What is Lead Time? Definition, Key Components, and Applications

One-Sentence Definition

Lead time is the total time required to complete a process from its initiation—such as placing an order—until its final result, typically the delivery of a product or service to the customer. (Merriam-Webster, Investopedia)

Detailed Explanation

In manufacturing and supply chain management, lead time measures the elapsed time from the moment a customer places an order to the moment the product is delivered. This period includes all intermediate steps: procurement of materials, production, quality checks, packaging, and shipping. Lead time is a critical metric for operational efficiency, customer satisfaction, and inventory management. Shorter lead times can improve competitiveness, reduce costs, and increase customer loyalty, while longer lead times may lead to lost sales or excess inventory.

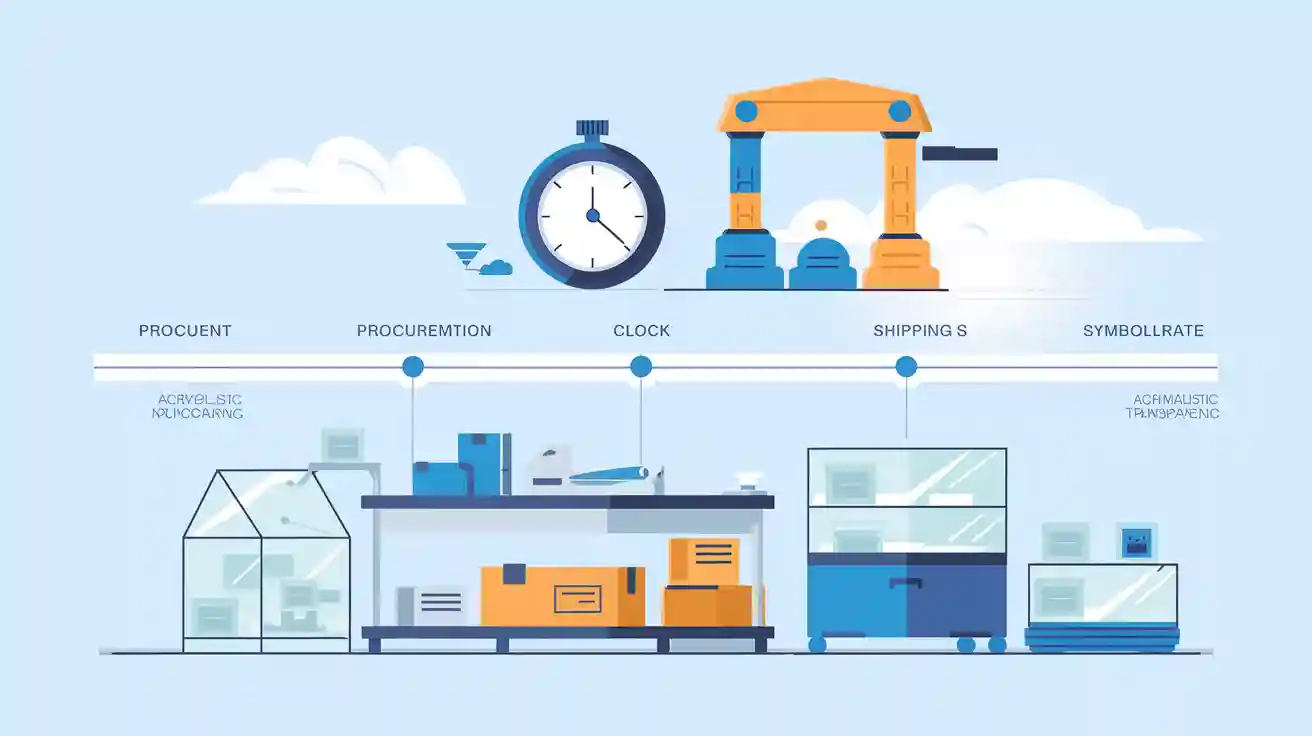

Key Components of Lead Time

Lead time is typically broken down into several stages:

- Pre-processing Time: The time spent sourcing and procuring raw materials or components needed for production.

- Processing Time: The actual time required to manufacture or assemble the product.

- Post-processing Time: The time taken for quality checks, packaging, shipping, and final delivery to the customer.

Each stage can become a bottleneck, so optimizing any part of the process can help reduce the overall lead time. Factors influencing lead time include supplier reliability, inventory levels, production efficiency, and logistics performance. (Atlassian)

Real-World Applications

Lead time is especially important in custom manufacturing, such as producing acrylic display racks or bespoke furniture. For example, a company manufacturing custom acrylic products must manage lead time across design, material sourcing, fabrication, and shipping. By implementing strategies like supplier diversification, just-in-time (JIT) inventory, and real-time process tracking, manufacturers have achieved significant lead time reductions. For instance, DisplayPeople reported a 30% reduction in lead time for a national retail rollout by optimizing their manufacturing and logistics processes (case study).

Best practices for reducing lead time include:

- Diversifying suppliers to avoid procurement delays

- Implementing lean and JIT manufacturing

- Using ERP systems for real-time process visibility

- Maintaining safety stock for critical materials

- Automating order processing and production scheduling

Related Concepts

Understanding lead time also involves distinguishing it from similar terms:

- Production Time: The time spent actually making the product.

- Delivery Time: The time from shipment to customer receipt.

- Cycle Time: The time to complete one cycle of a specific process.

- Turnaround Time: Often used in service industries, sometimes overlaps with lead time but is not identical.

- Takt Time: The rate at which products must be completed to meet customer demand.

For a visual comparison of these concepts, see this diagram from SixSigma.us.