How to Brief a Manufacturer for Collectibles

You want the perfect acrylic display for your prized collectibles. The global collectibles market is growing at 5.43% annually, making a quality display essential. To get your custom displays without costly errors, you must brief a manufacturer with a clear plan.

The Solution: A "Technical Specification Sheet."

This document details your design for the acrylic display case. It is the best tool for all your display cases. It ensures your acrylic cases for your collectibles, display cases, display cases, display cases, display cases, display cases, display cases, and display cases are perfect.

How to Brief a Manufacturer: The First Steps

Your journey to the perfect custom display begins with clear, foundational details. Before you can brief a manufacturer, you must define the core requirements of your project. These first steps build the entire foundation for your technical sheet and prevent costly misunderstandings later. A strong start ensures your final products meet your exact vision.

Defining Your Collectibles: Cards, Figures, Sneakers

You must first identify what you are displaying. Different collectibles have unique needs for their cases. A display for a signed jersey is very different from a case for a delicate figurine. Your manufacturer needs to know the item to suggest the best materials and construction options.

Common types of collectibles requiring custom display cases for collectibles include:

Trading Cards and Comic Books

Action Figures and Statues

Sports Memorabilia (balls, bats, jerseys)

Sneakers and Handbags

Scale Models (cars, ships, planes)

Coins and Stamps

Each of these products requires a unique approach. For example, paper-based collectibles like trading cards need UV protection to prevent fading. A heavy statue needs a sturdy base for support. Clearly stating the item you want to display is the essential first step. These details help define the purpose of your cases.

Specifying Exact Dimensions

Accuracy is critical for a perfect fit. You must provide precise measurements for your collectibles. Do not guess or use online listings. Standard sizes can vary, and a few millimeters of difference can ruin the fit of your custom cases.

For example, most trading cards like Pokémon or Magic: The Gathering are a standard 2.5 x 3.5 inches. Many popular action figures, such as the Star Wars Black Series or Marvel Legends, are in the "6-inch scale," but their actual height and width vary based on the character's pose and accessories. These standard sizes are a good starting point, but they are not a substitute for exact measurements.

Pro Tip: Always measure your actual item with a ruler or calipers. Provide the manufacturer with the internal dimensions your display needs in a simple

Length x Width x Heightformat. This measurement tells the manufacturer the exact open space you require inside the display.

Personal vs. Point-of-Purchase Displays

Next, define the purpose of your display. Are you creating a personal display for your home, or are you designing retail displays for a store? The function of the display cases for collectibles dramatically changes the design requirements.

Personal Displays: These cases prioritize long-term protection and aesthetic appeal. The main goal is to showcase your collectibles safely. You might focus on features like UV-filtering acrylic and museum-quality finishing.

Retail Displays: A commercial display must be durable, eye-catching, and functional for a business environment. If you are creating products for retail, you need to think like a business. Consider these questions when you brief a manufacturer for your retail displays:

Branding: Do you need your logo or other graphics printed on the displays?

Durability: Will customers interact with the display? It may need stronger materials or locking mechanisms.

Quantity: How many units do you need? Manufacturers have minimum order quantities (MOQ) you must meet.

Shipping: How will the products ship to your retail stores or customers? This affects packaging design and cost.

Defining whether your project is for personal or retail use helps the manufacturer recommend the right materials, features, and production options for your specific needs. A point-of-purchase display has very different demands than a simple case for a personal collection of collectibles. This information is vital for an accurate quote and successful production of your display cases for collectibles.

Designing Custom Display Cases for Collectibles

Once you define your project's scope, you must translate your vision into a concrete design. This stage is where your ideas become a blueprint for the manufacturer. Clear visual instructions are essential for creating the perfect display cases for collectibles, whether for personal protection or for retail visual merchandising. Your design choices impact the final product's durability, visibility, and aesthetic.

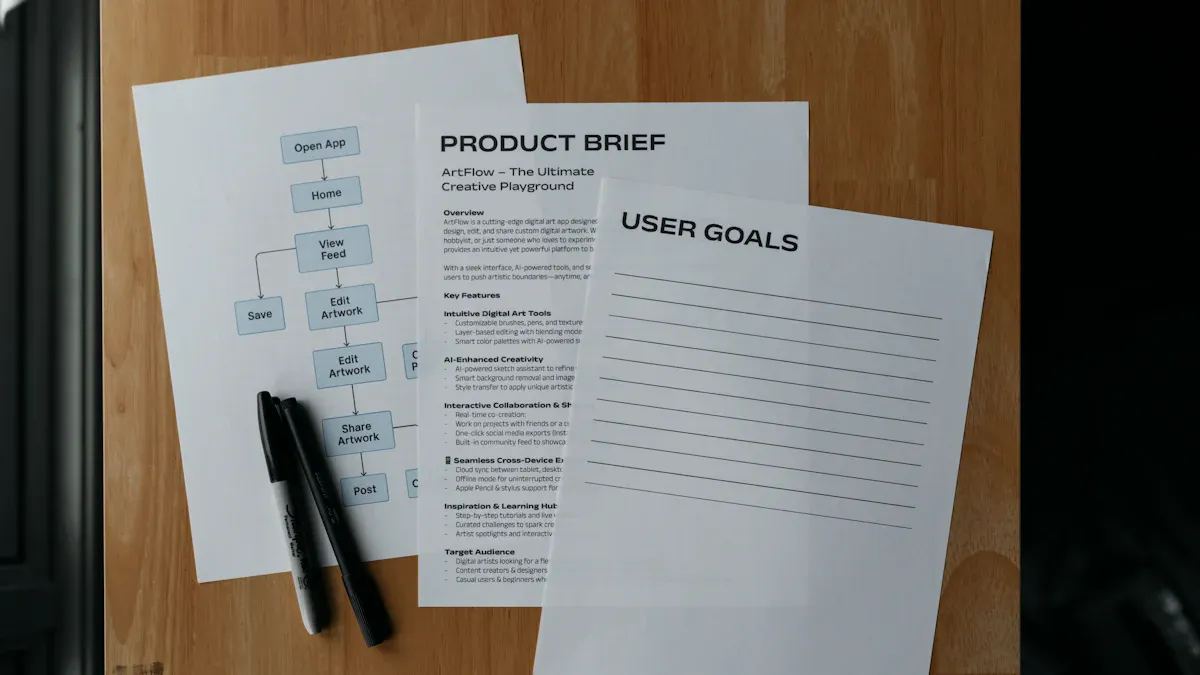

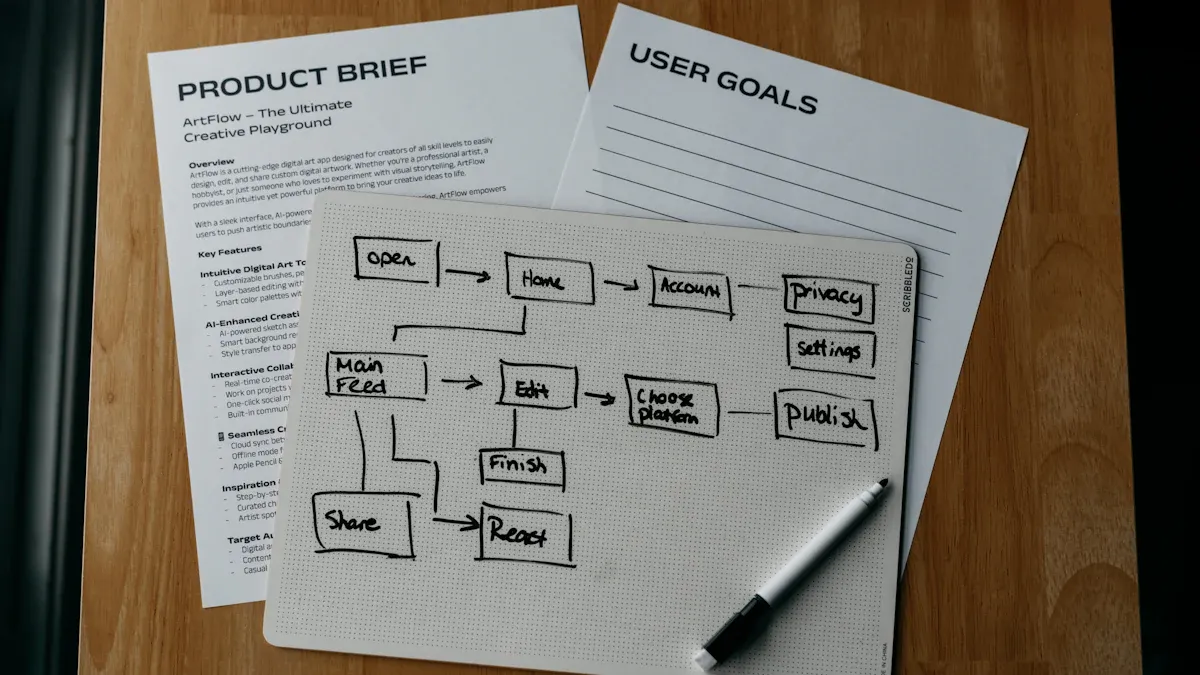

Providing Mockups and Technical Drawings

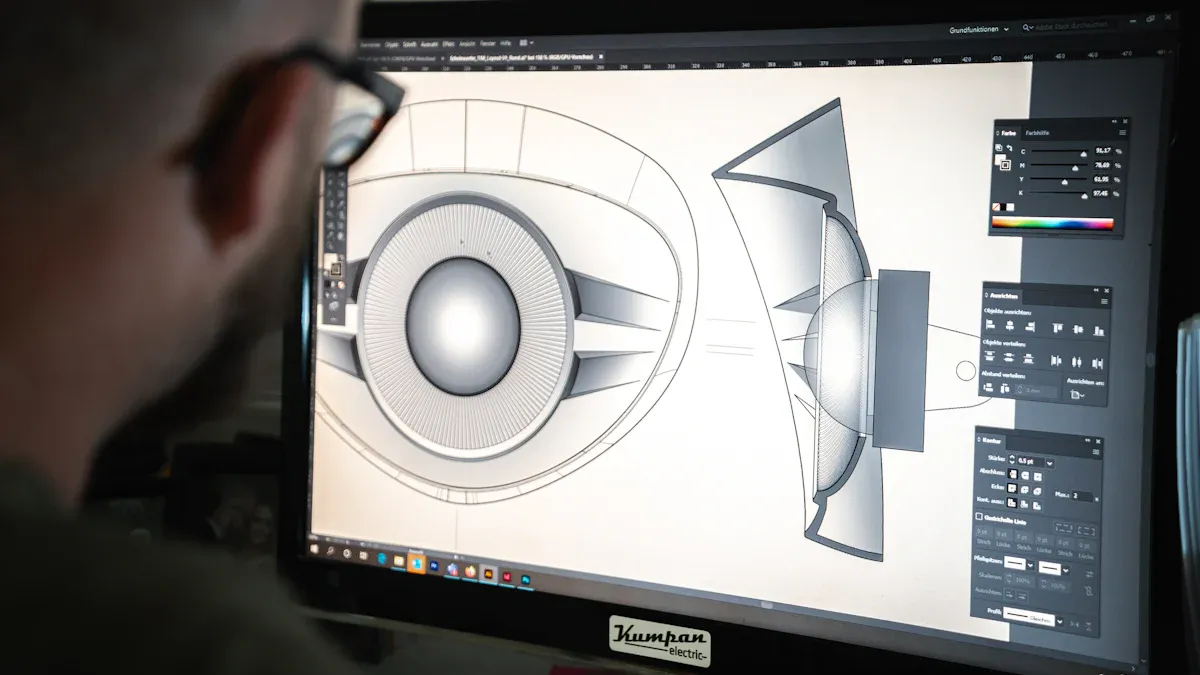

A picture is worth a thousand words, especially in manufacturing. You should provide visual aids to show the manufacturer exactly what you want. You can create these using various software options.

Free Tools: Programs like Blender or SketchUp Free are great for creating 3D mockups of your display cases. These help visualize the final products.

Paid Tools: Professional software like SOLIDWORKS allows for precision engineering, which is ideal for complex designs.

For manufacturing, you need more than a simple picture. You need a technical drawing. This document includes precise dimensions, material thickness, and special features. For example, if you need adjustable plates for different collectibles, you must specify this in your drawing. Manufacturers prefer industry-standard file formats for these drawings.

Pro Tip: Always export your final design in a neutral CAD format. STEP files are the most widely accepted for 3D models, while IGES is another common option. This ensures compatibility with the manufacturer's software.

Specifying Logos and Print Finishes

Branding transforms a simple acrylic display case into a professional product. This is especially important for retail displays and point-of-purchase displays, where brand recognition drives sales. If you need a logo on your cases, you must provide the correct file type. Logos should always be in a vector format (like SVG or PDF). Vector files can be scaled to any size without losing quality, unlike raster files (like JPG or PNG) which become blurry.

You also need to specify the print finish for your acrylic displays. Different options offer different styles and levels of durability. Common choices for an acrylic display case include:

UV Printing: This method prints full-color graphics directly onto the acrylic surface. It is excellent for vibrant, eye-catching visual merchandising.

Laser Engraving: This technique etches your design into the acrylic, creating a subtle, high-end look. It offers great protection for the design itself.

Your choice affects the cost and appearance of your products. Discussing these options with your manufacturer helps you balance your budget with your visual merchandising goals for your retail products and collectibles cases. These details ensure your final display cases for collectibles have the right visibility and styles for your needs.

Specifying Materials and Construction

Your design is ready. Now you must choose the right materials and construction methods. These choices directly impact the durability, appearance, and cost of your final products. A clear specification ensures your manufacturer builds your display cases for collectibles to the high standard your collectibles deserve. This section guides you through selecting the best acrylic and assembly options for your project.

Choosing the Right Acrylic

The term "acrylic" covers several types of material. The type of acrylic you choose affects the clarity, durability, and price of your cases. You must specify the exact type, thickness, and any special properties like UV protection. This information is vital for creating high-quality displays.

First, you need to understand the two main types of acrylic sheets: cast and extruded. Cast acrylic is generally higher quality but more expensive. Extruded acrylic is a cost-effective option that works well for many projects. Your choice depends on your budget and the needs of your display.

Property | Cast Acrylic | Extruded Acrylic |

|---|---|---|

Scratch Resistance | More scratch resistant | Less scratch resistant |

Optical Clarity | Higher optical clarity | Generally lower optical clarity |

Thickness Tolerance | Varies more (+/- 15%) | More consistent (+/- 10%) |

Fabrication | Cleaner cutting edge | Easier to bend with heat |

Colors | Many color options | More limited color selection |

Cost | More expensive | More cost effective |

Next, you must specify the thickness of the acrylic. Thickness adds strength and a premium feel to your display. A thin acrylic might feel cheap for a heavy item, while a very thick acrylic might be too expensive for small cases. For example, a 1/4" (6 mm) sheet is great for standard display cases, while a 1" (25 mm) sheet offers a high-end look for luxury products.

Pro Tip: For personal displays at home, a thickness of 1/4" to 3/8" offers great visibility and a sturdy feel. For retail displays that hold heavier products, consider 1/2" to 1" thick acrylic for added strength and a premium appearance.

Finally, consider protection for your valuable collectibles. Sunlight and even indoor lighting can cause colors to fade over time. UV-resistant acrylic filters out these harmful rays. This is a crucial feature for preserving the value and appearance of your items. Using UV-filtering acrylic offers several key benefits for your display cases for collectibles.

Prevents Fading: It shields your collectibles from sunlight, keeping colors bright and preventing discoloration.

Preserves Value: Items in mint condition are worth more. UV protection helps maintain the market value of your collectibles.

Maintains Integrity: UV light can make materials like paper brittle. This special acrylic helps prevent physical damage.

Enhances Appearance: The acrylic provides excellent visibility while blocking harmful rays, making your display both safe and beautiful.

Detailing Assembly and Special Features

How will your acrylic display case be put together? You must communicate the assembly method to your manufacturer. This detail affects the final look, strength, and shipping cost of your products. You also need to decide if you want any special features to make your displays stand out.

You have several assembly options for your cases. Some methods create a permanent bond, while others allow for disassembly.

Solvent Welding: This method uses a chemical to fuse the acrylic panels together. It creates a very strong, permanent, and clean-looking seam. This is ideal for high-quality displays where you want maximum visibility.

Screws: Using screws is a common way to join panels. This method is not permanent, which can be useful. The manufacturer will use special screws designed for plastics to prevent cracking.

Snap-Fits or Tabs: For high-volume orders, you can design cases with interlocking tabs. The parts simply snap together. This is a low-cost assembly method often used for mass-produced products.

You also need to decide how you want to receive your finished cases. This choice impacts shipping costs and your own workload.

Feature | Fully Assembled | |

|---|---|---|

Pros | Lower shipping costs and often faster lead times. | Ready to use immediately. Stronger construction done by professionals. |

Cons | You must build the cases yourself, which takes time. | Higher shipping costs and may have longer lead times. |

Finally, think about adding special features to improve the function and styles of your display. These details can turn a simple box into a premium experience for your collectibles. Popular options include:

LED Lighting: Lights make your collectibles pop and draw attention, perfect for a centerpiece display.

Magnetic Lids: These provide a clean, seamless closure for your cases with easy access.

Mirrored Backs: A mirrored panel adds depth and provides a 360-degree view of your item.

Locks: For valuable items or retail displays, locks add a necessary layer of security and protection.

Clearly defining these construction details, assembly options, and special features gives your manufacturer the complete blueprint for your project. This ensures the final products match your vision in both quality and style.

Finalizing Logistics and Requesting a Quote

You have your design and materials. Now you must finalize the logistics to get an accurate quote. This final step involves communicating your quantity, timeline, and shipping needs. Clear instructions here prevent surprise costs and ensure your products arrive safely and on time. This is the last part of your plan when you brief a manufacturer.

Stating Quantity, Timeline, and Budget

Your manufacturer needs three key numbers to create a quote: how many, how soon, and how much. Your order quantity directly impacts the per-unit price. Larger orders benefit from economies of scale, as fixed setup costs are spread across more products. This makes each display cheaper. Some manufacturers have a Minimum Order Quantity (MOQ) of 100 units, while others have no minimum at all. Knowing your quantity helps you find the right partner for your project. This is important for both personal and retail products.

Your timeline also affects your options. You must state your ideal delivery date.

Domestic Production: Generally offers faster turnaround, around 60-90 days.

Overseas Production: Often takes longer, from 90-120 days, due to shipping and customs.

Finally, provide a budget range. This helps the manufacturer suggest the best options for your price point. You can ask for quotes using different Incoterms to understand costs. For example, an EXW (Ex Works) price is just for the products at the factory, while a FOB (Free On Board) price includes getting the products onto a ship. These terms clarify who pays for each step of the shipping process for your display cases for collectibles. This information is vital for retail visual merchandising and finding the right marketplaces for your products.

Defining Packaging and Shipping Needs

How will your acrylic displays get to you? You must define your packaging and shipping requirements. This protects your investment and ensures your collectibles cases arrive in perfect condition. For fragile acrylic products, specify the need for protective materials.

Packaging Tip: Request that each display is wrapped in materials like bubble wrap or LDPE foam inside a sturdy cardboard box. This prevents scratches and breakage during transit.

Next, you must decide on a shipping method. Your choice depends on your budget and timeline.

Shipping Method | Speed | Cost | Best For |

|---|---|---|---|

Sea Freight | Slower (20-45 days) | Lower | Large, heavy orders; not time-sensitive |

Air Freight | Faster (1-5 days) | Higher | Urgent orders; smaller, high-value items |

Clearly stating your shipping preference helps the manufacturer provide an accurate quote. You can also ask for a DDP (Delivered Duty Paid) price. This all-in-one option includes all shipping, customs, and delivery costs to your door. This makes it one of the simplest options when figuring out where to purchase display cases. Defining these logistics ensures your custom acrylic cases for your collectibles are produced and delivered smoothly, ready for your visual merchandising displays or personal collection. This is the final step to brief a manufacturer before you get your beautiful new display cases.

A detailed brief is your most important tool for a successful project. This preparation saves you time and money on your display cases. You can avoid disappointment with your final display cases. Your plan ensures you get the perfect display cases for your collectibles. These cases will create a beautiful display. Your display cases will protect your collectibles. This display is an investment.

Use this guide to confidently contact a manufacturer. You can get an accurate quote for your custom display cases. Get the perfect display cases for your display.

FAQ

What is a Minimum Order Quantity (MOQ)?

An MOQ is the smallest order a manufacturer will accept. You must meet this number for your display project. A low MOQ is good for a personal display. A higher MOQ often lowers the cost for each display, which is better for a large retail display order.

Can I get a sample before placing a full order?

Yes, you should always request a sample display. This sample lets you check the quality of the display before production. It ensures your final display cases meet your standards. This step is vital for a successful retail display. A good sample confirms the quality of your display cases.

How do I protect my unique display design?

You can ask the manufacturer to sign a Non-Disclosure Agreement (NDA). This legal document protects your idea for the display. It prevents them from sharing your unique display design with others. This is important for a new retail display or custom display cases for a special collection.

What file format is best for my display design?

You should provide a vector file for your display logo. Use formats like

.SVGor.STEPfile is best. These files ensure your manufacturer can create an accurate display from your design for all your display cases.