UV Resistance Basics for Retailers

You have two primary solutions to prevent display fixtures from yellowing. First, specify materials with built-in uv protection. Second, apply protective films to your current glass and display units for immediate protection.

Understanding these uv resistance basics is key. These practical solutions offer long-term preservation for your store's aesthetic. This guide focuses on the preservation and protection of every display.

UV RESISTANCE BASICS: THE CAUSE

Understanding why your fixtures degrade is the first step in prevention. The enemy is a scientific process called photo-oxidation. Ultraviolet (UV) light, specifically UV-A and UV-B rays in the 290-400 nm range, carries enough energy to break down the molecular bonds in polymers. This process causes the yellowing and brittleness you see. The primary sources of this damaging light in your store are direct sunlight through window glass and certain types of artificial light, like older fluorescent or metal halide bulbs. You must also watch for heat, as high temperatures work with UV light to speed up discoloration. These are the core uv resistance basics.

VULNERABLE DISPLAY MATERIALS

You need to know which materials are at risk. Many common plastics used for a retail display will degrade without special protection. Standard acrylic, polycarbonate, and ABS are highly susceptible. You will watch these materials yellow and lose their strength over time. A beautiful watch display can quickly look dated. Wood fixtures also suffer, especially those with certain finishes. For example, some varnishes will yellow when exposed to UV light. Even the glass of a display case offers little protection on its own. You must keep the display glass clean to monitor the condition of the watch inside.

Retailer Alert: A bright, sunlit spot may seem perfect for a premium watch display. However, the combination of direct UV light and heat from the sun creates a worst-case scenario. This will rapidly damage both the display and the merchandise, like a leather watch strap behind the glass. You need to watch the condition of every glass surface.

NATURALLY RESISTANT MATERIALS

Fortunately, you can choose materials with inherent protection. This is a key part of uv resistance basics. Certain advanced polymers offer excellent durability.

- PTFE (Teflon): This material has extremely strong carbon-fluorine bonds. These bonds resist UV light, preventing degradation.

- UV-Grade Polycarbonate: While standard polycarbonate is vulnerable, you can specify grades with built-in UV stabilizers. Its molecular structure is designed to absorb UV light before it can cause damage.

Other excellent choices include stone, metal, and high-quality laminated glass. When you plan a new display, specifying these materials from the start is the most effective strategy. Understanding these material uv resistance basics helps you protect your investment in every watch display and glass fixture.

PROACTIVE MATERIAL SELECTION

Making smart material choices from the beginning is your most powerful strategy. Proactive selection provides built-in defense against UV damage. This approach ensures the long-term preservation of your store's luxury aesthetic and is one of the best solutions you can implement.

SPECIFYING UV-GRADE ACRYLIC

When you commission a new fixture, you should specify UV-grade acrylic. Standard acrylic will yellow, but UV-stabilized versions resist color degradation for years. This material is a cornerstone of modern retail display design.

- Lifespan and Value: You can expect a high-quality UV-printed acrylic display to last 5 to 10 years. While these materials have a higher initial cost, their extended lifespan offers greater long-term value. You will spend less on repairs and replacements over time. This is a key part of effective preservation.

- Industry Standards: Look for products that meet rigorous standards. For example, the UV STANDARD 801 certification tests materials under harsh, realistic conditions. It ensures products like shading textiles and films provide reliable uv protection. This gives you confidence in the material's performance.

For a truly secure display, the assembly process matters. Using a high-quality uv glue ensures the bonds between acrylic sheets are as strong and clear as the material itself. A specialized uv glue cures quickly and creates a seamless look for any glass or acrylic display. When enclosing valuable items, you should also consider using acid-free materials for all internal components. For prints or documents, an acid-free archival backing is essential for complete preservation.

Retailer Tip: When discussing a new glass display case with your fabricator, ask about the specific grade of acrylic and the type of uv glue they use. A premium uv glue will not yellow, maintaining the clarity of the joints and the overall quality of the display.

CHOOSING UV-STABLE COATINGS

You can also protect existing fixtures made of wood, metal, or even standard glass. Applying a professional UV-stable coating offers excellent protection. These coatings create a durable barrier that guards against fading and yellowing.

There are several advanced coating solutions available.

- Water-Based Urethane Topcoats: These coatings are eco-friendly and durable. They offer excellent resistance to scratches and UV rays, making them ideal for high-traffic retail stores.

- Polyaspartic Topcoats: This is a type of urethane known for its rapid curing time and extreme durability. It provides a high-gloss finish and superior UV stability for any display.

The application of these coatings is a precise, professional process. Technicians will sand the surface, apply fillers, and then add multiple base and top coats. Each layer is cured in seconds using UV lamps. This rapid process minimizes downtime for your store. The right adhesive and coating combination provides robust protection. You can apply these coatings to wood, metal, and even glass surfaces. The final layer on the glass will be crystal clear. Using a quality uv glue for any repairs before coating is also one of the better solutions. This uv glue will secure the piece for a lasting finish. The right adhesive is critical. For a glass display, the clarity of the uv glue is paramount. This ensures the glass remains perfectly transparent. The final glass surface will look pristine.

FIXTURE PROTECTION FOR EXISTING STORES

If you are not planning a full redesign, you can still implement powerful protective solutions. Retrofitting your current store with the right technology provides immediate and effective defense against UV damage. These strategies focus on controlling the sources of UV light: your windows and your lighting fixtures.

UV-BLOCKING WINDOW FILMS

Your storefront glass is the largest entry point for damaging UV radiation. Applying a professional-grade window film is one of the most impactful actions you can take. These advanced films are a critical component of uv protection. High-performance ceramic films are virtually clear. They block up to 99% of both UV-A and UV-B rays while allowing beautiful, natural light into your space. This level of protection is essential for long-term preservation.

These films do more than just protect your fixtures. They are crucial for safeguarding your merchandise. A luxury leather watch strap or a vibrant gemstone on display will resist fading. This protection extends the life of your inventory and maintains its value. Major brands have successfully used this strategy.

- Exxon Tiger Market Stores specified window coatings with UV inhibitors to control solar heat and provide

protection. - Jollibee Fast Food Restaurants installed similar coatings in their dining areas, demonstrating the effectiveness of retrofitting.

Retailer ROI: You will likely see a return on your investment in window film within 12 to 24 months. The cost of installation is often less than the cost of replacing a single faded furniture set. When you add energy savings and extended inventory life, the payback period for these

solutionsis even shorter.

Choosing the right product and installer is key. You should seek professional help for installation. Leading brands offer excellent solutions:

- Llumar® Ceramic Films provide 99% UV blockage with outstanding clarity.

- Vista™ by 3M™ films combine 99% UV

protectionwith energy efficiency. - Madico® Solar Control Films offer a wide range of options for heat and UV control.

A common concern is how films affect the appearance of merchandise. Modern films have a high Color Rendering Index (CRI), which measures how accurately colors appear.

| CRI Value Range | Color Rendering Quality |

|---|---|

| 90-100 | Excellent |

| 60-85 | Fair (colors may appear distorted) |

| 55 and below | Poor |

High-quality films from top brands typically have a CRI above 90. This ensures the colors of your products, from a vibrant watch face to a colorful handbag, remain true. Before applying film, inspect your glass for any chips. A tiny repair with a clear uv glue can prevent a crack from spreading. The adhesive on the film itself is engineered for a perfect, bubble-free bond to the glass. These films are one of the best protective accessories for any retail display. This also protects items in storage near windows. The preservation of your watch collection depends on controlling the environment. A clear uv glue can also be used to seamlessly repair a chipped glass shelf inside a display case before it gets worse. A strong adhesive is vital for any long-term repair. The glass of a watch display must be flawless.

UV-SAFE LIGHTING UPGRADES

Your store's artificial light is another source of potential damage. Older systems like metal halide and fluorescent bulbs emit significant UV radiation. Upgrading your lighting is a two-fold win. You eliminate a source of damage and dramatically reduce operating costs.

The best choice is to upgrade to modern LED lighting. LEDs emit negligible UV light and offer huge energy savings. You can expect to reduce lighting-related energy consumption by 60% to 80%. Maintenance costs can also drop by over 90% due to the long lifespan of LED fixtures.

Cost Savings: Metal Halide vs. LED (Example for 100 Fixtures)

| Metric | Metal Halide (455W) | LED (100W) | Annual Savings |

|---|---|---|---|

| Annual Cost (@ $0.12/kWh) | $23,914 | $5,256 | $18,658 |

If an immediate full upgrade is not possible, you can retrofit your existing lights. You can apply special UV-blocking filters over your current bulbs and fixtures. These protective accessories are available in various formats.

| Product Type | Common Dimensions |

|---|---|

| UV Filter Sheets | 20" x 24" (50.8 cm x 61 cm) |

| UV Filter Rolls | 48" x 25' (122 cm x 7.6 m) |

These filters are transparent sheets that absorb UV rays below 390 nanometers. You can have them cut to fit the glass lens of a spotlight. A tiny dab of high-temperature uv glue can secure the filter in place. This simple modification protects your watch display from focused light damage. For complex systems, you should get professional help. This ensures the preservation of every watch on display. The glass of the watch itself offers some protection, but the display glass and lighting are your responsibility. Even items in backroom storage benefit from UV-safe light. You can even use a specialized uv glue to create custom holders for these protective accessories on unique fixtures. The right uv glue is a versatile tool. The glass of a watch case needs to be perfect.

LONG-TERM PRESERVATION AND PROTECTION

Your commitment to UV protection does not end with material selection or retrofitting. You must implement a long-term strategy for preservation and protection. This ensures your fixtures, from a primary watch display to backroom storage units, maintain their premium appearance. Effective environmental control and monitoring are key to this process.

REGULAR INSPECTION

You should establish a routine inspection schedule to catch problems early. This proactive approach is vital for the preservation of every watch display and storage area.

- Weekly Checks: Your staff should perform quick weekly inspections. They can check for loose screws, minor scratches, or damage on high-traffic storage and display units. This is especially important for a delicate watch display.

- Quarterly Deep Dives: You should conduct a more thorough inspection every quarter. Look closely at joints, surface integrity, and signs of discoloration on every watch fixture. Documenting your findings helps track the effectiveness of your environmental control and monitoring efforts. For complex issues, you should seek professional help.

Retailer Alert: Pay special attention to fixtures near windows or under direct lighting. These areas suffer the most. A small chip in a glass watch case can quickly become a large crack, compromising both safety and the protection of the watch inside. Consistent inspection of storage and display fixtures is one of your best solutions.

PROPER CLEANING AND CARE

Proper cleaning is essential for preservation. You must use the right methods for each material to avoid causing damage. This applies to every watch display and storage unit.

| Fixture Material | Recommended Cleaning Method |

|---|---|

| Wood | Use a soft, damp cloth. Avoid harsh chemicals. |

| Metal | Use a non-abrasive cleaner to remove smudges. |

| Glass/Acrylic | Use a gentle glass cleaner and a lint-free cloth. |

When cleaning surfaces with UV films or coatings, you must be careful. Avoid abrasive cleaners, stiff brushes, and harsh chemicals. These can scratch the surface and degrade the UV protection. This careful approach is crucial for the long-term preservation of your watch collection and storage areas.

PLANNING FOR FUTURE REFRESHES

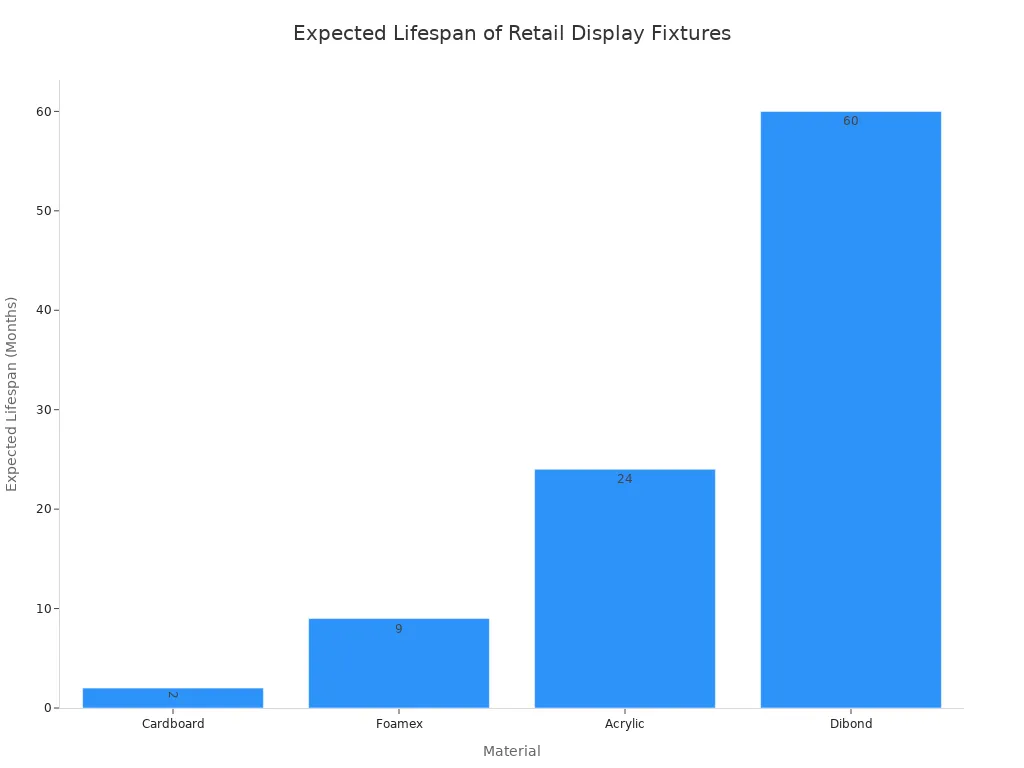

Even with perfect care, all fixtures have a lifespan. You need to plan for future refreshes to keep your store looking its best. Understanding material longevity helps you budget and schedule these updates. Metal and Dibond offer the best long-term solutions, while acrylic provides a mid-range option for a watch display. This planning is the final step in your environmental control and monitoring strategy.

When the time comes to replace a fixture, you can consult with experts for the best materials and designs. Seeking professional help ensures your new storage and display units offer maximum protection for each watch.

You can master uv resistance basics with three key actions.

- Specify UV-grade materials during design.

- Retrofit stores with films for immediate protection.

- Follow a strict maintenance plan.

Your commitment to uv protection is a direct investment. You ensure the long-term preservation of your brand's luxury image. This effort also guarantees the preservation of your valuable merchandise.

FAQ

Can I use DIY solutions for UV protection?

You can try some diy solutions. A diy approach might involve placing a watch away from a window. However, professional films offer better protection for your glass display and storage units. A diy fix is not a long-term solution for a valuable watch. Avoid diy watch glass repair.

Is the sapphire glass on a watch enough protection?

A sapphire watch crystal offers excellent scratch resistance. It does not protect the entire watch display. The case, strap, and surrounding storage fixtures still need protection. You should not rely only on the sapphire glass. A complex watch glass repair on a sapphire crystal is difficult.

How do I protect a watch in long-term storage?

You must control the storage environment. Use UV-safe lighting in your storage rooms. Keep each watch in a protective box. This prevents dust and light exposure. Your storage plan should be as robust as your display plan. A diy storage box is not recommended for a luxury watch.

What is the best diy method for glass storage?

A simple diy method is to cover glass storage units with opaque cloths. This diy step blocks light. It is a temporary fix for a watch collection. For permanent protection of glass storage, you need professional films. A diy solution cannot replace professional watch glass repair or protection.