UV Resistance Basics for Clear Fixtures

You can stop your clear fixtures from yellowing. The most effective method is a two-part strategy.

- Select UV-resistant materials like UV-grade acrylic from the start.

- Implement simple protections like UV-filtering window films and LED lighting.

Understanding these UV resistance basics helps you protect your investment. Your actions will keep your store looking clean and professional, helping you attract more customers. 🛍️

Understanding UV Resistance Basics

Understanding UV resistance basics starts with knowing your opponent: ultraviolet (UV) radiation. Sunlight entering your store contains these invisible rays, and they are the primary cause of material damage. Limiting direct sunlight on your fixtures is a critical first step in protecting them.

The Role of UV Radiation

UV radiation attacks clear materials through a process called photodegradation. Think of it as a slow, constant sunburn for your fixtures. The energy from UV rays breaks the chemical bonds inside the plastic. Oxygen in the air often speeds up this damage, a process known as photooxidation.

This breakdown causes two main problems:

- Yellowing: The material loses its clarity and turns a dingy yellow or brown.

- Weakening: The plastic becomes brittle and can crack or break more easily.

Did You Know? This damage often starts on the surface. UV radiation first affects a very thin top layer. Over time, oxygen helps the degradation move deeper, eventually damaging the entire fixture.

Learning these UV resistance basics helps you see why material choice is so important.

Susceptible Fixture Materials

Not all clear plastics handle sunlight equally. Many standard, off-the-shelf materials are highly susceptible to UV damage. The two most common culprits you will encounter are:

- Standard Acrylic

- Standard Polycarbonate

Standard polycarbonate is especially vulnerable. Its chemical structure contains specific groups that act as starting points for UV degradation. When UV light hits these spots, it triggers reactions that break down the polymer chains. This chemical change is what directly causes the material to lose its strength and turn yellow. Some manufacturers even add a thin protective layer of acrylic onto polycarbonate sheets to shield them from this effect.

Selecting UV-Resistant Materials

Choosing the right material from the beginning is one of the most important UV resistance basics. Your choice directly impacts how long your fixtures will look new. You have two excellent options, each with unique strengths for different retail needs.

UV-Grade Acrylic for Optical Clarity

You should choose UV-grade acrylic when your top priority is a crystal-clear appearance. This material, also known as polymethyl methacrylate (PMMA), has excellent natural resistance to ultraviolet radiation. High-quality UV-resistant acrylic can last 10 to 15 years before showing any signs of yellowing. Standard acrylic, in contrast, often starts to yellow within 5 to 7 years.

UV-filtering acrylic offers the best protection. Some brands, like Perspex®, guarantee their clear sheets will not yellow and will keep at least 85% of their light transmission for 30 years. Products from manufacturers like Acme Plastics and Piedmont Plastics are specifically made to fight UV damage. For example, frame-grade acrylic sheets can block up to 98% of UV rays, making them a popular choice for high-end displays.

Pro Tip: Look for Certifications 🏆 Reputable acrylic materials often meet strict industry standards. These certifications confirm their quality and safety for use in your store. Look for materials that comply with:

- Photographic Activity Test (PAT) ISO 18916: Ensures the material will not harm photos or artwork.

- USP Class VI / ISO 10993: Certifies the material is medical-grade and non-toxic.

- ISO 18902: A standard for photo-safe materials, ideal for archival-quality displays.

Coated Polycarbonate for Toughness

You should choose coated polycarbonate when your top priority is preventing breakage. This material is incredibly strong and virtually unbreakable. It has about 250 times the impact resistance of glass, while acrylic has only 17 times. This makes it perfect for fixtures in high-traffic areas, on busy sales floors, or where there is a risk of impact.

Standard polycarbonate yellows quickly under sunlight. To solve this, manufacturers add a special UV-resistant coating to one or both sides of the sheet. This protective layer allows the material to last 10 to 15 years without degrading. Some polycarbonates also have an abrasion-resistant coating, like a Diamond-like carbon (DLC) layer, which protects them from scratches.

A Note on Cleaning Always clean coated polycarbonate with a mild soap and water solution. Avoid harsh chemical cleaners or solvents, as they can damage the protective UV coating. Check the manufacturer's guidelines for the best results.

Material Comparison Chart

Making the right choice depends on your specific needs for budget, appearance, and durability. This chart breaks down the key differences between your two best options.

| Feature | UV-Grade Acrylic | Coated Polycarbonate |

|---|---|---|

| Impact Resistance | Good (17x stronger than glass) | Exceptional (250x stronger than glass) |

| Optical Clarity | Excellent (92% light transmission) | Very Good (88% light transmission) |

| UV Resistance | Naturally excellent | Excellent with a protective coating |

| Scratch Resistance | More resistant to scratches | Scratches easily without a hard coat |

| Cost (per sq. foot) | $5 - $15 | $10 - $30 |

Ultimately, your decision is a trade-off. UV-grade acrylic gives you superior optical clarity at a lower cost. Coated polycarbonate provides unmatched toughness and safety, making it a smart investment for demanding environments.

Practical Steps for Fixture Protection

Selecting the right materials is a great start. You can take further action to protect your fixtures from UV damage. These practical steps create a safer environment for your displays and extend their lifespan. Following these UV resistance basics will safeguard your investment.

Specify Materials with Suppliers

You must be clear about your needs when ordering fixtures. Do not assume a supplier will provide UV-resistant materials automatically. You should actively specify your requirements to ensure you get the quality you pay for.

Clear communication prevents costly mistakes. You can ask suppliers to provide detailed material specifications to a testing laboratory. This process confirms the testing scope, standards, and methods for UV protection. To verify a material's quality, you should request two key documents:

- Test Report: This document shows the UV protection factors from tests performed on the material.

- Declaration of Conformity: This form shows the supplier has submitted the material to a test institute and follows industry standards.

Real-World Success 📈 Holding suppliers accountable works. A home goods retailer created new packaging standards for its vendors, which reduced product damage. Similarly, a global apparel retailer enforced a textile certification strategy to improve quality. You can apply the same principle to your fixture materials.

Install UV-Filtering Window Films

Your store's windows are a major source of UV radiation. You can solve this problem by installing UV-filtering window films. High-quality window films are a powerful tool. They can block up to 99% of harmful UV rays from entering your store. This simple upgrade acts like sunscreen for your entire retail space, protecting not only your fixtures but also your merchandise.

These films offer an extra benefit: energy savings. UV and infrared (IR) radiation from the sun also carry heat. Blocking these rays helps keep your store cooler. This reduces the strain on your air conditioning system. You could see your cooling costs drop by up to 30%.

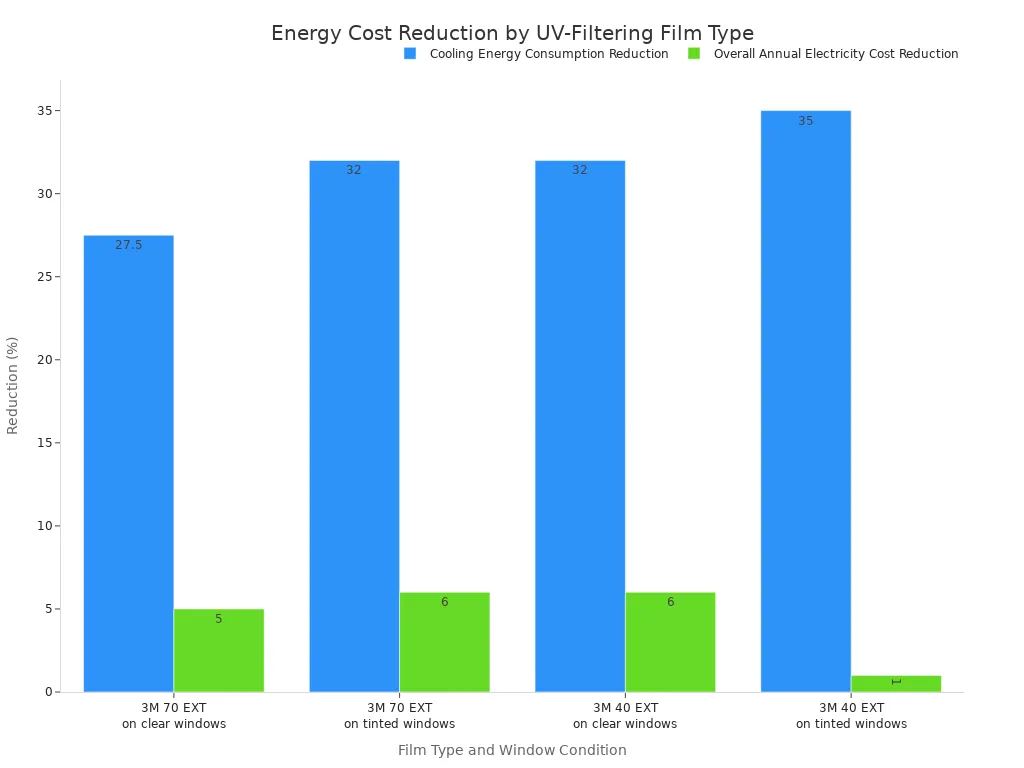

The amount you save depends on the film type and your existing windows. The chart below shows how different films can reduce energy use.

| Film Type & Window Condition | Cooling Energy Consumption Reduction | Overall Annual Electricity Cost Reduction |

|---|---|---|

| 3M 70 EXT on clear windows | 27% - 28% | 5% |

| 3M 70 EXT on tinted windows | 32% | 6% |

| 3M 40 EXT on clear windows | 32% | 6% |

| 3M 40 EXT on tinted windows | 35% | 1% |

This data shows how different films perform under various conditions.

Optimize In-Store Lighting

The lights inside your store can also damage clear fixtures. Some types of lighting emit UV radiation. Choosing the right bulbs is a key part of protecting your displays.

Fluorescent bulbs create light by generating UV radiation inside the tube. A phosphor coating converts most of this UV light into visible light. However, a small amount of UV radiation can still escape. This constant, low-level exposure will cause materials to yellow and weaken over time.

LED lights are the safest choice for your fixtures. They produce light through a different process that generates virtually no UV radiation. Switching to LED lighting eliminates a hidden source of damage. This change helps preserve the clarity and strength of your acrylic and polycarbonate displays.

| Lighting Type | UV Output |

|---|---|

| LED | None |

| Fluorescent | Emits a small amount of UV radiation that can cause fading and material damage. |

Making the switch to LED is a smart move. It protects your fixtures, saves energy, and keeps your store looking bright and professional.

You can keep your clear fixtures looking new by following a few key steps. These simple actions protect your financial investment by reducing the need for costly replacements. A bright, professional store creates a positive impression that encourages customers to make a purchase. 💡

Remember these three critical actions:

- Always choose UV-resistant materials like UV-grade acrylic when buying new fixtures.

- Proactively protect your store with UV-filtering window films and modern LED lighting.

- Be specific about your material needs with suppliers to guarantee quality.

FAQ

How do I know if my supplier sold me UV-resistant material?

You should ask your supplier for specific documents to confirm quality. Requesting these two items will verify the material's UV protection:

- A Test Report from a lab.

- A Declaration of Conformity.

These documents prove the material meets industry standards for UV resistance.

Can I just put UV film on a standard acrylic fixture?

You can, but it is not the best long-term solution. The film protects the surface, but the plastic underneath will still degrade from heat and oxygen. For lasting clarity, you should always start with a fixture made from UV-grade material.

Will cleaning products damage my fixtures' UV protection?

Yes, harsh chemicals can damage your fixtures. You should always use a mild soap and water solution. This is especially important for coated polycarbonate. Aggressive cleaners can strip away the protective UV layer, causing the material to yellow and weaken faster. 🧼

Are LED lights really that much better than fluorescent lights?

Yes, LED lights are the superior choice for protecting your fixtures. They produce almost no UV radiation. Fluorescent bulbs, however, emit a small amount of UV light. This constant exposure slowly damages clear plastics over time, causing them to yellow.