Why old packaging protects displays poorly abroad

Imagine your team at an international trade show. You uncrate the custom acrylic display. Its condition is your brand’s first impression. Sadly, 1 out of every 10 shipments arrives damaged, a common issue for businesses.

Common packaging methods, like bubble wrap in a standard box, are a primary cause of this damage. Old packaging protects displays poorly against the unique stresses of global transit.

You need a better strategy to ensure your brand shines on the world stage. This guide shows why those methods fail and what a truly protective strategy involves.

Acrylic's vulnerability during global shipping

You chose acrylic for its sleek, modern look. Its clarity and polish make your products stand out. However, this material has a hidden weakness. It is surprisingly fragile under the harsh conditions of international shipping. Understanding these vulnerabilities is the first step toward protecting your investment.

The fragility of acrylic displays

Acrylic appears robust, but it is a rigid plastic that can become brittle. Temperature and humidity changes during transit are its primary enemies. As your display moves from a climate-controlled warehouse to a cold cargo hold, its structural integrity is at risk. Extreme environmental shifts cause the material to expand and contract, creating internal stress.

This effect worsens in cold, dry air.

- Acrylic can become brittle at temperatures below 11°C (52°F) in low humidity.

- It loses its ability to absorb impacts below 5°C (41°F).

- By -3°C (27°F), nearly all acrylic types are highly susceptible to shattering.

A small jolt in these conditions can cause a crack or a full fracture.

The compounded risks of transit abroad

Global shipping exposes your display to a constant barrage of forces. During handling for both air and sea freight, your crate may experience shocks and drops equivalent to 1.0 g of acceleration. The journey itself adds more stress from multiple directions.

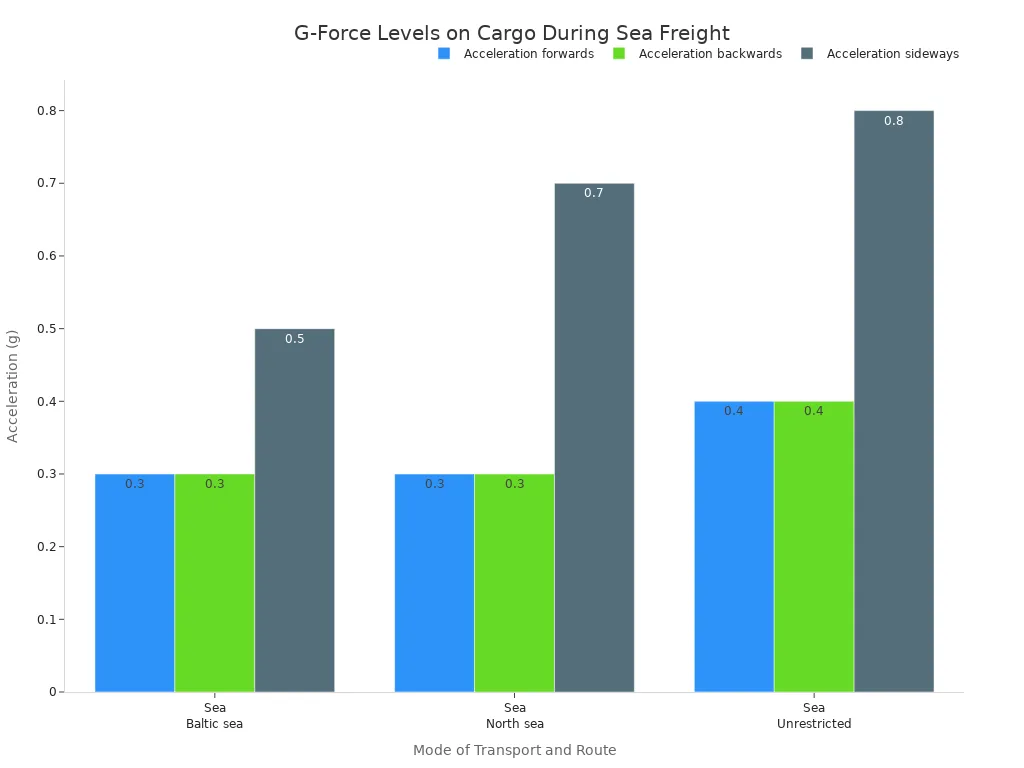

Consider the forces on a standard sea shipment:

| Mode of transport | Acceleration acting forwards | Acceleration acting backwards | Acceleration acting sideways |

|---|---|---|---|

| Sea Baltic sea | 0.3 g | 0.3 g | 0.5 g |

| Sea North sea | 0.3 g | 0.3 g | 0.7 g |

| Sea Unrestricted | 0.4 g | 0.4 g | 0.8 g |

Beyond physical forces, your shipment faces procedural risks. Each stop at a port or customs facility adds another layer of handling.

Note: Any issues with your shipping documents can trigger extra inspections. Incomplete paperwork or unpaid duties may cause customs officials to hold, open, and physically inspect your package, increasing the chances of accidental damage.

Your display is handled multiple times by different teams, compounding the risk with every move.

Why traditional packaging fails

You understand the risks of global transit. Now, you must see why your go-to packaging methods are inadequate. A standard box and some bubble wrap might work for a local delivery, but they fail under the extreme pressures of international shipping. Effective packaging protects displays by countering specific forces, something traditional materials cannot do.

Poor shock and impact absorption

You likely wrap your display in bubble wrap, thinking its air-filled pockets provide enough cushion. Bubble wrap does offer some shock absorption for minor bumps. However, it is not designed to handle the sustained vibrations and major impacts common in global freight. Cardboard alone provides even less protection.

Think about it this way: a study on bottled beer found that normal vibrations during truck transport were enough to affect product quality. If simple road travel can damage a sturdy glass bottle, imagine what constant G-forces at sea do to your large, fragile acrylic display. Materials like bubble wrap compress and lose their effectiveness over a long journey, leaving your display vulnerable.

Abrasion from internal movement

When your package experiences a shock, the display moves. Even a small shift inside the box creates friction. This movement against the packaging materials or even against itself causes surface damage. Your display's pristine, polished surface is at high risk.

If your delicate equipment tilts beyond a safe angle, it can internally crack, shift, or warp. This movement can also lead to misalignment of assembled parts, rendering the display unusable upon arrival.

Constant, small vibrations cause a different kind of damage. This repeated rubbing can lead to:

- Scuffs and scratches that dull the finish

- Impact-induced dents on edges and corners

- Material loss and thinning of the acrylic surface

- Surface cracks that compromise the display's structure

Lack of custom structural support

You place your display in a standard cardboard box. That box is then loaded into a container with tons of other cargo. Standard corrugated boxes are not built to withstand heavy stacking pressure. Their structural integrity depends entirely on their corners and edges, which are easily compromised.

Your box may fail for several reasons:

- Overloading: The weight of other cargo simply crushes your box from the top or sides, transferring all that force directly to your display.

- Poor Quality Materials: Many standard boxes use thin cardboard or weak recycled fibers that tear easily.

- Inadequate Design: A single-wall box is no match for the compressive forces in a packed shipping container.

- Environmental Factors: Humidity in a sea container weakens cardboard, causing it to sag and collapse even without direct pressure.

Weakness to moisture and punctures

Your package faces more than just physical force. It is also exposed to the environment and the cargo around it. Cardboard readily absorbs moisture from the air, rain on a loading dock, or condensation inside a container. A damp box loses up to 60% of its strength, making it highly susceptible to crushing and tearing.

Punctures are another common hazard. A standard box offers almost no defense against sharp objects.

- Your shipment can be punctured by contact with other crates, machinery, or unsecured cargo.

- If your own display has sharp corners, intense vibration can cause it to puncture the box from the inside out.

Each of these failures—poor shock absorption, internal movement, structural collapse, and punctures—exposes your acrylic display to damage. Traditional packaging simply isn't engineered to prevent them.

How modern packaging protects displays

To avoid the pitfalls of traditional methods, you must adopt a modern, multi-layered packaging strategy. This approach is not about simply wrapping your display; it is about engineering a complete system where each component serves a specific protective function. A modern system anticipates the forces of global transit and neutralizes them before they can cause damage. This is how professional packaging protects displays and ensures your investment arrives intact.

Engineered interior protection

The first layer of defense begins inside the box. You must immobilize your display completely. Generic fillers like bubble wrap or loose-fill peanuts fail here because they allow for movement, which leads to abrasion and impact damage. You need a solution engineered for your specific product.

Custom-cut, high-density foam is the industry standard for superior protection. Materials like expanded polyethylene (EPE) are not just cushions; they are engineered shock absorbers.

Using advanced design processes like CNC milling, a packaging specialist creates foam inserts that match the exact contours of your display. This perfect fit holds your product securely, preventing any shifting during transit.

This method eliminates the primary cause of scratches and internal stress. The foam's cellular structure is designed to dampen constant vibrations from road, sea, or air transport, much like it reduces fatigue for passengers in vehicles. It also absorbs and disperses the force from sudden drops or shocks.

Compare the performance of basic fillers versus an engineered solution:

| Feature | Loose-Fill Peanuts | Custom Foam Inserts |

|---|---|---|

| Product Security | Allows shifting and settling | Immobilizes the product completely |

| Shock Absorption | Minimal and inconsistent | Excellent and predictable |

| Vibration Dampening | Poor; transfers vibrations | Excellent; absorbs vibrations |

| Presentation | Messy and unprofessional | Clean, professional, and high-end |

A well-designed interior packaging protects displays by creating a secure, shock-absorbent cocoon that moves as a single unit.

Rigid exterior defense

Your display’s second line of defense is a rigid exterior shell. A standard cardboard box cannot withstand the crushing weight of other cargo or resist punctures. For international shipping, you must upgrade to a custom-built wooden crate or a durable, reusable hard-shell case made from materials like plywood or high-impact plastic.

These containers provide a robust frame that protects against impacts, punctures, and compression. A professionally constructed wooden crate often uses:

- Framing made from 2x4 or 2x6 lumber.

- Walls made from a minimum of 1/2" plywood or Oriented Strand Board (OSB).

- Assembly with 4-inch screws, not just nails, for maximum structural integrity.

For all international shipments using solid wood, your crate must be ISPM 15 compliant.

Important: ISPM 15 is an international standard to prevent the spread of pests through wood packaging. The wood must be heat-treated (HT) to a core temperature of 56°C for 30 minutes and stamped with an official mark. Failure to comply can result in your shipment being rejected, fumigated, or destroyed at the border at your expense.

Note that engineered woods like plywood and OSB are exempt from ISPM 15 rules, which can simplify your logistics. This rigid exterior is the armor your display needs to survive the harsh realities of a global supply chain.

Essential surface-level safeguards

The final layer of protection is applied directly to your display’s most delicate surfaces. The polished face of an acrylic display is highly susceptible to fine scratches and static buildup. A complete packaging strategy addresses these micro-level risks.

First, you must apply a non-abrasive, anti-static protective film directly to the acrylic. During transit, static electricity naturally builds up, attracting dust and debris that can get trapped and cause scratches. In some cases, static can even interfere with printed graphics on the display.

An anti-static film dissipates this charge immediately, keeping surfaces clean and free from abrasive particles. These films are engineered for durability and clarity, providing crucial protection without leaving residue.

Second, even high-density foam can cause minor scuffing during long journeys with constant vibration. To prevent this, you should use a soft liner, like a thin sheet of microfoam or a soft cloth wrap, between the protective film and the custom foam inserts. This final layer ensures that no part of the packaging abrades the pristine surface of your display. This level of detail is how modern packaging protects displays from every conceivable threat, ensuring a showroom-quality arrival.

Your standard box and bubble wrap are a liability for global events. They fail against the unique forces of international shipping. A damaged display presents an unprofessional front and harms your brand's reputation. Modern, custom packaging protects displays by neutralizing these risks. You should see this solution as a direct investment in your project's success and client retention.

Ensure your displays arrive in showroom condition. Contact a packaging specialist to engineer a custom transit solution for your next global event. 🚀

FAQ

Is custom packaging worth the cost?

You should view custom packaging as an investment, not a cost. It protects your brand's reputation and prevents expensive repairs. This initial expense safeguards your display's value and ensures a successful event, saving you money long-term.

What is ISPM 15 and why does it matter?

ISPM 15 is a global standard for treating wood packaging to prevent pest spread. Your shipment must use compliant, heat-treated (HT) wood.

Warning: Non-compliance can lead to customs rejecting, fumigating, or destroying your crate at your expense. ☠️

Can I reuse my custom packaging?

Absolutely. You can design durable wooden crates and hard-shell cases for multiple uses. This approach maximizes your return on investment. It also simplifies logistics for future events, making setup and breakdown more efficient and predictable.

What if my display has electronic components?

You must protect sensitive electronics from static and moisture. Your packaging specialist will use anti-static films and foam. They may also add vapor barrier bags with desiccants to absorb humidity, ensuring your components arrive fully functional.