The Environmental Benefits of Using Recycled Acrylic Sheets in Your Projects

Introduction: Why Sustainability in Materials Matters

Sustainability is no longer a buzzword—it's a core driver in material selection for leading brands, designers, and businesses worldwide. The plastics industry alone is responsible for 3.4% of global greenhouse gas emissions, according to the Ellen MacArthur Foundation, and policymakers across North America, Europe, and Asia-Pacific are accelerating mandates to drive recycled content and circularity. Choosing the right sustainable materials isn’t just about image: it’s about reducing operational footprints, meeting new regulatory standards, and satisfying end-user demands for transparency and environmental stewardship.[^1]

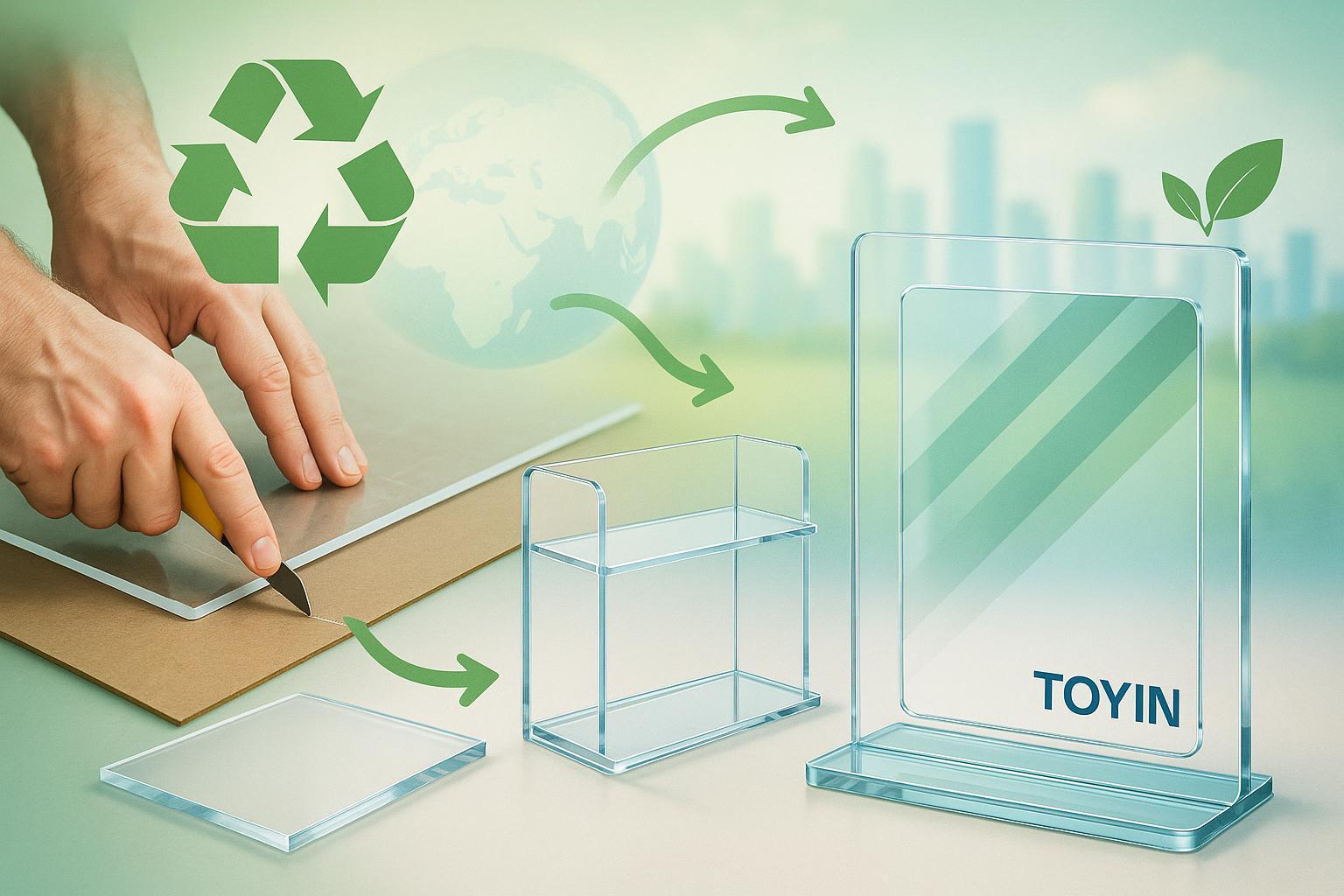

Acrylic (PMMA) is prized for its clarity, durability, and versatility. But with over 1.5 million tons produced annually, the pressure is on to find ways to reduce its environmental impact across the value chain. Enter recycled acrylic sheets—next-generation materials that close the resource loop, dramatically cut carbon, and allow for stunning, functional design. This guide explores the full environmental and business advantages of moving to recycled acrylic—and how integrated solutions, such as those from Toyin Acrylic Products Co., Ltd. (TOYIN), make it smarter and easier than ever to go green.

[^1]: Ellen MacArthur Foundation – Plastics and Climate

Understanding Recycled Acrylic Sheets

What Are Recycled Acrylic Sheets?

Recycled acrylic sheets are panels primarily composed of reclaimed PMMA (polymethyl methacrylate) either from post-industrial or post-consumer sources, processed and purified to recreate sheets equal in clarity, strength, and workability to those made from virgin resin. Globally, their production is governed by standards such as ISO 59004 and SCS Global’s recycled content certification.[^2]

The Manufacturing Process in Brief

Collection: Used acrylic products and fabrication scrap are collected.

Sorting and Cleaning: Material is sorted, cleaned, and prepared for recycling.

Depolymerization: PMMA is broken down into its MMA monomer through controlled chemical methods.

Purification: The MMA monomer is purified, filtering out contaminants and dyes.

Repolymerization: Purified monomer undergoes a polymerization process to form new acrylic sheets.

Visual Aid: Infographic—The Circular Lifecycle of Recycled Acrylic: Scrap → Depolymerization → Monomer Purification → Sheet Production → New Project Installation.

Certified Sustainability

Fully certified recycled content is validated through third-party chain-of-custody protocols, mass balance accounting, and annual audits in line with SCS, GRS, and ISO 14001 standards.[^3]

Key Standards:

ISO 59004: Defines recycling and recycled content for plastics

Properties and Performance

Modern recycled acrylic achieves the same mechanical and optical properties as virgin sheets, making it suitable for displays, signage, furniture, and more—without compromises in clarity or durability.[^4]

[^2]: SCS Global Services – Recycled Content Certification [^3]: GRS – Global Recycled Standard [^4]: Acrylic Design Associates – LCA Study

Lifecycle Environmental Benefits: Quantifying the Impact

Resource and Carbon Savings

Carbon Footprint:

Recycled acrylic produces over 90% less CO2 compared to virgin acrylic sheets.

Virgin acrylic: 45,000-46,660 kg CO₂e per ton

Recycled acrylic: ~5,300-5,400 kg CO₂e per ton[^5]

Energy Savings:

Up to 70% less energy is required to produce recycled acrylic.

Water Use:

Water savings range from 20–40% across various manufacturing models.

Oil Diversion:

Every 100kg of recycled acrylic saves approximately 200–250 liters of crude oil.

(See the bar chart below for a visual comparison.)

Indicator | Virgin Acrylic | Recycled Acrylic | Relative Savings |

|---|---|---|---|

Carbon Output (kg CO₂/ton) | 45,000–46,660 | 5,368 | ~90% |

Energy Input (MJ/ton) | 95,000+ | 28,000 | 60–70% |

Water Consumption (L) | High | Moderate | 20–40% |

Oil Required (L/100kg) | 250+ | <50 | 80%+ |

Data sources: PlasticsEurope, Acrylic Design Associates, Recrylic LCA Studies.[^5]

Closing the Loop: Minimizing Landfill & Pollution

Recycling acrylic keeps valuable PMMA out of landfills and waterways, directly reducing microplastic leaks and helping build a circular plastics economy. This supports global sustainability goals—such as EU and UN targets for plastics reuse and recycling.[^6]

[^5]: PlasticsEurope LCA Dashboard [^6]: OECD Circular Plastics Report 2023

Comparing Recycled vs. Virgin Acrylic: Performance and Environmental Impact

Parameter | Virgin Acrylic | Recycled Acrylic |

|---|---|---|

Optical Clarity | ★★★★★ | ★★★★★ |

Impact Resistance | ★★★★☆ | ★★★★☆ |

Workability/Machinability | ★★★★★ | ★★★★★ |

UV Resistance | ★★★★☆ | ★★★★☆ |

Environmental Footprint | ★ | ★★★★★ |

Price (Market Avg.) | $$ | $–$$ |

Certifications Available | Some | Yes (ISO, SCS, GRS) |

Customizability | ★★★★★ | ★★★★★ |

Key Takeaway:

For most commercial and design applications, recycled acrylic matches the performance of virgin material while offering major environmental and sometimes cost benefits.[^7]

Potential Limitations:

Sourcing must focus on certified recycled sheets to avoid quality/traceability issues.

Slight color variance may appear in unpigmented batches (rare with premium suppliers).

[^7]: Mindful Design Consulting – Recycled Acrylic Guide

Certifications, Standards, and Regulatory Compliance

Why Certification Matters

Eco-certifications ensure environmental claims are credible and auditable—critical for both regulatory compliance and brand reputation.

Major International Standards

ISO 14001: Environmental management systems

ISO 59004: Definitions for recycled plastics & content

SCS Global Recycled Content: Third-party verification

Global Recycled Standard (GRS): Chain-of-custody & recycled input

LEED (US Green Building Council): Credits for recycled content materials

RoHS (EU): Hazardous substance controls

How to Verify Compliance (Step-by-Step)

Request certificates of analysis and SCS/GRS chain-of-custody verification.

Ensure suppliers use mass-balance accounting and track recycled input percentage.

Confirm annual third-party audits (ask for recertification documents).

Collect full LCA and emission data for your sustainability reporting.

Real-World Example: TOYIN’s Certified Chain

Toyin Acrylic Products Co., Ltd. (TOYIN) operates under strict quality protocols—ISO9001 certification, eco-friendly R&D/production, and validated recycled content tracking. Their products’ documentation supports global LEED, GRS, and ISO-compliant project delivery.

For tips on specification and documentation: see the downloadable SCS Recycled Content checklist here.

Practical Applications and Case Studies

Leading Use Cases

Retail and Brand Displays: Sustainable shopfitting, luxury window displays, branded organizers

Signage and Fixtures: Durable indoor/outdoor signs, museum mounts, event backdrops

Furniture and Interiors: Office partitions, home organizers, hospitality accent pieces

Protective Barriers and Trophies: Safe, transparent shields; custom-brand awards

Success Story: Life Time Health Clubs

Life Time, a major US fitness brand, partnered with Recrylic to install recycled acrylic privacy screens at 130 locations. The result:

304 tons of CO₂ saved (equal to removing 59 cars per year)

643 barrels of oil not consumed

Full third-party certification, showcased publicly for member confidence[^8]

Brand-Ready Custom Solutions: TOYIN in Action

With 20+ years of expertise, TOYIN has delivered custom recycled acrylic products for international retailers, global OEMs, designers, and event organizers:

Display Boxes and Organizers: Sustainably branded for retail and luxury sectors

Signage & Shopfit Displays: Fully customizable with global shipping

Trophies & Custom Furniture: Combining eco-performance with innovative design

TOYIN’s advanced automation, strict QC, and environmental certifications guarantee both performance and compliance—making them a trusted partner for forward-thinking businesses.

[^8]: Acrylic Design Associates – Case Study

How to Source and Specify Recycled Acrylic (with TOYIN as Solution Partner)

A Step-by-Step Procurement & Specification Guide

Define Project Needs: Is recycled acrylic suitable for your functional, design, and sustainability goals?

Vet Suppliers for Certification: Insist on ISO, SCS, or GRS documentation. TOYIN provides all certificates upon request.

Request Technical Data: Ask for full LCA results, recycled content verification, and sample sheets.

Review Customization Capability: Leverage TOYIN’s rapid quoting and wide design flexibility—from color options to shapes and finishes.

Check Regulatory Compliance: Make sure the material meets LEED, RoHS, and local building codes.

Ask for Chain-of-Custody Proof: Audit trails and certification renewals are crucial for due diligence.

Order Pre-Production Samples: Confirm performance, clarity, and finish before full production.

Specify Takeback/Closed-Loop Programs: Sustainable partners like TOYIN will help set up recycling and future repurchase options.

Download a Sourcing & Compliance Checklist or Contact TOYIN for Custom Consultation and Samples

Why TOYIN?

Full Customization: From design to delivery, across displays, organizers, retail furniture, and more

Certified Recycled Content: Documentation for global projects

Rapid Global Logistics: Just-in-time for event, retail, and OEM timelines

Eco-Leading Manufacturing: Precise cutting, efficient processes, and eco-compliance at every step

Call to Action: Ready to integrate high-performance recycled acrylic into your project? Consult TOYIN for sustainable, custom solutions — your global partner in environmentally responsible acrylic manufacturing.

Conclusion & Action Steps

Recycled acrylic sheets offer verified reductions in CO₂, energy, and oil consumption—all while meeting or exceeding the performance of conventional materials. For brands, designers, architects, and sustainability managers, switching to certified recycled acrylic is one of the most straightforward ways to deliver on both environmental goals and business value.

Take the Next Step:

Download specification checklists

Request custom samples or project consultations from TOYIN

Track regulatory updates and new global certifications to keep your projects future-ready

By choosing recycled acrylic—especially via a fully certified supplier like TOYIN—you become part of a circular economy movement that puts people, planet, and performance first.

References