The secret to reduce transit damage

The secret to reduce transit damage is a proactive, two-part strategy. You must implement data-driven packaging standards and validate them with rigorous drop testing. This approach moves your logistics beyond reactive damage control, where in-transit damage contributes to a $50 billion global problem and 20% of returns stem from failed packaging. Adopting new standards is an investment, not an expense.

Your 2025 Investment in Reliability:

- Logistics Standards: Enforce clear handling standards.

- Transit Testing Standards: Adopt industry testing standards.

- Packaging Standards: Define new material standards.

- Safe Delivery Standards: Guarantee arrival condition standards.

These solutions transform transit from an unpredictable cost into a controllable guarantee.

Mastering drop testing protocols

Effective transit testing protocols are your first line of defense against damage. You move from guessing to knowing. These protocols use controlled, repeatable tests to simulate the entire shipping journey. This process validates your packaging choices before a single asset leaves your facility. It is the core of proactive logistics management.

Validating packaging integrity with ISTA standards

You should build your testing protocols on the foundation of International Safe Transit Association (ISTA) standards. ISTA provides a framework to assess packaging performance. Selecting the right series is your first step. Your choice depends on your product and the known risks of your distribution channel.

| Feature | ISTA 1-Series | ISTA 2-Series | ISTA 3-Series |

|---|---|---|---|

| Test Type | Non-Simulation Integrity Tests | Partial Simulation Tests | General Simulation Tests |

| Purpose | Screens for basic strength and robustness | Combines basic and advanced test elements | Simulates a full distribution journey in a lab |

| Complexity | Basic | Intermediate | Advanced |

For most common items, these standards offer a clear path. You can use this table as a starting point for your transit testing program.

| Product Type | Recommended ISTA Test |

|---|---|

| Most Products | ISTA 2A |

| Fragile Products (e.g., electronics) | ISTA 3A |

| Very Sensitive Products (e.g., glass) | ISTA 3B or 4-Series |

Tip for Reusable Assets: 📦 Do you use reusable racks or containers, like those for automotive parts? You should adopt specific standards for them. ISTA Procedure 3H is designed for mechanically handled bulk transport containers. These standards ensure the integrity of both the product and the reusable packaging over many cycles.

Customizing the corner, edge, and flat drop

Standardized tests are a great start. True mastery comes from customizing your drop testing to mirror your specific transit environment. A drop test is not just about dropping a box. It is a calculated impact designed to find weak points. You must determine the drop height and impact surfaces based on real-world data. Consider truck bed heights, forklift handling procedures, and conveyor belt transfers.

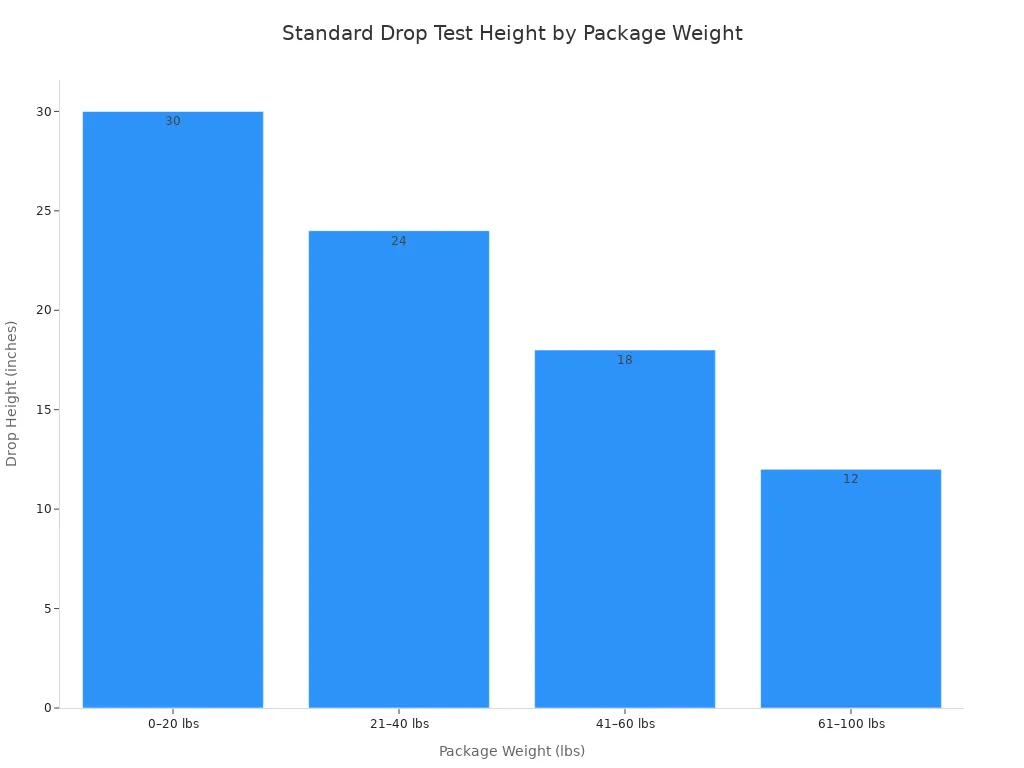

The weight of your package directly determines the drop height. Lighter packages are more likely to be tossed, so they face a higher drop. Heavier packages are dropped from lower heights to simulate a slip or mishandling during a team lift. Industry standards provide a clear guide.

| Package Weight (lbs) | Drop Height (inches) |

|---|---|

| 0–20 | 30 |

| 21–40 | 24 |

| 41–60 | 18 |

| 61–100 | 12 |

To capture precise data, you should embed sensors inside your packaging during tests. Shock data loggers use accelerometers to measure and record every impact. These devices quantify the g-force of an impact and its duration. The data shows you the exact moment and location of a potential failure. This information is critical for improving your packaging design.

Finally, do not forget about vibrations. A long truck journey or air transit involves constant, low-level stress. Vibration testing simulates this environment to ensure overall packaging quality.

- It helps you comply with global logistics standards.

- It minimizes product failures from vibrational stress.

- It validates the integrity of your packaging system against real-world conditions.

Following standards like ASTM D4169, which combines vibration with drop and compression tests, confirms your package can withstand the entire journey. This comprehensive approach to testing ensures your assets arrive with their integrity intact.

Optimizing your packaging to reduce transit damage

Rigorous transit testing reveals vulnerabilities. Optimizing your packaging is the next step to fix them. This process involves selecting the right materials and integrating technology. Your goal is to build a protective system that guarantees product quality upon arrival. Upgrading your packaging standards is a direct investment in reliability and environmental sustainability.

Innovations in cushioning and crating materials

Your choice of materials is fundamental to reduce transit damage. Modern solutions offer superior protection and advance your sustainability goals. You should evaluate these options against traditional materials like polystyrene foam.

Molded pulp is a cost-effective and sustainable alternative. It uses recycled paper and agricultural residues, which are cheaper than virgin plastic resins. One company saved $75,000 annually by switching to molded pulp for a 50-pound product. This change reduced box volume by 16.7%, saving $30,000 in shipping costs and another $45,000 on the material itself. This move also enhances environmental sustainability.

Other innovations provide targeted solutions.

- Mushroom-Based Packaging: This material is grown from mycelium and agricultural byproducts. It is fully biodegradable and compostable, supporting your sustainability initiatives.

- Honeycomb Paperboard (EcoLITE): This material is made from 100% recyclable cardboard. It serves as a strong, lightweight alternative to bubble wrap and foam for securing products during transit.

- Custom-Fabricated Crates: For high-value assets, you should use custom crates instead of standard boxes. Crates offer superior protection against shock, moisture, and tampering. They are reusable, which improves your return on investment and supports sustainable packaging practices.

You can use this table to compare key sustainable packaging options against traditional foam.

| Feature | Mushroom-Based | Molded Fiber | Styrofoam (EPS) |

|---|---|---|---|

| Renewable | Yes | Yes | Non-Renewable |

| End of Life | Biodegradable (30-90 days) | Recyclable, Compostable | Difficult to recycle |

| Durability | Durable but heavy | High protection, lightweight | Lightweight, shock absorbent |

| Cost | More expensive | Cost-effective | Cost-effective |

| Sustainability | Low resource intensity | Uses recycled materials | High energy use |

Calculating Cushioning Thickness: A Practical Guide 📝 You must use the right amount of cushioning. Too little causes damage, while too much increases costs. You can calculate the required thickness (

t) with a simple formula:t = (C * h) / G.

his the anticipated drop height in inches.Gis your product’s fragility, or G-factor.Cis the cushion factor, a value specific to each material.To apply this, you need three key pieces of data: your product’s fragility (G-factor), its weight, and the expected drop height. You can then use dynamic cushioning curves provided by material suppliers. Find the curve for your chosen material that stays below your product’s G-factor limit. This ensures your packaging provides optimal protection without overspending. This data-driven approach to packaging standards is essential for effective logistics.

Integrating smart packaging technology

Smart packaging gives you visibility and control over your shipments. It uses sensors and indicators to monitor handling conditions throughout the transit journey. This technology transforms your packaging from a passive container into an active guardian of your assets.

Simple, effective solutions include visual indicators.

- Shock Indicators: These labels, like ShockWatch®, contain a mechanism that turns bright red when a package experiences an impact beyond a set threshold. They are tamperproof and provide immediate, undeniable proof of mishandling.

- Tilt Indicators: These devices activate if a package is tilted beyond a specified angle. They are crucial for products that must remain upright. A triggered indicator helps you pinpoint liability for damage that occurred during transit.

For more detailed insights, you can embed advanced sensors into your packaging. GPS and environmental sensors collect critical data throughout the logistics chain. These devices can track:

- Real-time location

- Temperature and humidity fluctuations

- Light exposure

- Shock and vibration events

This data helps you verify that handling standards are met and provides a complete record of the journey.

Finally, you can use QR codes to streamline your logistics operations. By placing a unique QR code on each crate, you give handlers instant access to vital information. A quick scan can link to:

- Product IDs, serial numbers, or batch information.

- A centralized database for real-time inventory tracking.

- Handling instructions, assembly guides, or care guidelines.

This simple technology improves inventory accuracy, ensures proper handling, and supports your quality and sustainability goals. Integrating these smart solutions is a key part of modernizing your packaging standards to reduce transit damage and enhance your overall logistics efficiency. These sustainable packaging practices are vital for future success.

Creating a 2025 damage prevention action plan

A successful strategy requires a clear plan. You can turn your insights from testing and material selection into actionable steps. This plan will guide your team, establish new standards, and create a system of continuous improvement for your logistics operations.

Auditing your current packaging process

You must first understand your current process to improve it. A comprehensive audit gives you a baseline. It helps you identify weak points and prioritize changes. Start by defining your quality benchmarks and acceptable defect limits.

Next, you should track key performance indicators (KPIs) to measure efficiency.

- Material usage per unit

- Packaging defect rates

- Cost per unit of packaging

- Customer complaints related to packaging

Observe your production line. Note where damage occurs. Analyze rejected products to find the root cause. This data helps you focus your efforts. Your audit should verify that all packaging meets your defined standards, from carton markings to structural integrity. This systematic review is the foundation for building better logistics standards.

Audit Tip: Focus Your Efforts 🔍 Use Pareto analysis on your audit data. This method helps you identify the 20% of issues causing 80% of your problems. It ensures you apply resources to the most critical areas first, creating impactful solutions.

Implementing team training and accountability

Your plan is only as strong as the team executing it. You need to implement training that reinforces your new standards. Your training program should be hands-on. Demonstrate correct packing techniques, from wrapping and cushioning to sealing and labeling. Use visual aids and real-world examples to explain your quality standards.

You must also train your team on smart technology. Explain how to use and interpret shock and tilt indicators. This knowledge empowers them to identify mishandling within the supply chain logistics. It also builds accountability. To support this, you need a clear system for documenting incidents. Use standardized forms to report damage promptly and objectively. This practice helps you track patterns, address root causes, and continuously refine your packaging standards. Effective training and clear accountability are how you reduce transit damage and enforce your new handling standards. This approach ensures your logistics team understands and follows the new standards.

The most effective way to reduce transit damage is by combining customized transit testing with optimized, modern packaging standards. This proactive system transforms transit from an unpredictable cost center into a controllable variable. Adopting these logistics standards boosts operational efficiency. It also builds client confidence, as one in three customers may leave after a single bad experience. Your new handling standards and quality standards ensure your logistics operations meet customer expectations. These transit standards are your new guarantee.

Your Next Step 🚀 Begin your journey to zero-damage transit this week. Select one high-value, frequently damaged asset. Audit its packaging and handling process from start to finish to enforce your new standards.

FAQ

How do I start if my budget is limited?

You can start small. Audit one high-value item. This focused approach reveals key issues. It helps you find cost-effective solutions for your logistics process without a large initial investment.

Why is sustainability so important in packaging?

Sustainability reduces waste and often lowers costs. Modern materials improve your brand image. Embracing sustainability in packaging shows your commitment to environmental responsibility. This focus on sustainability is key for modern business.

What is the most critical part of reducing transit damage?

The most critical part is data. You must test your packaging against real-world transit conditions. This data allows you to create customized solutions that protect your specific assets effectively.

How does this improve my overall logistics?

This strategy makes your shipping predictable. It reduces returns and replacement costs. Your improved logistics process ensures products arrive safely, which boosts customer trust and protects your bottom line during transit.