5 Tips to Pick a Custom Acrylic Display Manufacturer

Your beauty brand needs to capture customer attention in stores. You face a big challenge: finding a partner for high-quality, bespoke displays. This partner must deliver on time and within your budget.

This guide for 2026 empowers you to vet a custom acrylic display manufacturer on key factors. Your goal is to choose a reliable partner. A great partner will elevate your brand's in-store presence and help you succeed. Choosing the right custom acrylic display manufacturer is a critical step for your brand's retail strategy.

Tip 1: Vet Your Custom Acrylic Display Manufacturer

The first step is to confirm a manufacturer's expertise. You need to see proof of their experience and the quality of their work. A great partner will have a strong track record in your specific industry.

Review Their Beauty Industry Portfolio

A general portfolio is not enough. You need a partner who understands the beauty market. Look at their past projects. Do they have experience in the beauty world? A skilled custom acrylic display manufacturer will proudly showcase their work with brands in specific retail environments.

Ask your potential partner for examples of displays they created for:

Makeup stores like Ulta or Sephora

Perfume counters in department stores

Specialty nail salons

For instance, brands like e.l.f. Cosmetics and Kneipp have used custom acrylic displays to stand out in Ulta stores. Seeing similar projects shows the manufacturer can meet the high standards of top beauty retailers.

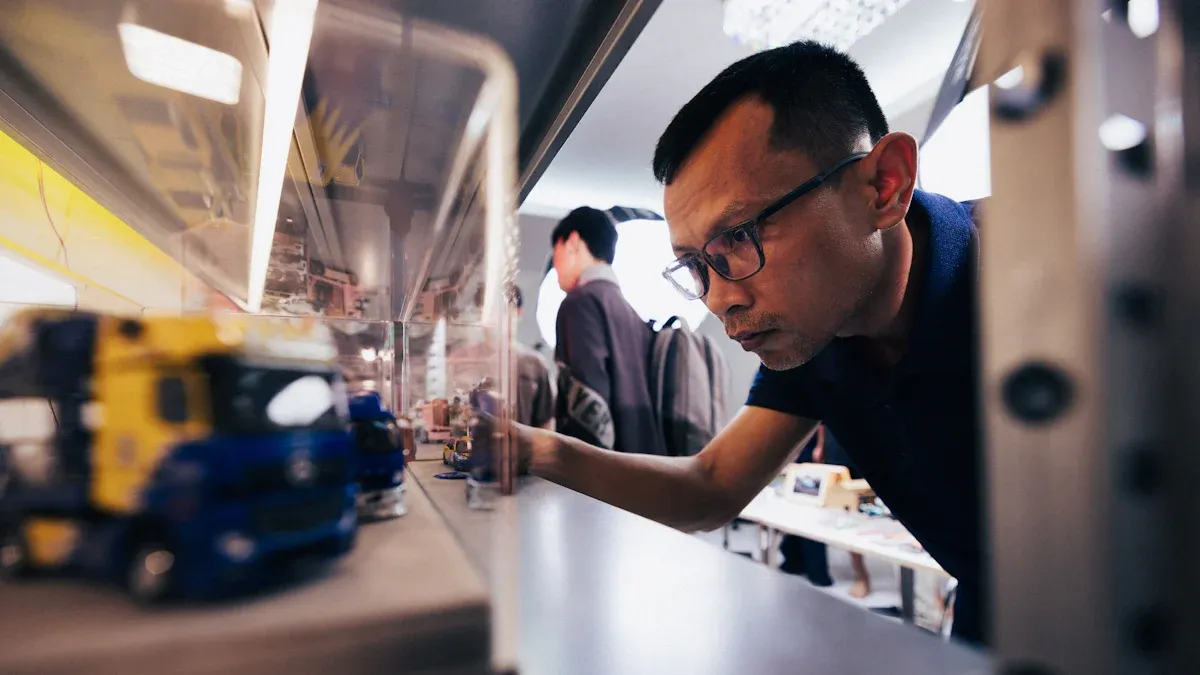

Request Physical Samples for Quality

Pictures can be deceiving. You must hold a physical sample to truly judge the quality. This step helps you assess the craftsmanship, from the smoothness of the finish to the precision of the cuts. A sample reveals the true look and feel of the final product.

Note: Always ask for a sample made from "high-clear, 100% new raw acrylic material." This premium material ensures your displays are durable, resist yellowing from UV light, and have a crystal-clear look that makes your products shine.

A quality sample proves the manufacturer can deliver a polished, professional display. It protects your investment and ensures your brand is presented perfectly in every store.

Tip 2: Clarify MOQ, Pricing & Costs

A clear understanding of all costs is essential for a smooth project. You need to look beyond the per-unit price to see the full financial picture. This protects your budget and prevents surprises down the line.

Understand Minimum Order Quantity (MOQ)

The Minimum Order Quantity (MOQ) is the smallest number of units a manufacturer will produce in one run. This number varies significantly between suppliers. For example, some manufacturers in China may set their MOQ at 50 units, while a US-based partner might require a minimum of 12 units. Ask about the MOQ early to ensure a manufacturer is a good fit for your brand's needs. Some partners offer competitive MOQs starting from 50 units, which is great for smaller or test rollouts.

Request a Detailed Price Quote

Pricing for custom displays is not one-size-fits-all. For 2026, you should get updated pricing that reflects current material and labor costs. The price per unit often depends on order volume. Larger orders allow manufacturers to buy raw materials in bulk and optimize production, which lowers your cost.

Pro Tip: Always ask for a tiered pricing quote. This shows you how the per-unit cost decreases as your order quantity increases.

The complexity of your design also affects the price. Custom shapes, vibrant UV-printed colors, and multi-tiered structures will cost more than a simple, clear easel. A detailed quote helps you understand these variables.

Uncover All Potential Costs

The price on your quote is rarely the final price. You must ask about other potential charges to avoid budget overruns. Be sure to discuss these specific costs:

Tooling Fees: Are there one-time costs for creating molds or setting up machinery for your custom design?

Specialized Packaging: Does your display require special packaging to prevent damage? This is crucial but can add to the cost.

Freight Charges: Shipping can be a major expense, especially for international orders. Ask how freight is calculated. Carriers often use volumetric weight, which can make bulky, lightweight items expensive to ship. Discussing options like sea freight or disassembled shipping can help you save money.

Tip 3: Verify Production & Shipping Timelines

Your product launch date is fixed. You need your displays to arrive on time. A delay can disrupt your entire marketing campaign. You must get clear timelines for both production and shipping from the start.

Confirm the Full Production Lead Time

Lead time is the total time from when you place your order until it's ready to ship. This timeline depends heavily on the manufacturing process your partner uses. Complex designs or methods like injection molding require creating a custom mold, which can take weeks.

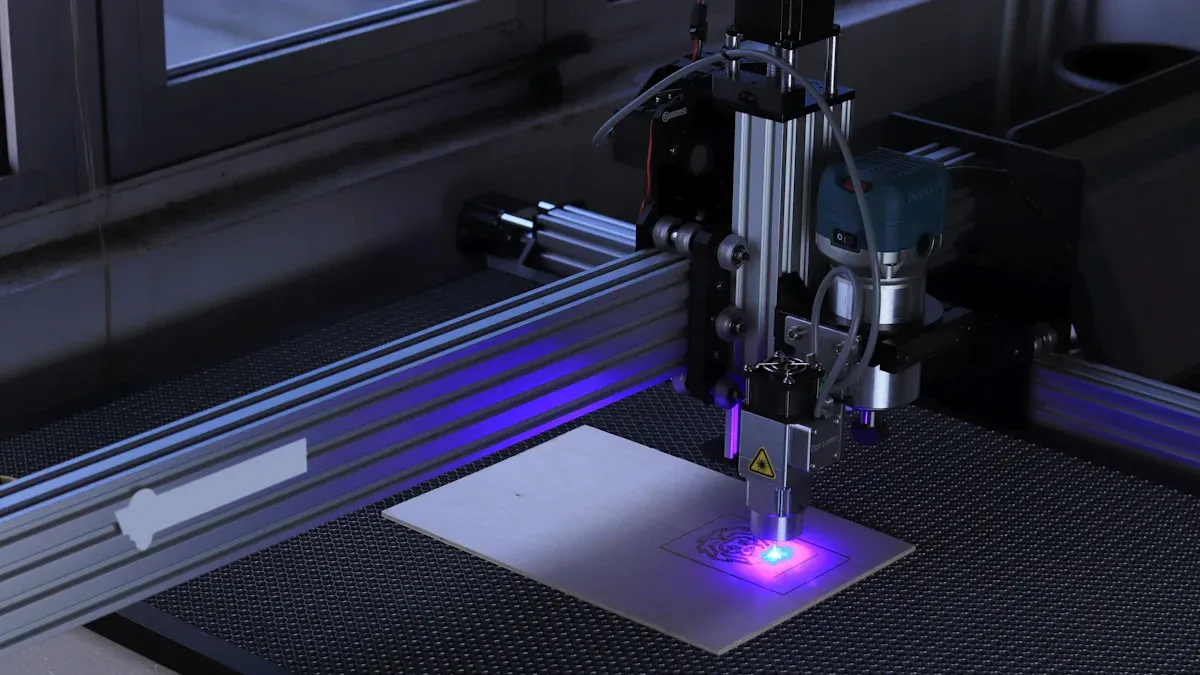

Ask your manufacturer about their production methods. Processes like 3D printing and laser cutting are much faster for initial samples because they don't require molds.

Understanding the process helps you get a realistic timeline. Compare these common methods:

Process | Initial Workpiece Timeline |

|---|---|

Injection Molding | Several weeks to months |

Laser Sintering (3D Printing) | Within 48 hours |

A faster process for prototypes allows you to make design changes quickly and move to full production sooner.

Discuss Shipping and Delivery Logistics

Once your displays are built, how do you get them to your stores safely and on budget? Shipping is a major step with its own timeline and costs. You have two main options: air freight and sea freight. Your choice depends on your budget and deadline.

Factor | Air Freight | Sea Freight |

|---|---|---|

Transit Time | Faster | 25 to 45 days |

Cost | Costly | Most cost-effective |

Volume Suitability | Smaller volumes | Large volumes |

Pro Tip: A global watch brand saved $8,200 on a launch by using a split shipping strategy. They sent urgent samples by air courier and the main rollout by sea. This smart plan got their displays to 20 stores on time and under budget.

Finally, discuss packaging. While acrylic is a durable material, it needs proper protection. Ask your partner how they package displays. Good packaging uses:

Custom compartments to stop items from moving.

Sturdy outer boxes to protect against impacts during transit.

Tip 4: Assess Design & Engineering Support

A great idea for a display is just the beginning. You need a partner who can turn your vision into a functional and affordable product. The manufacturer's design and engineering support is key to making this happen. They help you avoid costly mistakes and ensure the final display is both beautiful and practical.

Evaluate In-House Design Capabilities

An experienced in-house design team does more than just draw your display. They provide value engineering, which means they find ways to improve function and reduce costs without sacrificing quality. A skilled team can guide your project to be more efficient.

Ask a potential partner how their design team can help you save money. For example, they can:

Design around standard material sizes. Using standard acrylic sheet dimensions can significantly lower material costs. One project saved 21% on panel price by making a small adjustment to fit a standard size.

Suggest cost-effective shapes. They can configure panel shapes, sizes, and thicknesses to fit your budget.

Identify potential cost increases. They will warn you if custom molds or special bonding processes are needed, as these add to the final price.

Review the Prototyping Process

A prototype is a physical sample of your design. It is your chance to see, touch, and test the display before you commit to a full production run. This step is crucial for catching any design flaws early. You should ask about the manufacturer's prototyping process, paying close attention to speed.

A fast prototyping process keeps your project on schedule. Some partners can create a prototype in just a few days. For example, you might get a sample in 3-5 days, or even as fast as 48 hours for simpler panel designs.

A quick turnaround on your prototype allows you to approve the design quickly. This lets you move forward to full production without long delays, ensuring you meet your launch deadline.

Tip 5: Gauge Communication & Service

A great product is not enough. You need a partner who communicates well and provides excellent service. Strong communication prevents misunderstandings and keeps your project on track from start to finish.

Test Responsiveness and Clarity

Pay close attention to how a potential partner answers your questions. Are their responses fast and clear? Good communication is a sign of a professional and reliable team. You should make notes of any communication issues before you commit to an order.

Be aware of these communication red flags 🚩:

They give vague answers to your important questions.

They only send a product catalog and do not share past projects.

You have trouble understanding them, which could create future problems.

A lack of transparency is a major warning sign. A trustworthy partner will be open about their processes. They should provide clear documents and explain their quality plan. If a manufacturer is not open with you, it may be best to look elsewhere.

Inquire About Quality Control

You need to know that every display will meet your standards. Ask about the manufacturer's quality control (QC) process. A serious partner has a multi-step plan to check quality. They inspect raw materials, check products during production, and perform a final assessment.

Look for official certifications that prove a commitment to quality. These documents show that an independent party has verified their systems. Key certifications include:

ISO 9001: This confirms the manufacturer has a strong quality management system. It covers everything from material selection to final inspection.

BSCI: This shows the company follows fair labor rules and has a safe workplace.

Other important certificates like REACH and RoHS show that the products meet European standards for environmental safety and are free from specific hazardous materials. This ensures your displays are safe for stores and customers.

Choosing a partner is a strategic decision beyond just price. Your success depends on finding a manufacturer who aligns with your brand's goals.

Remember these five tips:

Vet their specific beauty industry experience.

Clarify all costs and quantities for 2026.

Confirm production and shipping timelines.

Assess their in-house design support.

Gauge their communication and service.

Apply this framework to secure a custom acrylic display manufacturer. A great partner will bring your vision to life and prepare you for future retail trends like modular designs and interactive experiences.

FAQ

What is the typical lead time for custom acrylic displays?

Lead times vary by project complexity. Simple orders can ship in as few as 15 days, while more complex designs require longer. You should always confirm the specific timeline with your chosen manufacturer to meet your launch date.

How can I reduce the cost of my custom displays?

You can lower costs by simplifying your design and ordering a larger quantity. Ask your partner to design around standard material sizes. This simple change reduces material waste and saves you money on the final project.

Why should I choose 100% new raw acrylic?

You should choose 100% new raw acrylic for its premium quality. It offers superior clarity to showcase your products beautifully. This material also resists yellowing from UV light, which keeps your displays looking new for longer.

What information should I provide for an accurate quote?

Provide your manufacturer with key details for an accurate quote. You will need to share:

Your design files or drawings

The total order quantity

Your target delivery date

Any special printing or finishing needs