Reduce transit damage with drop tests in 2025

Hospitality businesses can reduce transit damage costs in 2025. A systematic drop testing protocol is the most effective strategy. This guide presents a clear path for managers, not engineers, to improve their packaging. It empowers any team to protect goods during transit. The hospitality industry can achieve better outcomes with a simple framework.

This process involves four key steps:

- Identifying high-risk products.

- Selecting correct test standards.

- Executing tests properly.

- Using data to optimize packaging.

Identify high-risk products

A systematic approach begins with identifying which products need the most attention. Businesses can focus their resources effectively by pinpointing items with the highest risk of transit damage. This process saves time and money. It ensures that testing efforts yield the greatest return.

Categorizing by fragility

Managers first categorize inventory based on fragility. Certain items are inherently more susceptible to damage from drops, impacts, and vibrations. A clear understanding of these categories helps prioritize testing.

Common high-risk items in the hospitality sector include:

- Glassware and Ceramics: Wine glasses, plates, and decorative vases.

- Electronics: Televisions, tablets for ordering, and point-of-sale systems.

- Furniture with delicate components: Items with glass tops or intricate woodwork.

- Decor: Framed art, mirrors, and lighting fixtures.

Analyzing damage points

After categorizing products, the next step is to analyze historical data. Reviewing past shipping and returns information provides powerful, data-driven insights. This analysis reveals recurring damage patterns before they become larger problems.

A proactive analysis of returned items turns a cost center into a valuable data source for packaging improvement.

Implementing quality control checks for each returned item helps identify the root cause of damage. A major electronics company reduced its returned items by 20% after improving its returns inspection process. Hospitality businesses can achieve similar results by tracking key metrics.

| Data Point to Analyze | Actionable Insight |

|---|---|

| Carrier Damage Rates | Select carriers best suited for fragile shipments. |

| Product Return Reasons | Pinpoint specific product or packaging weaknesses. |

| Seasonal Damage Spikes | Adjust packaging for temperature or humidity changes. |

Select the right test standards

Choosing the right test standards gives businesses a reliable benchmark for package performance. These established protocols create consistent and repeatable test conditions. They provide the data needed to make informed packaging decisions.

Key standards for the hospitality industry

Several organizations publish standards relevant to the hospitality industry. These standards simulate common shipping hazards. Managers can select a test that mirrors their product’s journey through the logistics network.

| Standard | Focus Area | Best For |

|---|---|---|

| ISTA 1A | Basic Integrity | Packaged products under 150 lbs (68 kg). |

| ASTM D999 | Vibration Damage | Items sensitive to shaking during transport. |

| ISO 2247 | Low-Pressure Effects | Shipments traveling via air freight. |

Using these standards provides a solid foundation. It helps teams compare the performance of different packaging designs objectively.

Adapting for modern supply chains

Standard tests are a great start, but the 2025 supply chain presents unique challenges. Today’s complex logistics demand a more tailored approach. The modern logistics journey involves more touchpoints than ever before.

A package may move from a human to a robot, onto multiple trucks, and through several sorting centers. Each step in the logistics process introduces a new risk.

Managers must consider these modern logistics realities. Automated conveyor systems can cause side impacts and abrasions. The rise of multi-point logistics increases the total number of drops a package endures. A successful logistics strategy accounts for these factors. Businesses should also analyze the shipping environment. Extreme heat or humidity can weaken cardboard and adhesives. Adapting tests for these specific logistics challenges is crucial for any company in the hospitality industry. This proactive view of logistics ensures packages are truly ready for their real-world journey. Strong logistics partnerships can provide data to refine these tests.

Execute the drop test protocol

With high-risk products identified and standards selected, the team can now execute the drop test. This practical phase generates the data needed for meaningful packaging improvements. A consistent protocol ensures that every test is reliable and repeatable.

Performing the drop test

Proper execution requires specific tools to create a controlled free-fall drop. This removes guesswork and ensures the test simulates real-world impacts accurately. Professional testing relies on dedicated machinery.

- Drop Test Machine

- Package Drop Tester

- Drop Tester

The testing process itself follows a clear, structured sequence. Following these steps ensures that the results are valid and comparable across different packaging designs.

- Prepare the equipment. The team inspects the drop test machine to confirm it is clean, stable, and functioning correctly.

- Select the test sample. They choose a fully packed product, sealed as it would be for actual shipment.

- Set the drop height and angle. The team uses the chosen standard (like ISTA 1A) to determine the correct drop height based on package weight. They also identify the required impact surfaces, such as a flat base, a corner, or an edge.

- Secure the package. The package is mounted on the machine, aligned for the first scheduled drop.

- Conduct the test. The team releases the package and repeats the process for all required drops and orientations.

Evaluating pass/fail criteria

After the final drop, the team evaluates the outcome. The condition of the product inside—not just the box—is the ultimate measure of success. A damaged box that protects its contents may be a success.

A package passes the test only if the product inside remains fully functional and free from cosmetic damage.

Clear criteria are essential for an objective assessment. This simple framework helps teams decide if the packaging passed or failed.

| Condition | Result |

|---|---|

| Product is undamaged and functional. | ✅ Pass |

| Packaging shows scuffs but is intact. | ✅ Pass |

| Packaging is punctured or torn. | ❌ Fail |

| Product has cosmetic or functional damage. | ❌ Fail |

Documenting these results with photos and notes is critical. This data provides the foundation for the final step: optimizing the packaging design.

Optimize packaging to reduce transit damage

A failed drop test is not a setback; it is a valuable data source. This data empowers teams to refine their packaging and reduce transit damage. The goal is to create a protective design that is both effective and economical.

Analyzing test failures

A systematic inspection process turns test failures into clear insights. After each drop, the team should meticulously inspect the package and product to pinpoint weaknesses.

Common failure points include:

- Punctures: The product pierces the packaging material.

- Seal Flexing: Heavy items cause seals to crack or pop open.

- Improper Sizing: Too much empty space allows the product to shift and abrade against the container.

Analyzing these patterns helps identify the root cause of the damage. This analysis guides decisions on packaging improvements, from material selection to structural design.

Implementing cost-effective solutions

Drop test data helps engineers select optimal materials and create a better packaging design. The right packaging balances protection and cost, preventing unnecessary expenses from over-engineering or product returns. Many modern solutions offer superior protection without high costs.

| Solution | Primary Benefit |

|---|---|

| Engineered Foam Inserts | Custom-fit cushioning for high-fragility items. |

| Reinforced Corner Guards | Protects vulnerable edges from impact. |

| Air Pillows | Fills empty space to prevent movement. |

Choosing the correct corrugated board strength is another critical decision. It ensures the box can support the product's weight throughout the supply chain. This strategic choice helps optimize transport and protect the company's bottom line.

Integrating sustainable materials

Modern sustainability goals do not require a compromise on protection. Many new packaging materials offer excellent shock absorption while being environmentally friendly. This approach helps the hospitality industry achieve better sustainable packaging outcomes.

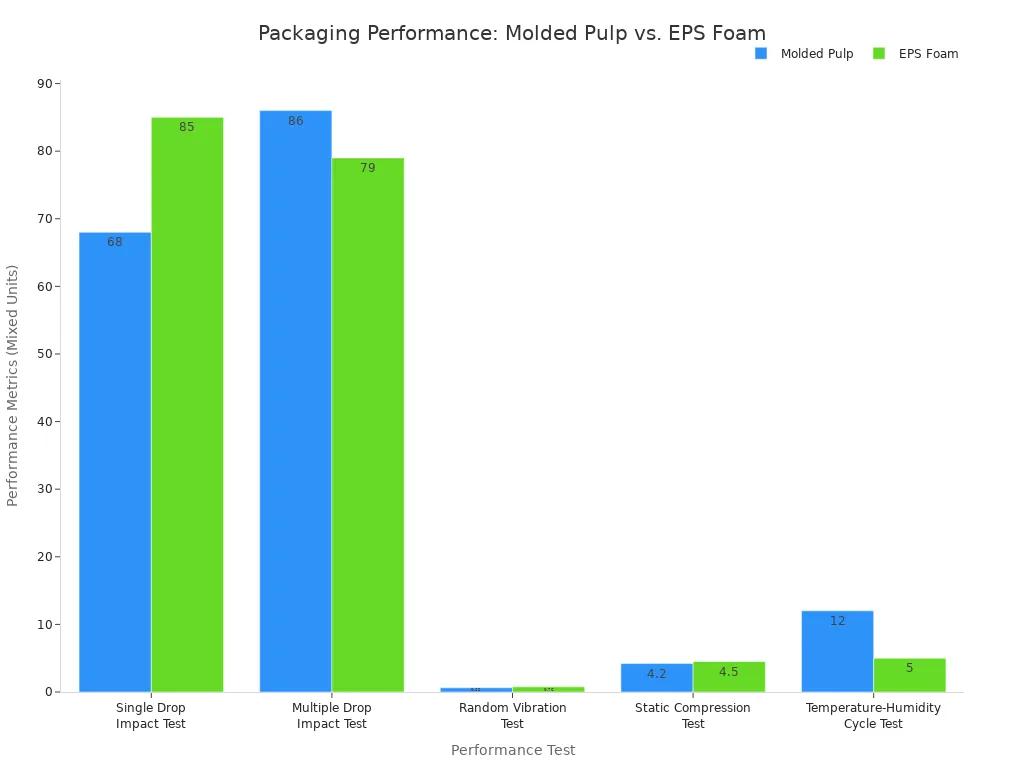

Options like molded pulp, honeycomb paper protectors, and fungal mycelium packaging provide remarkable impact resistance. For example, mushroom-based packaging can match the shock absorption of traditional foam. Molded pulp often shows superior performance in drop tests compared to EPS foam.

Integrating these materials into a new design supports corporate sustainability goals. It also provides excellent protection, ensuring products arrive safely.

A four-step action plan provides a clear path to reduce transit damage. It involves identifying risks, selecting standards, executing tests, and optimizing packaging. Consistent drop testing is the most direct way for hospitality businesses to cut costs. This process protects brand reputation by ensuring products arrive intact, which improves customer satisfaction. Better packaging also increases operational efficiency.

Start implementing your drop test protocol today to ensure your products arrive intact in 2025.

FAQ

How does drop testing support sustainability goals?

Drop testing helps businesses optimize packaging. This process reduces packaging waste and the need for returns. Better packaging design supports sustainability and a circular economy. It lowers the overall environmental impact of a product's delivery. The environment benefits from less packaging waste.

What is the role of logistics in packaging design?

Modern logistics involves many touchpoints. Each step in the logistics process tests a package's strength. Data from logistics partners helps refine packaging for a specific delivery journey. A successful delivery depends on understanding the logistics chain. This knowledge ensures a safe delivery and better logistics.

Good packaging accounts for every stage of logistics. A safe delivery requires planning for the entire logistics journey. The final delivery reflects the quality of the logistics and packaging.

Can small businesses afford drop testing?

Yes. Businesses can start with simple, manual tests. These tests provide valuable data without large investments. The savings from reduced damage often outweigh the initial cost. This makes testing a smart financial decision for any business in the hospitality industry.

How does the packaging industry support a circular economy?

The packaging industry develops new materials. These materials are often reusable or recyclable. This focus on circular design reduces packaging waste. The industry's push for sustainability and circular solutions helps the environment. These new materials improve packaging performance for every delivery.