Your Guide to Luxury Watches & Jewelry Production

The production of luxury watches & jewelry follows a meticulous, multi-stage workflow. This luxury process is essential for luxury brands. It transforms a creative concept into a market-ready luxury good. Consumers drive this focus; 70% cite material quality and 61% cite craftsmanship as key to a luxury purchase. The journey ensures every luxury item meets luxury standards. The five key phases for creating these luxury goods are:

- Design & Specification

- Prototyping & Sourcing

- Sample Refinement

- Mass Production & QA

- Final Assembly & Rollout

This structured path is fundamental for all luxury brands to maintain the integrity expected in the growing luxury market.

DESIGNING LUXURY WATCHES & JEWELRY

The design phase is the genesis of every luxury product. It transforms an abstract vision into a tangible blueprint. This initial stage sets the standard for the final luxury item.

CONCEPTUALIZATION AND SKETCHING

Every luxury creation starts with an idea. Designers draw inspiration from countless sources. Architecture, nature, and history often influence the final form of a luxury piece. This creative process gives each luxury item its unique story.

Inspiration in Luxury Design Many famous luxury timepieces find their roots in the world around us.

- The Corum Golden Bridge Stream mimics the lattice structure of the Golden Gate Bridge.

- The Jaeger-LeCoultre Reverso reflects the iconic Art Deco geometry of the Chrysler Building.

- Van Cleef & Arpels often draws from lush gardens for its floral luxury watch designs.

This conceptual work requires significant time. A brand develops a new luxury collection with a clear timeline. The complexity of the luxury design dictates the schedule.

| Design Scenario | Typical Timeline |

|---|---|

| New Two-Watch Collection | 8 months |

| Simple Dial and Bracelet Swap | 1-2 months |

| Entirely New Movement | Over 8 months |

CAD MODELING AND BLUEPRINTS

Artists translate initial sketches into digital models. They use Computer-Aided Design (CAD) software for this task. CAD creates precise, three-dimensional blueprints for all luxury watches & jewelry. These digital files guide every subsequent step of production. The precision at this stage is non-negotiable for a luxury product. Engineers and artisans demand extreme accuracy. Blueprints for Swiss luxury manufacturing often require tolerances as tight as 2 to 5 microns (µm). This level of detail ensures every component fits perfectly. It is a core principle of luxury craftsmanship.

PROTOTYPING AND MATERIAL SOURCING

The prototyping phase transforms a digital blueprint into a tangible object. This step is a non-negotiable part of the process for ensuring luxury quality. It allows designers and artisans to physically assess a design’s ergonomics, aesthetics, and mechanical function before committing to full-scale production. This validation is essential for any luxury product.

RAPID PROTOTYPING AND VALIDATION

Brands first create physical models from the CAD files. Rapid prototyping techniques like 3D printing with resin or wax allow for quick creation of initial models. These models help validate the design's look and feel. For higher precision, especially for luxury watches & jewelry, manufacturers use CNC (Computer Numerical Control) machining.

| Machine Type | Typical Tolerance Range |

|---|---|

| Swiss Lathe | ±0.0002" to ±0.0005" |

| Best-Case Tolerance | ±0.0001" |

This level of precision ensures every component of a luxury piece fits perfectly.

SOURCING PRECIOUS MATERIALS

Parallel to prototyping, the sourcing of materials begins. For a luxury brand, supply chain transparency is paramount. This transparency ensures both the quality of the materials and their ethical origins. The demand for transparency from consumers continues to grow. This transparency builds trust. This transparency is a core value. This transparency is non-negotiable in the modern luxury market. This transparency defines a responsible luxury brand. This transparency must be absolute. This transparency is key. This transparency matters.

Ethical Sourcing Regulations The diamond industry follows strict rules to prevent the trade of conflict stones. The Kimberley Process Certification Scheme (KPCS) is a key part of this effort.

- It requires members to certify that rough diamond shipments are 'conflict-free'.

- The U.S. Clean Diamond Trade Act prohibits imports or exports of rough diamonds without KPCS controls.

- Importers must submit the unique Kimberley Process Certificate number for every shipment.

Sourcing extends to all precious materials. The origin of a gemstone can significantly impact its value and characteristics, a critical detail for any luxury creation.

| Country of Origin | Emerald Characteristics |

|---|---|

| Colombia | Most famous source; deep, vivid green to bluish-green color. |

| Brazil | Lighter, yellow-green; often has good transparency. |

| Zambia | Deep green with a darker tone; often more bluish-green. |

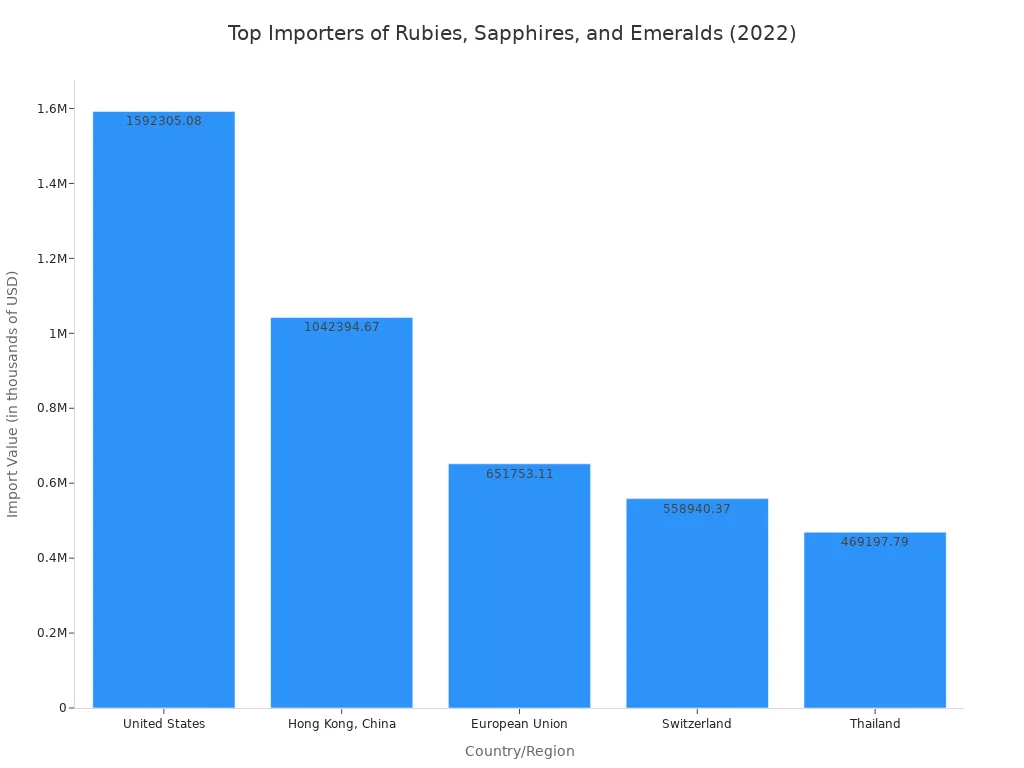

The global market for these materials is vast, with specific countries leading imports for the luxury sector.

SAMPLE PRODUCTION AND REFINEMENT

After prototyping, the journey of a luxury product moves to sample refinement. This stage bridges the gap between a validated concept and a market-ready item. Artisans create the first perfect, functional sample. This master sample becomes the gold standard for all future production. It embodies the brand's commitment to quality for every luxury piece.

CRAFTING THE MASTER SAMPLE

Creating the master sample is an act of supreme craftsmanship. Artisans use specialized tools and time-honored techniques. They transform raw materials into a flawless representation of the final luxury product. This single piece must be perfect. It sets the benchmark for the entire luxury collection. The process involves incredible attention to detail.

For luxury leather goods, like watch straps, artisans employ specific methods:

- They use saddle stitching with two needles for a balanced finish.

- They flatten stitches with a hammer and shave leather surfaces by hand.

- Artisans polish raw edges with a hot tool and apply beeswax for protection.

The creation of luxury crystal or gemstone components involves equally precise steps:

- Cutters mark a geometric grid on each piece before cutting facets by hand.

- They memorize hundreds of patterns to create brilliant designs.

- Pieces are polished to remove rough edges for a smooth feel.

- Finishing touches, like adding gold or sandblasting, create unique textures for the luxury item.

STAKEHOLDER REVIEW AND FINALIZATION

The completed master sample undergoes a rigorous review. Key stakeholders inspect every detail. This group includes designers, engineers, and brand managers. They evaluate the sample against the original design blueprints and quality standards. This step is critical for a successful luxury launch.

The master sample is the physical promise a luxury brand makes to its clients. It must be flawless. Approval at this stage gives the green light for mass production. It confirms the design is not only beautiful but also manufacturable to the highest luxury standards.

The team checks for aesthetic accuracy, material integrity, and functional performance. Any necessary adjustments are finalized at this point. This ensures the final luxury product perfectly aligns with the brand's vision. This approval is the final gate before committing to large-scale manufacturing of the luxury good.

MASS PRODUCTION AND QUALITY ASSURANCE

With an approved master sample, the production of a luxury item scales up. This phase combines advanced technology with traditional craftsmanship. It ensures every piece in a collection meets the brand's exacting standards. The goal is to replicate the master sample's perfection thousands of times over for the luxury market.

COMPONENT MANUFACTURING

The process begins by creating molds from the master sample. This is essential for casting jewelry components. Artisans follow a precise method for creating high-fidelity rubber molds.

- They apply rubber layer by layer around the master model.

- The layered rubber is then heated in a process called vulcanization.

- This forms a precise, durable mold ready for lost-wax casting.

For intricate luxury watch movements, manufacturers use highly specialized techniques. Processes like LIGA, which uses X-rays to create microstructures, and wire erosion allow for the creation of incredibly precise gears and components. Computer-guided machine tools and laser machining also produce parts with submicron accuracy. These technologies are fundamental to modern luxury watchmaking.

IMPLEMENTING RIGOROUS QC

Rigorous Quality Control (QC) is integrated into every production step. A luxury brand cannot afford any imperfections. Checkpoints are established to inspect for material purity, dimensional accuracy, and visual defects. Brands use advanced tools like X-ray Fluorescence (XRF) analyzers. These devices provide fast, non-destructive analysis of precious metals, confirming their purity in seconds.

Automation supports this quest for perfection. Computer vision AI can scan finished goods to detect minute flaws invisible to the human eye. This allows artisans to focus on detailed finishing, ensuring every luxury product is flawless.

For a luxury watch, testing is even more intense. Many Swiss timepieces seek COSC certification. This test runs for 15 days across five positions and three temperatures. A mechanical movement must maintain an accuracy between -4 and +6 seconds per day to pass. This level of scrutiny defines true luxury quality.

FINAL ASSEMBLY OF LUXURY PRODUCTS

The final assembly phase is where individual, perfected components unite to form a finished masterpiece. Master artisans meticulously bring the design to life. This stage transforms precision parts into a tangible symbol of luxury.

ARTISAN ASSEMBLY AND SETTING

Artisans dedicate immense time and skill to the assembly process. A single grand complication watch movement requires extraordinary effort. The assembly of a minute repeater, for example, can take between 200 and 300 hours of focused work. Engraving the case of a luxury watch might add another 100 hours. This painstaking labor is a hallmark of true luxury craftsmanship.

For jewelry, gemstone setters employ specialized techniques to secure each stone. The chosen method enhances both beauty and durability.

- Pavé Setting: Setters place small gems close together to create a continuous surface of sparkle. This technique uses minimal metal.

- Bezel Setting: A metal collar wraps around the gemstone. This classic style offers excellent protection for the stone.

- Prong Setting: Metal tines hold the gemstone, allowing maximum light to enter and create brilliance. It is a versatile choice for many luxury designs.

POLISHING AND FINISHING

After assembly, each piece undergoes extensive polishing and finishing. This step gives the luxury product its final character and luster. Artisans use different techniques to create specific visual effects. The finish on a luxury item is a critical design element.

| Finish Type | Characteristics | Common Usage |

|---|---|---|

| Satin (Brushed) | A soft, subtle brushed look that indicates high skill. | Sports watches, bracelets, and areas prone to scratches. |

| Polished | A shiny, mirror-like surface that reflects light easily. | Dressier watches and decorative accents. |

Another elite technique is black polishing. Artisans typically apply this mirror-like finish to small luxury watch components, like screw heads, making them appear black from certain angles.

PACKAGING AND RETAIL LOGISTICS

The final step prepares the product for the luxury retail market. The packaging is a crucial part of the overall luxury experience. Brands use premium materials like exotic woods, carbon fiber, and Alcantara linings. Features like soft-close hinges and hidden compartments for documents elevate the unboxing process.

Shipping these valuable luxury watches & jewelry requires extreme security. Standard carrier insurance is inadequate. Brands use specialized Ad Valorem insurance, which covers the item's true value. Shipments are sent in anonymous, double-boxed packaging. For maximum security in luxury retail logistics, companies use premium carriers that offer armored transport and real-time surveillance. This ensures every luxury piece arrives safely to its new owner.

The journey for luxury watches & jewelry follows five core phases.

- Design

- Prototyping

- Sample Refinement

- Mass Production

- Final Assembly

This disciplined workflow is fundamental for all luxury brands. Luxury brands use this path to maintain luxury quality. It protects the exclusivity and integrity expected in the luxury market. Mastering this process is how luxury brands build a prestigious and enduring luxury legacy. This commitment to a structured process defines a true luxury item and separates successful luxury brands from the rest. Every luxury product reflects this dedication.

FAQ

Why does luxury production take so long?

Artisans perform many steps by hand. This craftsmanship defines a luxury product. Each phase, from design to assembly, requires meticulous attention. This ensures the final luxury item meets the brand's high standards of quality.

What makes a material suitable for a luxury product?

Luxury materials possess rarity, exceptional quality, and durability. Brands select materials like high-karat gold, platinum, and flawless gemstones. The origin and ethical sourcing of these materials also add to their luxury status.

How do brands guarantee consistent quality in luxury items?

Brands implement rigorous Quality Control (QC) at every stage. They use a master sample as the benchmark for all production. This strict process ensures every single luxury piece perfectly matches the original approved design.

Is ethical sourcing a requirement for luxury brands?

Yes, it is a core expectation. Reputable luxury brands adhere to strict ethical standards like the Kimberley Process. Consumers demand transparency. This commitment protects brand integrity and defines modern luxury values.