How to Audit a Factory Your ISO 9001 OEM

Auditing an ISO 9001 OEM for museum-grade fixtures goes beyond a simple certificate check. This guide on how to audit a factory equips you to systematically verify quality, ethics, and specialized skills. A successful audit uses a three-phase framework:

- Document Review

- On-Site Process Inspection

- Capability Assessment

Note: This practical, step-by-step approach helps you confirm your partner truly meets your high standards.

Phase 1: Pre-Audit Document Review

Your audit begins before you ever step foot in the factory. This initial document review helps you verify claims and understand the OEM's quality framework. A thorough review sets the foundation for an effective on-site inspection.

Verify ISO 9001 and WCA Certifications

First, do not simply accept a PDF of an ISO 9001 certificate. You must verify its authenticity.

- Use the International Accreditation Forum’s global database, IAF CertSearch, to confirm the certificate's status.

- Contact the issuing certification body directly for validation.

For social compliance, review the Workplace Conditions Assessment (WCA) report.

Tip: Look for an "Achievement Award" status. This indicates the factory meets high ethical standards. Scrutinize the report for any non-compliance issues, especially in labor, health, and safety.

Review the Quality Management System (QMS)

The QMS is the factory’s rulebook for quality. Request the core QMS documents to understand their processes. A robust system includes:

- Quality Policy: The company's top-level commitment to quality.

- Procedures: Documents explaining how key processes are performed.

- Work Instructions: Detailed, step-by-step guides for specific tasks.

- Records: Evidence that activities were completed as required.

A strong QMS also has clear systems for document control, risk management, and employee training.

Analyze Corrective Action (CAPA) Records

CAPA records show how a factory solves problems. When you analyze these documents, you are learning how to audit a factory's real-world performance. Look for evidence that they effectively handle issues like non-conforming raw materials or customer complaints. A common red flag is when a factory records a complaint but fails to document a complete corrective action.

Check Internal Audit Reports

Internal audit reports are the factory's self-evaluations. These documents reveal how well the QMS is followed day-to-day. A good report should clearly state its:

- Audit objective and scope

- Audit criteria (e.g., ISO 9001)

- Audit findings and evidence

- Audit conclusions on QMS effectiveness

Reviewing these reports shows you if the OEM is committed to continuous improvement or just maintaining a paper-based system.

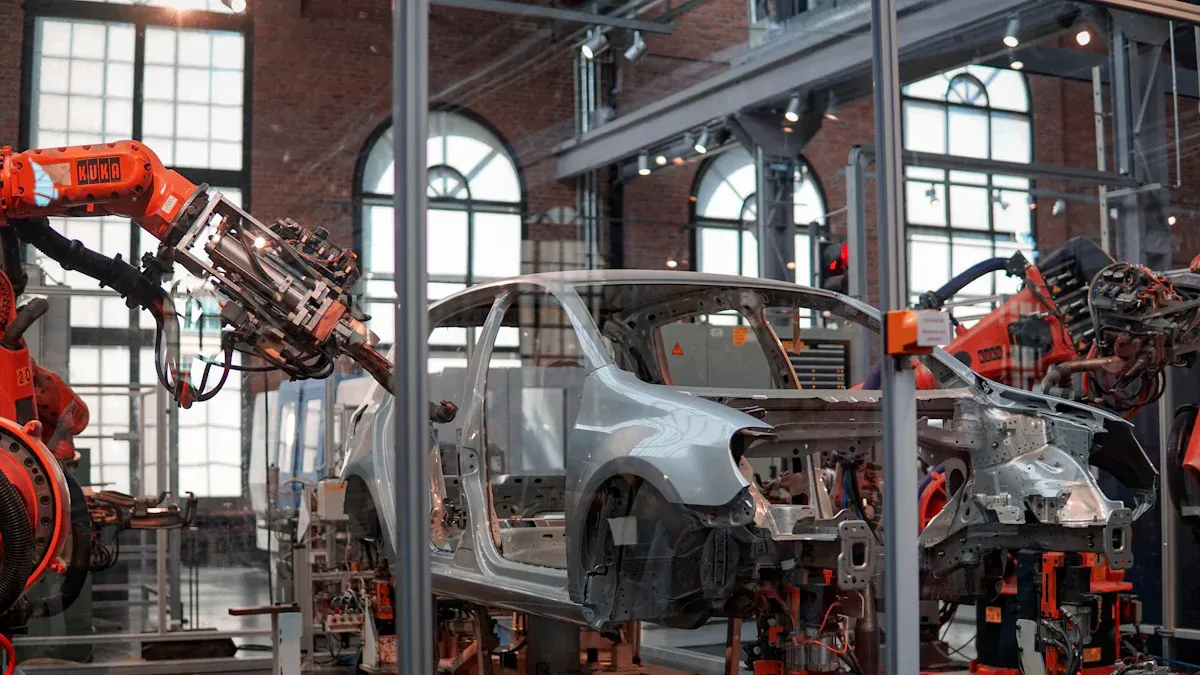

Phase 2: How to Audit a Factory's On-Site Processes

After reviewing the documents, you will visit the factory. A typical on-site manufacturing audit takes one to two days. Your main goal is to find evidence that the Quality Management System (QMS) is actively used, not just documented. A factory that doesn't apply its own rules for processes like Corrective Actions (CAPAs) is a major red flag. This phase of learning how to audit a factory is about observation and verification.

Tip: 💡 Use a digital checklist on a tablet or phone. This makes the audit more efficient and helps you organize photos, notes, and findings in real-time.

Inspect Raw Material Control

Your inspection begins where the factory's process begins: with raw materials. You need to see how the OEM controls the quality of incoming materials like acrylic, wood, and stainless steel. A strong system includes:

- Unique Identifiers: The factory should assign a unique ID, like a barcode or QR code, to every batch of raw material. This allows for full traceability from the supplier to the finished product.

- Clear Standards: The factory must have clear, documented specifications for all materials. You should see inspectors verifying incoming shipments against these standards.

- Proper Storage: Materials for museum fixtures require special care. For example, wood and wood composites should be sealed with barrier coatings and stored in a way that allows sealants to cure for at least three weeks. Acrylic sheets must be stored to protect them from scratches.

- Employee Training: Workers in the receiving and storage areas must be trained on these traceability and handling standards to maintain quality.

Assess Fabrication and Machining

Next, you will walk the production floor to observe fabrication processes. You are looking for a disciplined, controlled environment. A key part of how to audit a factory is to verify that quality checks are built into the workflow, not just done at the end.

Look for evidence of a clear quality plan for each project. This includes:

- Material Verification: Before production starts, workers should confirm they are using the correct material type, size, and thickness as specified in the work order.

- Equipment Calibration: Check the calibration stickers on measurement tools like digital calipers and micrometers. Ask to see the calibration records to ensure they are tested regularly.

- In-Process Hold Points: A great factory uses "hold points." These are planned pauses in production where a quality inspector must verify a critical step, like a weld joint or a dimensional check, before work can continue.

- Non-Destructive Testing (NDT): For metalwork, ask how they inspect welds. They should be using tools like fillet gauges and borescopes for internal checks.

Evaluate Bonding and Polishing Quality

For museum-grade fixtures, the final finish is critical. You must evaluate the factory's ability to produce flawless surfaces. Spend time in the polishing department and ask operators to explain their process.

For a mirror-like polish on stainless steel, a skilled operator follows a careful, multi-step process:

- Starts with coarse grinding to remove surface defects.

- Progresses through several rounds of grinding with increasingly finer sandpaper.

- Applies consistent, light pressure to avoid creating new marks.

- Uses a very fine grit (2000-4000) and a polishing compound for the final gloss.

- Cleans and inspects the surface, reapplying compound if needed.

For acrylic, look for different techniques depending on the part. These may include hand polishing for small details, flame polishing for smooth edges, or vapor polishing for high-precision optical clarity.

Note: Before polishing acrylic, workers should always clean the surface thoroughly with soapy water. They should also test their method on a small, hidden area first to prevent damage.

Observe In-Process Quality Control

In-process quality control (IPQC) is the heartbeat of a reliable factory. You need to see quality checks happening in real-time. Ask to see the IPQC checklists and watch inspectors use them. A good IPQC system is organized by production stage.

| Stage | Key Checks | Example Metrics |

|---|---|---|

| Incoming Inspection | Verify raw materials against spec sheets. | Material dimensions, Lot numbers |

| In-Process Inspection | Spot checks during production. | Feature measurements, Machine parameters |

| Final Inspection | Full product check before release. | Pass/fail criteria, Visual defect counts |

Advanced factories also use Statistical Process Control (SPC). This is a data-driven method for monitoring the manufacturing process. They use tools like control charts to track process variations. This allows them to spot potential problems and correct them before a defective part is made.

Check Packaging for Fragile Items

Your audit is not complete until you have inspected the packaging area. A beautiful fixture can be ruined by poor packaging. This is especially true for fragile items shipped internationally.

Look for a dedicated area where products are carefully packed. Best practices include:

- Custom Crating: The factory should build custom wooden crates designed for the exact dimensions of your product. This minimizes movement and risk of damage.

- Shock Absorption: Crates should use shock-absorbing materials like foam padding or specialized Skid-Mates to protect items from impact and vibration.

- Moisture Protection: For international shipping, look for moisture barriers like vapor bags and desiccants inside the sealed crate.

- Clear Labeling: All sides of the crate must be clearly labeled with handling instructions (e.g., "Fragile," "This Side Up"), weight, and content details.

- Securing Parts: Any moving or loose components on the fixture should be secured with bands or shrink wrap to prevent movement during transit.

A factory that invests in robust, custom packaging demonstrates a true commitment to delivering a perfect product.

Phase 3: Assessing Specialized Capabilities

The final phase of your audit confirms the factory has the specialized skills for your project. A certificate proves a system exists, but this step proves the OEM can deliver museum-quality results.

Evaluate Expertise with Museum-Grade Materials

You must verify the factory understands the materials your project requires. For museum-grade acrylic, ask about its specific properties. A knowledgeable supplier will discuss:

- UV Protection: It should block up to 99% of UV rays to prevent fading.

- Optical Clarity: It must have high light transmission (>98%) and an anti-reflective coating.

- Durability: The material needs to be shatter-resistant and abrasion-resistant.

Their understanding of these details shows true expertise.

Review Their Project Portfolio

A project portfolio is proof of past performance. Look for experience with high-profile institutions, such as the Louvre Abu Dhabi or The Design Museum in London. Do not just look at pictures. Analyze the complexity of their past work. A strong portfolio shows they can manage projects with clear objectives and deliver results.

Interview Key Personnel

You should speak with the people who will manage your project, especially the Quality Control Manager. A qualified manager will have:

- A technical background in engineering or a related field.

- Strong analytical skills to interpret data and find root causes.

- Excellent people skills to lead their team effectively.

Their expertise is crucial for maintaining high standards throughout production.

Request and Assess a Prototype

A prototype is the ultimate test of a factory's capabilities. This step is a key part of how to audit a factory for complex fabrication. When you receive the prototype, check for:

- Seal Effectiveness: Ensure gaskets are seated properly to prevent air leakage.

- Material Safety: Verify they used non-hazardous materials with no volatile organic compounds (VOCs).

- Structural Stability: The fixture must be stable and secure.

A physical prototype reveals issues that virtual simulations often miss.

Verify On-Site or Third-Party Lab Collaboration

A top-tier OEM must have a way to test materials. Ask if they have an on-site lab or work with a certified third-party lab. A well-equipped lab uses tools like spectrophotometers to verify color and scanning electron microscopes (SEM) to inspect surface finishes. This capability ensures material purity and quality from start to finish.

You now have a complete framework for how to audit a factory. A successful audit combines document review, on-site inspection, and capability assessment. This process helps you manage risks and improve product quality. A trustworthy OEM has verifiable certifications and an active Quality Management System. They also show proven skill in specialized fabrication.

Use this guide to confidently choose a manufacturing partner. Strong partnerships, like those between Nike and Huajian, are built on shared values and trust. Your audit builds that foundation.

FAQ

How long does a factory audit take?

A typical on-site manufacturing audit takes one to two days. You should plan for more time if your project is very complex. A thorough audit requires careful observation and verification, so do not rush the process.

What if a factory's ISO 9001 certificate is expired?

You should see an expired certificate as a major red flag. It means the factory's quality management system is not currently verified. You should not partner with a supplier who cannot maintain their core certifications.

What is the biggest red flag during an on-site audit?

The biggest red flag is a disconnect between documents and reality. The factory may have a perfect Quality Management System (QMS) on paper. If workers do not follow the procedures on the factory floor, the system is useless.

Can I perform a factory audit remotely?

You can complete the document review (Phase 1) remotely. However, you cannot properly assess on-site processes or specialized capabilities without a physical visit. A factory visit is essential for a complete and effective audit.

Remember: Seeing the process with your own eyes is the best way to verify quality. ✅

See Also

Selecting a Certified Acrylic OEM Partner: Your Guide to Vetting

SGS Certification in Acrylic: Understanding Its Process and Manufacturing Value

Ensuring Collector Safety: A 5-Point Compliance Checklist for Products

Effectively Briefing Manufacturers: Your Guide for Custom Collectibles Production

Expert Tips for 2025 from a Custom Acrylic Display Manufacturer