Think beyond the primary plastic or glass case. You can use complementary materials to frame your displays and create visual interest. For example, you might use sleek metal fixtures to give your bakery a modern, clean look. Alternatively, you could incorporate rich wood elements around your displays to create a warm, artisanal feel. This thoughtful design reinforces the quality and freshness of your products. Your packaging design should also align with this aesthetic to present a cohesive brand experience that promotes shelf life extension and safety.

ADVANCED CONSIDERATIONS FOR 2025

You can elevate your displays by looking at future-focused solutions. Advanced coatings, innovative packaging, and a focus on sustainability will define the next generation of food safety and presentation. These active steps improve product freshness and quality retention.

SPECIALTY COATINGS FOR PERFORMANCE

You should consider specialty coatings to boost your display performance. Anti-fog coatings are an excellent innovative choice for refrigerated cases. They offer many benefits for your food and business.

- They provide a clear view of products, which can increase sales.

- They

reduce food wasteby minimizing door openings. - They improve hygiene by preventing water puddles.

- They enhance the look of your displays.

These innovative coatings are baked onto the glass surface. This process ensures their performance lasts for the lifetime of the glass. This long-term extension of clarity is a smart investment for maintaining product freshness and appeal.

MAINTAINING PRODUCT FRESHNESS

Your display material choice directly impacts product freshness. Polycarbonate is an innovative material with high heat resistance. It offers better insulation than glass, helping you maintain stable food temperatures. This active preservation is key for quality retention.

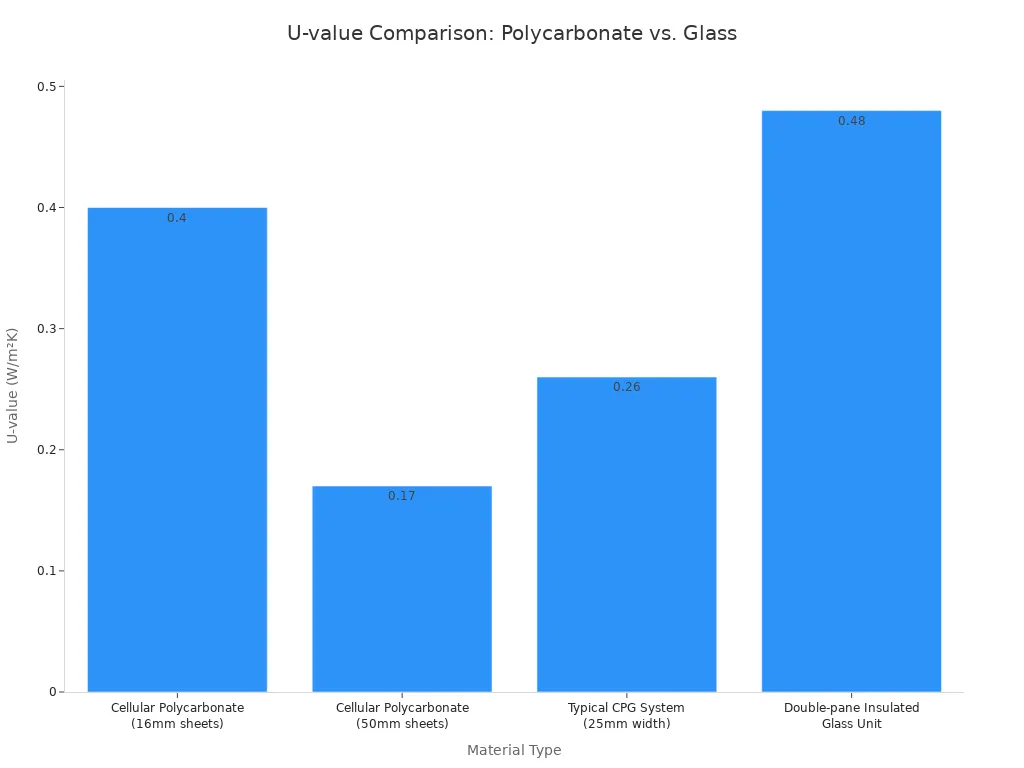

A material's U-value measures its insulating ability. A lower U-value means better insulation. Better insulation helps maintain

foodfreshnessand supportsshelf life extension. Thisextensionis a form ofactivepreservation.

Using materials with better thermal performance is an active step toward shelf life extension. This extension of freshness is a core goal. This active preservation is an innovative approach.

PACKAGING FOR SHELF LIFE EXTENSION

Your packaging is a critical tool for shelf life extension. Advanced packaging technologies offer an active protective barrier for your food. Active packaging technologies include oxygen scavengers that maintain freshness. Intelligent packaging systems use QR codes to provide customers with food information. These innovative packaging solutions are vital for shelf life extension. Modified atmosphere packaging is another active method for shelf life extension. This extension is a form of preservation. Modified atmosphere packaging is an innovative way to achieve shelf life extension. This extension is a modern preservation technique. Modified atmosphere packaging is an active method for shelf life extension. This extension is a form of active preservation. Modified atmosphere packaging is a great way to achieve shelf life extension. This extension is a form of active preservation. Modified atmosphere packaging is a smart choice for shelf life extension. This extension is a form of active preservation. Modified atmosphere packaging is a reliable way to get shelf life extension. This extension is a form of preservation. Modified atmosphere packaging is a key part of shelf life extension. This extension is important for food safety. Modified atmosphere packaging is an innovative method for shelf life extension. This extension protects your food. Modified atmosphere packaging helps your business. These innovative packaging processes ensure quality retention.

ECO-FRIENDLY & SUSTAINABLE OPTIONS

You must consider the environment in your material choices. Sustainability is increasingly important to consumers. Acrylic is a recyclable thermoplastic, but its production has a carbon footprint. Polycarbonate recycling is more complex due to its chemical makeup. Choosing sustainable packaging helps your brand and the environment.

New bio-based polymers like PLA are emerging as sustainable packaging alternatives. These materials have limitations. PLA has lower heat resistance than traditional plastics. However, innovative research is improving their strength. Embracing sustainability can reduce food waste and improve your brand image. Your packaging solutions and display choices show your commitment to the environment. This focus on sustainability is an active part of modern business. Sustainability is good for the environment. Sustainability is a key goal. Advanced packaging technologies and innovative packaging processes are driving food waste reduction. These packaging solutions are good for the environment. These active packaging technologies are innovative. These advanced packaging technologies are part of sustainable packaging. These packaging solutions are innovative. These packaging solutions are active. These packaging solutions are advanced packaging technologies. These packaging solutions are active. These packaging solutions are active. These packaging solutions are active. These packaging solutions are active. These packaging solutions are active.

You should choose modern plastics and tempered glass for your displays. This choice eliminates breakage and enhances safety. Your investment in the right safe display materials is a strategic decision. It reduces costs and improves product freshness.

Your packaging ensures food safety and food freshness. Your packaging provides food safety and food freshness. This packaging enables shelf life extension, shelf life extension, shelf life extension, shelf life extension, and shelf life extension. This extension extension extension extension extension is vital for your food. Your packaging packaging packaging packaging packaging supports product freshness. Your sustainability goals support food safety. This sustainability focus aids food freshness. Your sustainability efforts help food safety. This sustainability commitment boosts food freshness. Your sustainability plan ensures food safety.

Review your display safety today. Protect your staff, customers, and bottom line.

FAQ

What is the best material for a high-traffic area?

You should use polycarbonate for busy areas. Its high impact resistance protects your food from accidents. This choice complements your food packaging strategy. Good packaging also protects the food. This material ensures the safety of your food display.

How do I ensure my displays are food-safe?

You must choose materials with FDA or NSF certification for food contact. This rule applies to your displays and your packaging. Proper material selection is vital for food safety. This protects the food you sell and ensures compliance.

How can displays improve shelf life extension?

Insulating materials like polycarbonate help maintain stable food temperatures. This stability is key for shelf life extension. Your packaging also provides shelf life extension. This extension is a primary goal for all food. This extension protects your food. This extension is vital. This extension is important. This extension is key. This extension is a goal. This extension is a benefit. This extension is a plus. This extension is an advantage.

Can I use wood in my food displays?

You can use wood for aesthetic accents away from direct food contact. Your primary food display should use non-porous materials. Your packaging provides the main barrier for the food. This separation keeps your food safe and fresh. This packaging supports shelf life extension. The packaging enables shelf life extension. The packaging helps shelf life extension. The packaging allows shelf life extension. The packaging creates shelf life extension.