From Sample to Scale Prototyping to Rollout Guide

You face immense pressure in event production. Only 8.5% of projects finish on time and on budget. A successful prototyping to rollout plan avoids a single leap. The transition from prototype to production needs a structured process for scaling. This framework for transitioning from prototype to production has three pillars. You will use a strategic prototype, validate with a pilot run, and manage the mass production. This method makes the path from prototype to mass production a clear journey to scale and quality for any mass production.

The Prototyping to Rollout Framework

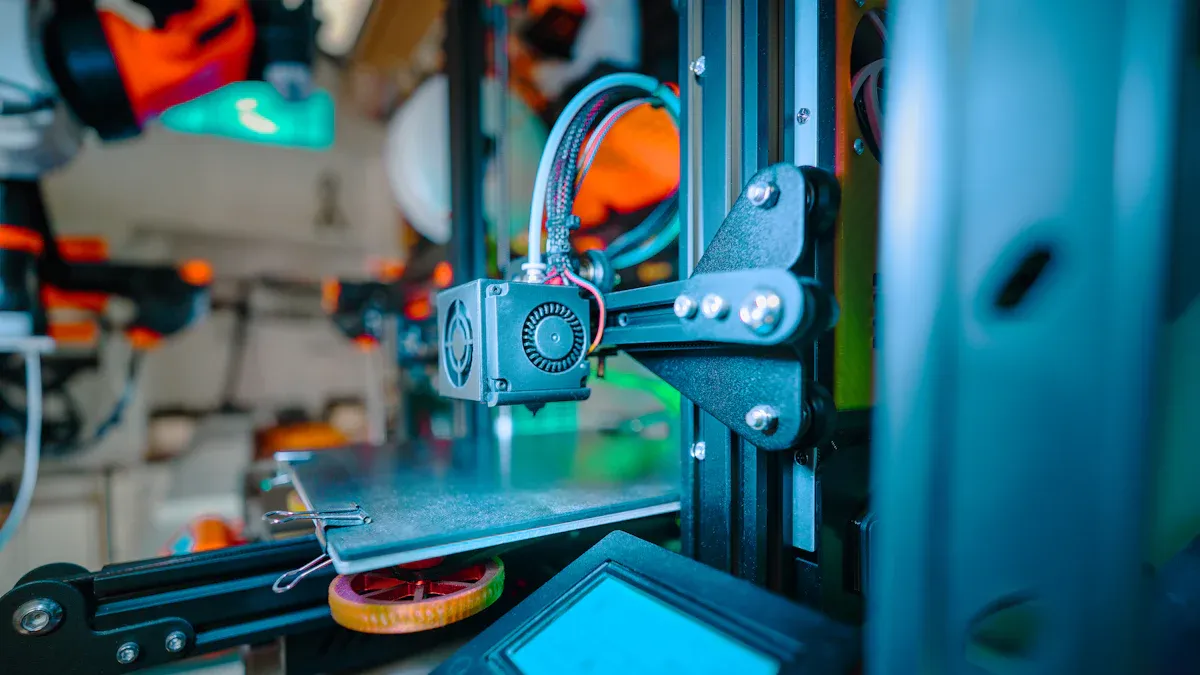

Your prototyping to rollout journey begins with a strategic mindset. You should not see a prototype as just a model. Instead, view it as the first step in your production process. This phase is for design validation, material testing, and cost estimation. Prototyping with production in mind ensures a smoother transition from a single sample to mass production.

The 'Production-Intent' Prototype

You need to create a 'production-intent' prototype. This prototype is nearly identical to your final market-ready product. It uses the same manufacturing processes and materials planned for mass production. This step is your final validation check before you scale. Creating this advanced prototype allows your team to:

- Test how components fit and function together.

- Confirm the design meets performance and safety standards.

- Get a clear understanding of your final production costs.

Fixing a flaw in the prototype is much cheaper than fixing it after tooling is complete. This prototype helps you identify issues before they become expensive problems in mass production.

Design for Manufacturability (DFM)

You should apply Design for Manufacturability (DFM) principles to your prototype. DFM is the process of designing products for easy manufacturing. This approach helps you reduce costs and shorten your time-to-market. Simple changes can make a big impact on the production line. For example, you can:

- Minimize Part Count: Fewer parts reduce material costs and assembly time.

- Standardize Components: Using standard parts streamlines inventory and leverages economies of scale.

These DFM strategies optimize your prototype for efficient manufacturing and a successful transition to mass production.

Creating the 'Golden Sample'

Your final, approved production-intent prototype becomes the 'Golden Sample'. This sample is the perfect example of your product. It serves as the definitive quality benchmark for the entire mass production run. Every unit from the factory will be compared against this prototype.

It is a best practice to keep multiple approved copies of the golden sample. You should have one for the factory, one for your internal team, and one for your inspection company.

This single prototype sets clear expectations and prevents misunderstandings. It is the most important tool you have to ensure production quality and consistency as you move from prototype to mass production.

Pilot Runs: Bridging Prototype to Mass Production

Your approved 'Golden Sample' prototype is ready. Now you must bridge the gap between that single prototype and full mass production. This is where a pilot run becomes essential. A pilot run is a small-batch production that acts as a dress rehearsal for scaling. This critical transition step helps you test your manufacturing processes on a smaller scale, lowering financial risk before you commit to a large investment. This phase is your final validation before scaling to mass production.

Selecting Manufacturing Partners

Choosing the right partner is crucial for a seamless transition from prototype to mass production. You need a manufacturer who understands the pressures of event timelines. When vetting partners, you should evaluate their:

- Capabilities: Assess their track record, technical capacity, and past work.

- Reputation: Check client testimonials and industry reviews for reliability.

- Experience: Ask how they manage tight deadlines and unexpected logistical delays.

A good partner helps ensure your prototyping to rollout plan succeeds. Their expertise in manufacturing is vital for your production.

Validating the Path from Prototype to Production

A pilot run validates your entire production process. It confirms your prototype design is mature and ready for mass manufacturing. During this run, you can test everything with the actual equipment and components planned for mass production. This allows you to identify bottlenecks and refine quality control checks before scaling production.

Your goal is to confirm readiness for mass production. A successful pilot run shows that your manufacturing processes can deliver quality at scale.

You should confirm that:

- The assembly line and trained workers are prepared for the production.

- The rate of defective products is acceptably low.

- The production line can run at the expected speed to prevent shipment delays.

This small-scale production run provides real-world data, giving you confidence in your plan for scaling. It is the best way to ensure a smooth transition to mass production.

Finalizing the BOM & Production Specs

The pilot run is your last chance to finalize the Bill of Materials (BOM) and production specifications. An accurate BOM lists all raw materials, components, and sub-assemblies for your prototype. This detailed document is fundamental for managing costs and your supply chain in mass production. A precise BOM helps you budget accurately and maintain profit margins. It prevents over-purchasing and avoids delays caused by component shortages during production. Finalizing these details after the pilot run ensures your transition to mass production is efficient and cost-effective. Your prototype is now fully prepared for the market.

Scaling to Full Mass Production

You have validated your design and manufacturing processes. Now you begin scaling to full mass production. This final transition is where your planning pays off. Scaling production requires careful management to maintain quality and meet deadlines. Your focus shifts to executing the mass production plan, managing logistics, and preparing for any unexpected issues. Success at this scale depends on strong quality control and a resilient supply chain. This is the final step in bringing your market-ready product to the mass market.

Quality Control for Mass Production

You must maintain strict quality control during mass production. Your 'Golden Sample' prototype is the ultimate guide for this. Every unit coming off the line should match this perfect prototype. You can establish clear quality control standards to ensure consistency.

- Standardize Processes: You should document every production step. This reduces errors and ensures each prototype is made the same way.

- Inspect Materials: You need to perform regular checks on incoming raw materials. This prevents defects before production even starts.

- Train Your Team: Your workers need training on quality standards. They must know how to identify a product that does not match the approved prototype.

This focus on quality control ensures the final mass production run meets the standards set by your initial prototype. Consistent quality control is key for a successful scaling for mass production.

Event Logistics & Supply Chain

Your production is scaling, so you must manage event logistics. A seamless transition from the factory to the event venue is critical. You need to coordinate with multiple suppliers to ensure timely deliveries.

A just-in-time delivery strategy can prevent on-site clutter. You can rent local warehouse space to pre-sort materials and control delivery times. This gives you more control over your inventory.

Clear communication with your logistics partners helps you track shipments. This ensures all components for the mass production arrive on time. Proper supply chain management is essential for a smooth event rollout and scaling production.

Mitigating Common Production Risks

You should prepare for common production risks. Issues like shipping delays or material shortages can threaten your timeline. A good risk mitigation plan helps you manage these challenges. You can build a resilient supply chain to avoid disruptions.

One key strategy is to diversify your suppliers. You should not rely on a single source for critical components. This gives you a backup if one supplier has a problem. This approach is vital for scaling production without interruption. Having a plan for these risks protects your investment and ensures your mass manufacturing and mass production efforts succeed. It is the final check for your prototype to mass production journey.

Your prototyping to rollout journey transforms a single prototype into mass production. You start with a 'Golden Sample' prototype, validate this prototype with a pilot production run, and manage the final mass production. This structured transition from prototype to mass production is vital for your production. Many pilots fail to scale.

- Only 11% of companies successfully scale new initiatives.

This disciplined production approach turns your prototype into a successful production. Your prototype is ready for production. You can scale with confidence. This transition makes your prototype a competitive advantage, not a stressor for your production. This ensures your prototype leads to successful mass production and a great production run for your prototype.

FAQ

What is a 'Golden Sample'?

The 'Golden Sample' is your final, approved prototype. It becomes the perfect model for your product. You use this sample as the quality standard for the entire production run. Every unit made must match this sample to ensure consistency and quality.

Why is a pilot run necessary?

A pilot run tests your manufacturing process with a small batch. This step helps you find and fix problems before starting full production. It lowers your financial risk and confirms you can produce quality products at scale, preparing you for the market.

How does DFM help my project?

Design for Manufacturability (DFM) simplifies your product's design for easier manufacturing. You can use fewer parts or standard components.

This approach helps you:

- Lower production costs.

- Speed up your time to market.

- Improve overall product quality.

What is the biggest risk in scaling production?

The biggest risk is a loss of quality. As you increase volume, it becomes harder to maintain consistency. You can prevent this with strict quality control checks, clear process documentation, and a well-vetted manufacturing partner to protect your investment.