Sample-to-Mass Production Workflow for Mobile in 2025

You can master mobile manufacturing with a clear workflow. The industry-standard sample-to-mass production workflow is your roadmap from concept to a market-ready product. This structured approach to manufacturing is built on four critical phases.

The Four Core Phases of Mobile Manufacturing

- Prototyping: This initial stage builds your first physical sample.

- Design Validation Testing (DVT): You confirm the design is ready for manufacturing.

- Production Validation Testing (PVT): This phase validates your manufacturing process before mass production.

- Mass Production (MP): Here, you scale up manufacturing for a successful launch, achieving full mass production.

This disciplined process is the key to successful mass production.

Optimizing the Sample-to-Mass Production Workflow

You can improve your manufacturing outcomes with a structured plan. The sample-to-mass production workflow guides your project from an idea to a successful launch. This approach helps you manage the complex manufacturing journey and avoid costly mistakes before reaching mass production.

The Four Core Phases

Your manufacturing journey has four main stages. The prototyping phase turns your concept into a physical sample. Next, Design Validation Testing (DVT) confirms your design works correctly. Production Validation Testing (PVT) then checks your manufacturing and assembly line. Finally, Mass Production (MP) scales up your operations for the market. Each phase builds on the last, ensuring a smooth transition and high quality.

Creating the Product Specification Sheet

You need a detailed product specification sheet before starting any manufacturing. This document is the blueprint for your device. It defines every technical and functional requirement. For a 2025 mobile device, your sheet should detail key components.

- Display: AMOLED screens with 120 Hz refresh rates are common.

- Processor: Chips like the Snapdragon 9 Gen 2 or Google Tensor G3 deliver top performance.

- Camera: Systems often include 50 MP main sensors with AI enhancements.

- Battery: A capacity over 5000 mAh ensures all-day use.

- Design: Modern trends focus on sustainable materials like recycled aluminum.

This sheet aligns your team and suppliers, which is critical for the entire sample-to-mass production workflow.

Common Pitfalls to Avoid

Many teams face similar challenges in mobile manufacturing. A common mistake is poor Design for Manufacturability (DFM). This makes the device difficult or expensive to build at scale. Another pitfall is not testing enough, which leads to quality problems later. Underestimating supply chain complexity can also cause major delays in your production process.

Pro Tip: A disciplined manufacturing plan is your best defense. It helps you anticipate problems, maintain quality, and prepare for successful mass production. Following a clear plan is essential for achieving mass production on time and on budget. Good manufacturing practices lead to better mass production results.

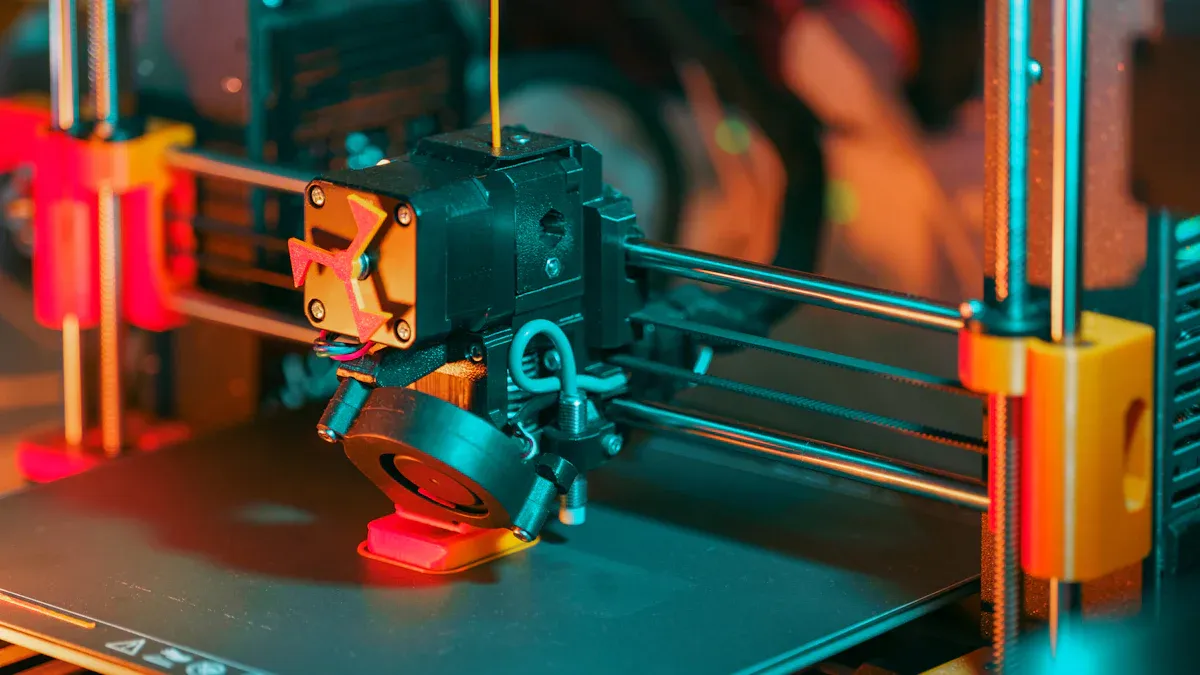

Phase 1: Prototyping

The prototyping phase is your first step in turning an idea into a physical device. This initial manufacturing process creates a tangible sample you can hold, test, and refine. It is the foundation for your entire project.

From Concept to Sample

You begin the prototype stage by building your first working model. This sample allows you to test your core concept with real users. Early feedback is crucial for success. Successful products often pivot during prototyping based on user reactions.

From Prototype to Product 💡

- Instagram started as a prototype called 'Burbn' but focused on photo-sharing after user feedback.

- Dropbox used a video prototype to demonstrate its service, which helped validate the idea before full development.

Merging Form and Function

Your prototype must balance appearance (form) with usability (function). This is where you check if the device feels good in your hand and if the buttons are easy to press. The goal is to create a design that is both beautiful and practical. This early stage of manufacturing helps you identify design flaws before they become expensive problems. The successful transition from prototype to the next phase depends on getting this balance right.

Early DFM Application

You should apply Design for Manufacturability (DFM) principles during the prototype stage. DFM means designing your product to be easy to produce. Thinking about large-scale manufacturing now will save you time and money later. A simple change in the prototype stage can make the final manufacturing process much more efficient. This proactive approach to manufacturing is essential for a smooth workflow.

Modern Prototyping Challenges

Modern mobile devices present unique prototyping challenges, especially with new form factors. For example, foldable phones require complex engineering. The transition from prototype to a finished product is more difficult with these advanced designs.

Key challenges in advanced manufacturing include:

- Hinge Engineering: Creating durable hinges that allow for thousands of folds.

- Battery Segmentation: Splitting batteries across two halves of a device.

- Waterproofing: Sealing moving parts against moisture and dust.

Solving these issues during prototyping is critical for successful manufacturing.

Phase 2: Design Validation Testing (DVT)

You have a working prototype. Now, you enter the Design Validation Testing (DVT) phase. This stage is where you rigorously test your design using production-intent parts and processes. The goal is to confirm that your design meets all specifications before you invest in expensive tooling for mass manufacturing. A successful DVT makes the transition from prototype to production much smoother.

Verifying the Design

You must verify that your design can withstand real-world conditions. This involves a series of environmental, mechanical, and electrical tests to ensure product quality. This testing and validation step is critical for identifying design weaknesses.

- High-Temperature Tests: You check if the phone operates correctly and avoids overheating in hot environments.

- Low-Temperature Tests: You assess battery life and screen responsiveness in extreme cold.

- Damp Heat Tests: You evaluate the phone's performance and corrosion resistance in humid conditions.

- Mechanical Shock Tests: You simulate drops and impacts to test the device's structural integrity and overall quality.

Supplier Vetting and Selection

During DVT, you must finalize suppliers for your critical components. The quality of these parts directly impacts your final product and manufacturing efficiency. You should vet suppliers based on their technical capabilities and quality control.

For advanced components like 5G antennas, look for suppliers with:

- Advanced Manufacturing Techniques: Expertise in Laser Direct Imaging (LDI) for precise circuitry.

- In-House Capabilities: CNC machining for complex parts, which reduces assembly defects.

- Quality Validation: Strong material traceability and reliability testing, like thermal cycling.

Core Best Practices

A core best practice in DVT is to establish and monitor Key Performance Indicators (KPIs), especially for battery life. This validation ensures your device meets user expectations. Analyzing these metrics helps you optimize software and hardware for better performance and quality. This is a key part of the transition from prototype.

| Metric | Optimal Value | Impact on Battery Life |

|---|---|---|

| CPU Usage (Idle) | Below 15% | Significant Drain |

| Battery Temperature | Below 40°C | Quicker Degradation |

| Battery Discharge | < 5% per hour | Poor User Experience |

Navigating Compliance and Certification

You should begin the certification process during DVT to avoid delays in your manufacturing timeline. For cellular devices, you need certifications like PTCRB for North America and GCF for other regions. The process ensures your device complies with network standards, which is essential for market access and product quality. This step solidifies the transition from prototype to a market-ready device.

- Select a pre-certified cellular module to simplify the manufacturing process.

- Choose a PTCRB-approved lab to conduct the required tests.

- Submit your test results and documentation to the board for approval.

- Receive certification, which confirms your device meets industry standards.

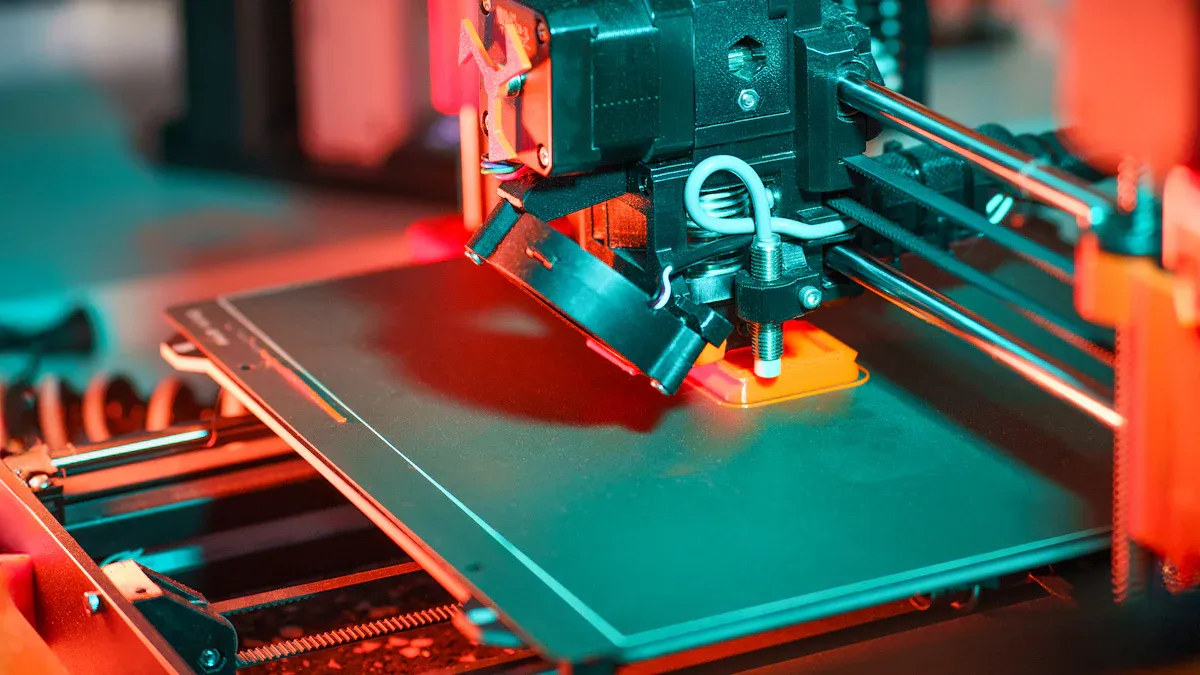

Phase 3: Production Validation Testing (PVT)

After validating your design, you enter Production Validation Testing (PVT). This phase is the final checkpoint before you begin mass production. Your focus shifts from validating the design to validating the manufacturing process. You use your actual production line to build a larger batch of units, ensuring you can manufacture your device at scale with consistent quality.

Validating the Process

You use PVT to confirm your manufacturing and assembly line works correctly. This is your first trial run using the full production process, equipment, and supply chain. The goal is to prove you can build the product efficiently and consistently. This validation step is crucial for identifying any issues in the manufacturing workflow before scaling production. A smooth production process ensures high production quality.

The Bridge to Full Production

PVT serves as the critical bridge for the transition to mass production. Unlike DVT, where you build a small number of units, PVT involves a larger run, often around 1,000 units. This larger scale tests your manufacturing line's ability to handle volume.

PVT: The Final Proving Ground 🏭 The main goal of this phase is to achieve mass production yields at mass production speeds. If the units you produce meet all quality requirements, you may even sell them. This proves your manufacturing process is ready for a full-scale launch.

Establishing QA Protocols

You must establish and refine your Quality Assurance (QA) protocols during PVT. At this scale, you can test your quality control systems under real conditions. You check for defects, ensure consistency, and confirm every device meets your quality standards. Strong quality control is essential for successful mass production. This focus on quality control helps you maintain high quality throughout the manufacturing journey.

Analyzing Production Yield

You need to analyze your production yield carefully. Yield is the percentage of non-defective products that come off your assembly line. A low yield during PVT signals problems in your manufacturing that you must fix before starting mass production. Optimizing your line to improve yield is key to achieving production efficiency and profitability at scale. This analysis ensures your quality control and manufacturing processes are ready for scaling production.

Phase 4: Scaling to Mass Production

You have validated your design and your production process. Now, you are ready for the final phase: scaling to mass production. This is where you increase your manufacturing volume to meet market demand. A successful launch depends on your ability to manage this large-scale operation effectively.

Ramping Up for Launch

You begin ramping up your manufacturing lines for the official product launch. This stage involves a significant increase in production speed and volume. Your goal is to build enough inventory to satisfy initial customer orders. This is the culmination of all your planning for mass production. The entire manufacturing team works to hit targets for a smooth market entry. This final push in scaling production is critical.

Supply Chain and Logistics

Your supply chain must be robust to support manufacturing at this scale. You need to coordinate with all your suppliers to ensure a steady flow of components. Efficient logistics are essential for moving parts to the factory and finished goods to distributors. Managing this complex network is a key challenge of mass production. A well-organized supply chain prevents delays in the manufacturing process.

Quality Control at Scale

Maintaining quality during mass production is a major focus. As you increase volume, you must have strong quality control systems. Defects are measured in Parts Per Million (PPM). Modern manufacturing aims for extremely low defect rates to ensure high product quality. Your quality control team must monitor the line constantly to catch issues before they affect a large number of units.

Quality Benchmark: Six Sigma Defect Rates (PPM) Your quality control goals should align with industry standards. A higher Six Sigma level means better quality.

Six Sigma Level PPM Defect Rate Level 4 6,210 Level 5 233 Level 6 3.4

Post-Launch Management

Your work continues after the product launches. You must address post-launch issues like software bugs or unexpected battery drain, which can frustrate users. Effective post-launch management is crucial for customer satisfaction and brand reputation. This includes providing regular software updates to improve performance and quality. You should establish a clear plan for ongoing support.

- Establish an update schedule: Plan regular updates to fix bugs and add features.

- Use automated tools: Deploy updates efficiently to all devices.

- Monitor feedback: Use real-time data to identify new problems.

- Leverage Enterprise Mobility Solutions (EMS): Centralize device management to enhance security and ensure compliance.

This proactive approach to quality control and support is essential for the long-term success of your mass production efforts. Scaling production is just the beginning; sustained manufacturing excellence keeps you competitive.

You can achieve successful mass production with a clear plan. The sample-to-mass production workflow guides your manufacturing journey. Your manufacturing success depends on mastering each phase.

- Prototyping: You create a sample and apply early DFM for better quality.

- DVT: You validate the design with stress tests to ensure quality.

- PVT: You validate the manufacturing process to prepare for mass production.

- MP: You scale manufacturing for launch while maintaining high quality.

Future mobile manufacturing will use more automation and AI for quality control. A disciplined sample-to-mass production workflow is your key to successful mass production. This approach ensures quality and prepares you for mass production.

FAQ

Which manufacturing phase is the most important?

You should view every phase as critical. Each stage builds on the last one. Skipping a step introduces major risks to your project. A disciplined approach ensures a successful launch and high-quality mass production.

How long does the entire sample-to-mass production process take?

The timeline varies based on your product's complexity. A typical mobile device project can take 12 to 18 months from concept to mass production. Advanced designs like foldable phones may require more time.

What is the main difference between DVT and PVT?

You use DVT to test your product's design. You use PVT to test your manufacturing process.

DVT vs. PVT 🎯

- DVT: Focuses on the "what" (your design).

- PVT: Focuses on the "how" (your factory line).

Why is Design for Manufacturability (DFM) so important?

DFM helps you design a product that is easy and affordable to build. You apply DFM early to avoid expensive changes later. This practice improves production efficiency and overall product quality during mass production.