Understanding the Key Differences Between Perspex and Acrylic: What You Need to Know

Is Perspex just “acrylic” by another name, or is there more to the story? If you’re sourcing materials for a project—or balancing cost, quality, and customization—understanding the real differences between Perspex (as a premium cast acrylic brand) and generic acrylic sheets is essential for smart decision-making.

In this in-depth guide, we’ll walk you through the technical distinctions, application scenarios, pros and cons, and cost considerations. Plus, you’ll discover how custom manufacturers like Toyin Acrylic Products Co., Ltd. can deliver tailored solutions that fit your exact needs.

Myth-Busting: Is Perspex Just Acrylic?

Fact: Perspex is a brand name for high-quality cast acrylic. All Perspex is acrylic, but not all acrylic is Perspex!

Acrylic is the generic term for poly(methyl methacrylate) (PMMA), a transparent, thermoplastic material.

Perspex is a registered trademark (like Plexiglas or Lucite), specifically denoting cast acrylic of premium specification, produced with stringent quality controls and a well-established reputation—especially for signage, architectural, and outdoor uses.

“Perspex sheets are made using the cast process, offering excellent clarity and consistency, and a 10-year guarantee against UV yellowing.” (Simply Plastics Datasheet)

Other common acrylic types:

Generic cast acrylic (various brands, quality varies)

Extruded acrylic (cheaper, usually less optically pure)

Cast vs. Extruded Acrylic: Why It Matters

Property | Cast Acrylic (e.g., Perspex) | Extruded Acrylic (Generic) |

|---|---|---|

Manufacturing | Resin poured in molds | Melted & forced through dies |

Optical Clarity | Superior, glass-like | Good, but may have distortions |

UV Resistance | High, often 10-year warranty | Lower, unless UV stabilized |

Thickness Consistency | Excellent | More variation |

Price | Higher | Lower |

Abrasion Resistance | Excellent | Fair; scratches more easily |

Suitability | Premium signage, displays | Budget, indoor, disposable |

Cast acrylic delivers the best clarity, durability, and UV resistance (ASTM D4802-16). Brands like Perspex invest in strict controls, so their products perform predictably in demanding environments.

Extruded acrylic is ideal where cost is the driver and ultra-premium optical clarity or long outdoor life are not mission-critical.

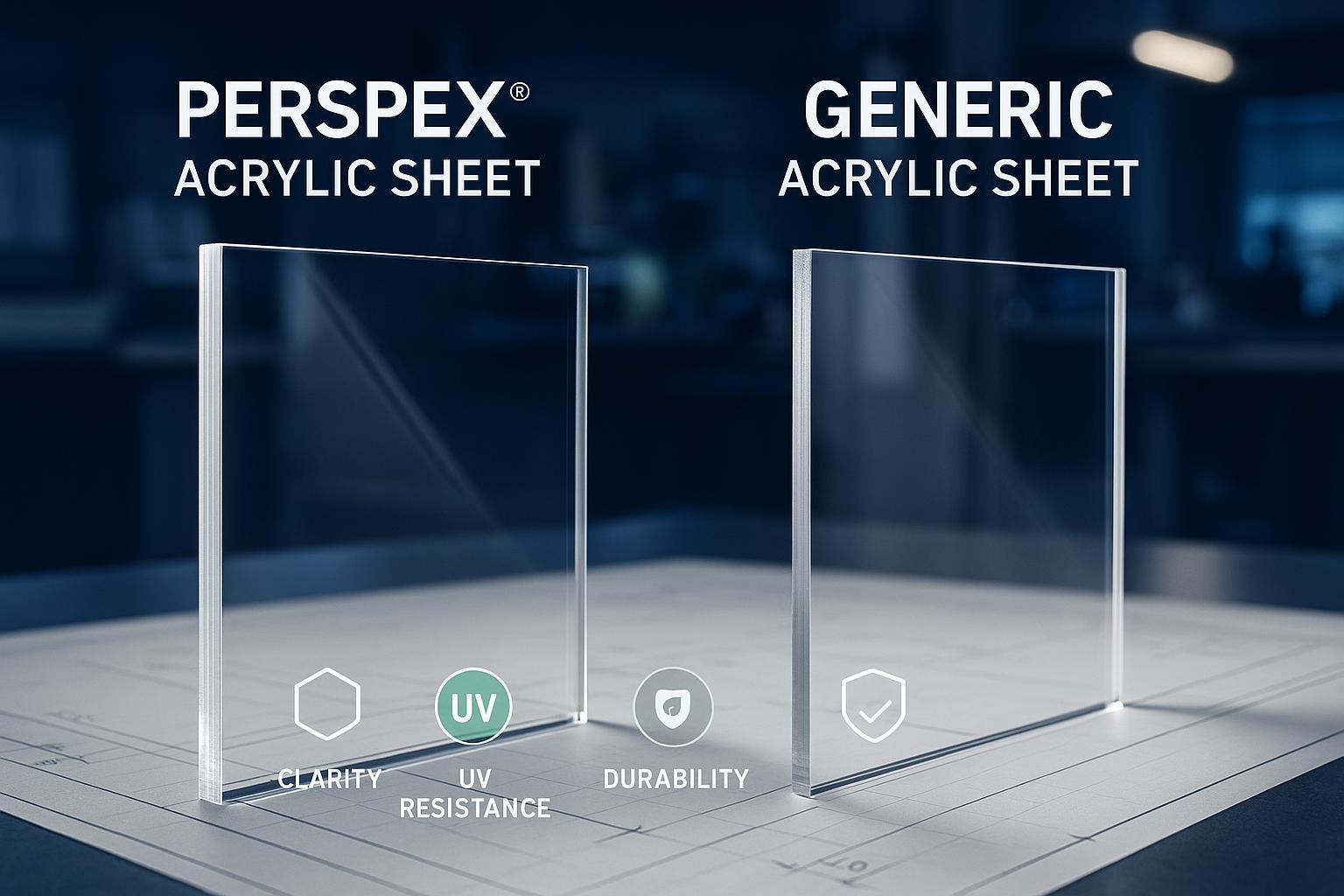

Performance Data: Clarity, UV Resistance & Durability

Perspex (Cast Acrylic)

Light Transmission: ~90%—nearly as clear as glass.

UV Resistance: 10-year guarantee; excellent weatherability (won’t yellow outdoors) (Perspex Product Page).

Durability: Reliable in temperatures from -40°C to 80°C; tough, impact resistant; surface comes with removable protective film.

Fire Rating: UL 94 HB/UK Class 3.

Generic Acrylic

Cast (non-branded): Often similar to Perspex if sourced from reputable suppliers, but quality can vary. Look for minimum 80% PMMA by ASTM standard.

Extruded: Slightly lower optical quality (~88% transmission); more prone to warping and yellowing unless specifically UV-stabilized (OwnPlastics Guide).

AR (Abrasion-Resistant): Some generics offer extra coatings for better scratch resistance (Tap Plastics).

Cost Comparison: What Should You Budget For?

Thickness | Perspex (USD/sq ft) | Generic Cast (USD/sq ft) | Extruded (USD/sq ft) |

|---|---|---|---|

1/16" | $6.50–$8.00 | $3.50–$5.00 | $2.50–$4.00 |

1/8" | $7.00–$9.50 | $4.00–$6.50 | $3.50–$5.50 |

1/4" | $9.00–$12.00 | $6.00–$8.50 | $5.00–$7.00 |

1/2" | $15.00–$20.00 | $10.00–$14.00 | $7.00–$11.00 |

Custom shapes, finishes, or fabrication can add $5–$15+/sq ft; bulk rates lower for large/bespoke orders.

Perspex and branded cast acrylic command a premium, justified in high-demand or outdoor projects. Generic acrylics shine for tight budgets and non-critical applications. (Alands Plastic Price Overview)

Decision-Making: Which Should You Choose?

1. Signage & Retail Displays

Outdoor, premium branding: Perspex or branded cast acrylic is the smart choice—visual clarity and UV protection matter for curb appeal and longevity.

Temporary, indoor, or budget signs: Generic extruded or cast acrylic works; check for surface finish and clarity.

2. Architectural Elements & Furniture

High-impact, customized installations: Opt for Perspex or premium cast materials. Thickness uniformity and strength are critical.

Fast prototyping/simple dividers: Generic sheets, especially from a reputable manufacturer, will deliver great value.

3. Consumer Projects, Art & Hobby

Laser cutting, crafts, organizational products: Generic cast acrylic is usually sufficient (be sure to confirm laser compatibility).

Aquariums, conservation science, high-clarity framing: Perspex or high-end cast acrylic preferred for clarity and long-term performance (Tandfonline Conservation Research).

4. OEM/Custom-Brand Manufacturing

High volume, branded, or private label: Work with a trusted manufacturer who can blend price and performance to your needs, such as Toyin Acrylic Products Co., Ltd.

Real-World Perspective: Custom Quality with Toyin Acrylic Products Co., Ltd.

Not all acrylic product suppliers are created equal—especially when it comes to tailoring design, scale, and brand requirements. Toyin Acrylic Products Co., Ltd. offers a compelling alternative to standard Perspex and generics:

Custom Solutions: From display boxes, trays, and trophies to furniture and signage, Toyin specializes in end-to-end design, R&D, and scalable production of acrylic products.

Premium Materials: Uses high-transmittance imported acrylic, matching (and sometimes exceeding) the quality of well-known brands for many applications.

Strict Quality Control: ISO-certified processes, rapid quoting, and eco-friendly manufacturing.

Global Service: Fast turnarounds, worldwide logistics, and a proven track record with brands, OEMs, and individual creators.

“Our clients consistently receive acrylic solutions that blend striking clarity with precision engineering—whether for luxury brand displays or custom organizational systems.” – Toyin Customer Testimonial

—

Summary Matrix: Choosing Between Perspex, Generic Acrylic, and Custom Solutions

Scenario / Need | Perspex (Cast) | Generic Acrylic (Cast/Extruded) | Custom (e.g., Toyin) |

|---|---|---|---|

Top-tier clarity, outdoor use | ✓✓✓ | ✓/△ | ✓✓✓ (if specified) |

Budget, indoor/short-term use | △ | ✓✓✓ | ✓✓ (basic models) |

Large creative/custom project | ✓/△ | ✓/△ | ✓✓✓ |

Speed, design flexibility | △ | ✓✓ | ✓✓✓ (rapid, tailored) |

Eco-friendly/quality controls | ✓✓ | △/✓ | ✓✓✓ |

Brand/OEM collaboration | △ | ✓ | ✓✓✓ (branding, design) |

✓✓✓ = Ideal; ✓✓ = Good; ✓ = Sufficient; △ = Possible but less preferred

Frequently Asked Questions (FAQ)

1. Is it worth paying extra for Perspex for retail projects?

If long-term appearance, UV resilience, and visual impact count, yes. Otherwise, quality generics offer economy for “fast change” displays.

2. Can you use cast and extruded acrylic together in the same installation?

Technically possible, but differences in thickness and color finish may be noticeable in close inspection. Stick to one type for the most cohesive look.

3. What about environmental/flexibility concerns?

Recyclable acrylic (including brands like Perspex®re) and eco-first manufacturers like Toyin are advancing sustainability in the industry.

Need Customization, Quality, or Scale? Partner with TOYIN

If your business or project demands reliable, tailored, high-quality acrylic products—whether you’re inspired by Perspex-level performance or need creative fabrication—Toyin Acrylic Products Co., Ltd. combines technical expertise, deep customization, and global support. Discover how TOYIN can bring your next project to life with precision and confidence.

References: