How Packaging Protects Displays for Global Shipping

A multi-layer system is how your packaging protects displays for global shipping. This high-quality packaging is essential for your custom acrylic displays.

High-quality acrylic is a durable material for acrylic displays. This systematic packaging, however, prevents damage to your acrylic displays. The process ensures the quality and durability of all acrylic displays. Your acrylic displays arrive ready for your hospitality setting. The quality of the acrylic ensures its durability during transit. This guide provides clear steps for protecting all of your acrylic displays. These displays demand careful handling.

Essential Surface Protection

The first step in your packaging process protects the acrylic surface itself. Your custom acrylic displays have a beautiful finish. You must shield this finish from cosmetic damage. Scratches, scuffs, and abrasions can easily mar the surface of acrylic displays during transit. Proper surface protection maintains the high quality and visual appeal of your displays. This initial layer is fundamental to the durability of the final product.

Protective Film Application

You should apply a protective film directly to the acrylic. Low-Density Polyethylene (LDPE) film is an excellent choice for this task. This material is transparent and non-toxic. It sticks to the surface of the acrylic without needing strong glue. This quality ensures you can peel it off easily, leaving no sticky residue behind.

Pro Tip: Before you apply the film, make sure the acrylic surface is completely clean. Wiping it down prevents dust and debris from getting trapped. Trapped particles can cause scratches on your acrylic displays. A smooth application is key for effective packaging.

This film acts as a primary shield for your acrylic displays. It guards the displays against minor damages that can happen during handling. This step is crucial for the overall durability and quality of the acrylic.

Soft Material Wrapping

After applying the film, you will wrap the acrylic displays in a soft material. This secondary layer provides cushioning. It protects the displays from minor vibrations and bumps. Good materials for this step include:

- Micro-foam sheets

- Bubble wrap

These soft materials add another layer to the packaging. They help absorb small shocks. This wrapping process further ensures the durability of your acrylic displays. It keeps them secure and prevents movement that could damage the acrylic. This careful packaging prepares your displays for the next stage of protection, ensuring they arrive in perfect condition. The right materials are essential for quality results.

How Packaging Protects Displays from Impact

After protecting the surface, you must shield your displays from major impacts. Global shipping involves rough handling, drops, and constant movement. Shock absorption is the primary defense for your custom acrylic displays. The right packaging protects displays by creating a buffer zone that absorbs and dissipates force. This prevents structural damage to the acrylic, such as cracks or breaks. Proper impact packaging is essential for the safety and durability of your items.

Cushioning for Custom Acrylic Displays

You need to immobilize your custom acrylic displays inside their box. Custom-cut inserts made from high-density foam are the best solution. Polyethylene (PE) foam is an excellent material for this job. Its effectiveness comes from its density and compression strength.

Foam Density Explained Foam density is measured in pounds per cubic foot (pcf). Higher density foams support heavier loads and provide superior shock absorption. They resist compression, absorb impact energy, and then rebound to their original shape. This quality is vital for protecting delicate acrylic displays.

Your packaging customization should specify a foam density appropriate for your displays. Polylam foam planks, for example, come in densities from 1.2 to 9.0 pcf. Using the correct materials ensures the durability of the acrylic. This level of customization creates a snug fit that stops the displays from shifting during transit.

Reinforcing Corners and Edges

The corners and edges of your acrylic displays are the most vulnerable points. An impact on a corner concentrates force in a small area, making it a common failure point. Your packaging must include extra protection for these areas.

You should use reinforced corner and edge protectors. These pieces are often made from dense foam, molded plastic, or heavy-duty cardboard. They fit snugly over the corners of your custom acrylic displays, providing an essential layer of defense. This simple step significantly improves the overall quality and durability of the packaging. It ensures your acrylic displays have 360-degree protection, completing the system that packaging protects displays from harm.

Internal Structural Support

Your packaging's internal structure is the skeleton that protects your acrylic displays. This design is a blueprint that safeguards the acrylic from impacts and vibrations during shipping. Even with a strong outer box, you need this internal support. It accounts for the weight and fragility of your custom acrylic displays. This step ensures the structural safety of the acrylic displays.

The Inner Box System

You should use a box-in-box method for your acrylic displays. This technique, also called double-boxing, adds a significant layer of protection. It is the best way to ship expensive or fragile acrylic displays. The process is simple:

- Place your cushioned acrylic display inside its own box.

- Put that smaller box inside a larger, sturdy shipping box.

- Ensure there is at least two inches of space on all sides between the inner and outer box.

This space is not left empty. You will fill it with cushioning materials. This customization creates a buffer zone. The outer box absorbs the initial shock, while the inner box provides a second line of defense for the acrylic. This packaging method greatly improves the chances that your displays arrive in perfect condition.

Filling Empty Voids

Empty space inside a shipping box allows your custom acrylic displays to move. This movement increases the risk of damage. You must fill all empty voids to immobilize the contents. Filling these gaps is a critical part of your packaging customization. It stabilizes the inner box and absorbs any remaining shocks.

Different materials offer unique benefits for your custom packaging. Air pillows are lightweight and save on shipping costs. Crinkle paper offers a premium look and is often made from recycled materials. Your choice of materials depends on the specific needs of your acrylic displays.

Properly filling voids maintains the structural integrity of the entire package. This final custom step ensures the high quality of your acrylic displays. It prevents heavy acrylic from wearing through the box due to constant vibration.

Exterior Packaging for Hospitality Destinations

The final layer of your packaging is the outer shell. This exterior barrier is the first line of defense against the rigors of international shipping. Your choice of materials must account for heavy handling, stacking pressure, and environmental conditions at the final hospitality destination. This robust exterior ensures the internal packaging protects displays effectively.

Heavy-Duty Outer Boxes

You must select a heavy-duty corrugated box for your custom acrylic displays. The strength of the box is critical for the durability of the acrylic displays inside. For heavy or fragile acrylic displays, you should choose double-wall or triple-wall boxes.

| Feature | Double-Wall Boxes | Triple-Wall Boxes |

|---|---|---|

| Construction | Two layers of fluting | Three layers of fluting |

| Strength | Good for most heavy items | Strongest option for very heavy displays |

| Best Use | General shipping of acrylic displays | Maximum protection for high-value acrylic displays |

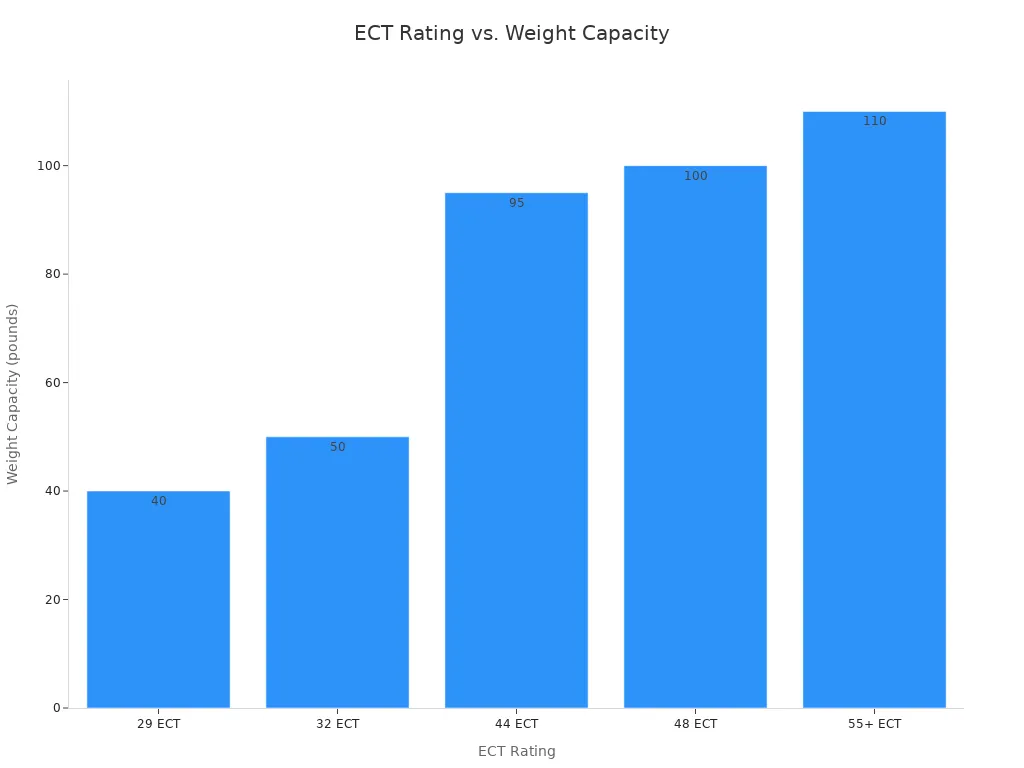

To verify a box's strength, you should check its Edge Crush Test (ECT) rating. This rating measures how much weight a box can handle before it crushes. For shipping heavy acrylic displays internationally, you need a box with a high ECT rating.

Pro Tip: For shipments over 50 pounds, choose a box with an ECT rating of at least 44. This ensures the packaging has the stacking strength needed for palletizing and warehouse storage.

Upgrading to Wooden Crates

For extremely large, heavy, or valuable custom acrylic displays, you should upgrade to wooden crates. These protective cases offer superior durability and protection. When using wood for international shipping, you must follow ISPM 15 regulations. This global standard prevents the spread of pests.

- The wood must be heat-treated to a core temperature of 56°C for at least 30 minutes.

- Each piece of wood must have an official ISPM 15 stamp.

Failure to comply can result in your shipment being rejected at customs. This step is essential for smooth international delivery of your acrylic displays. The right packaging ensures your acrylic displays arrive safely.

Securing the Box for Global Shipping

You must properly seal your packaging to complete the process. The tape you use is just as important as the box itself. Environmental factors like temperature and humidity can weaken adhesives. Your packaging must withstand these conditions. For heavy-duty boxes holding acrylic displays, you need strong tape.

- Water-activated tape creates a permanent bond with the box, adding rigidity and showing evidence of tampering.

- Reinforced filament tape contains fiberglass strands that provide extra strength for heavy custom acrylic displays.

Using the right tape ensures your packaging remains sealed throughout its journey. This final step guarantees the durability of the entire system, protecting your acrylic displays until they are unboxed.

Your packaging protects displays by following four key stages. You protected the acrylic surface, cushioned the acrylic displays from impact, supported the acrylic displays internally, and used a durable outer shell for the acrylic displays. This systematic packaging ensures your custom acrylic displays arrive perfectly for international shipping.

Investing in this packaging for your custom acrylic displays is smart. It prevents costly damage to your acrylic displays and protects your hospitality project's success. This approach ensures your acrylic displays, acrylic signs, and all acrylic displays arrive ready for use. This packaging protects all your acrylic displays.

FAQ

Why is LDPE film needed for your acrylic displays?

You use film on your acrylic displays. The film protects the acrylic surface of the acrylic displays. Your acrylic displays need this care. The acrylic is delicate. Your acrylic displays are an investment. This film protects the acrylic. The acrylic displays stay perfect. Your acrylic displays are safe. The acrylic is protected. The acrylic is safe. The acrylic is beautiful.

What is the best foam for cushioning acrylic displays?

You need PE foam for your acrylic displays. This foam cushions the acrylic displays. It protects the acrylic displays during handling. The foam keeps your acrylic displays safe. Your acrylic displays are protected. The acrylic is secure. The acrylic is safe. The acrylic is protected. The acrylic is safe. The acrylic is secure.

Do all international shipments of acrylic displays need ISPM 15 crates?

You need crates for heavy acrylic displays. This rule applies to wooden crates for international shipping. The wood protects the acrylic displays. This ensures your acrylic displays clear customs. Your acrylic displays are safe. The acrylic is protected. The acrylic is safe. The acrylic is protected. The acrylic is safe. The acrylic is secure.

Can I reuse boxes for my acrylic displays?

You should not reuse boxes for your acrylic displays. A new box protects your acrylic displays. This ensures the safety of your acrylic displays. Your acrylic displays deserve new boxes.

- The acrylic is safe.

- The acrylic is protected.

- The acrylic is safe.

- The acrylic is protected.

- The acrylic is safe.

- The acrylic is secure.

- The acrylic is valuable.