The Prototyping to Rollout Process for Hotels

You aim to create a memorable guest experience that builds guest loyalty. The challenge for hotels is scaling a vision without issues, ensuring brand loyalty. A structured prototyping to rollout process provides the answer. Success in hospitality requires intense collaboration. This collaboration ensures your brand's promise is met. Effective collaboration between your design and operations teams is vital for your services. This collaboration is the foundation of great hospitality. The financial stakes for hotels are high.

| Category/Renovation Type | Cost Range (2025) |

|---|---|

| Midscale Hotels (upgrading bathrooms, replacing furniture) | $20,000–$40,000 |

| Luxury Hotels (custom designs, high-end finishes) | $100,000–$150,000 |

This process demands collaboration. Strong collaboration mitigates risks from labor shortages and material costs. Your project's success hinges on this collaboration. It is the core of your hospitality services. This collaboration ensures quality for hotels. This collaboration is key to hospitality. This collaboration drives success.

The Prototyping to Rollout Kickoff: Design & Sampling

This initial phase is where your vision takes physical form. It is the most creative and collaborative stage of the entire prototyping to rollout process. Strong collaboration here prevents costly errors later. You will define every detail, from the grand concept to the specific materials, ensuring your final product is beautiful, durable, and true to your brand.

Conceptual Design & Brand Alignment:

Your furniture and fixtures are not just objects; they are storytellers. This stage ensures they tell the right story. Effective collaboration between design teams and brand strategists is crucial for success in the hospitality industry.

Translating Brand Standards:

You must translate your brand’s core identity into tangible design elements. Your furniture should communicate your unique value proposition. This creates a cohesive guest experience and builds customer loyalty. Look at how successful brands achieve this:

- The Bvlgari Hotel Milan uses custom furniture with sintered stone and soft leather to reflect its sophisticated style.

- 1 Hotel Brooklyn Bridge uses reclaimed materials and abundant plant life to align with its biophilic, eco-luxe identity.

- Moxy Times Square incorporates multi-functional swing chairs and communal tables, creating versatile social spaces that match its playful brand.

- YOTEL employs self-service kiosks, a fixture choice that reinforces its tech-forward, efficient brand promise.

Balancing Aesthetics & Functionality:

A beautiful chair that breaks easily is a liability. You must balance stunning aesthetics with the practical demands of a high-traffic hospitality environment. This balance is key to providing excellent services. Your design choices should improve the functionality and flow of spaces. Consider these approaches:

- Multifunctional Spaces: Design flexible areas that serve multiple needs. A breakfast nook can become an evening lounge. This adaptability meets the growing demand for "bleisure" travel and maximizes your space's utility.

- Local Influences: Integrate local art, crafts, and architectural elements. This offers an authentic experience that connects the guest to the destination.

- Wellness and Health: Create spaces that support guest well-being. This can include ergonomic seating or areas designed for relaxation.

- Pet-Friendly Design: Respond to the growing demand for pet-friendly travel. Use durable, easy-to-clean materials and innovative pet furniture to enhance the experience for every customer.

Using Data & AI to Inform Design:

You can leverage technology for smarter design choices. Data helps you understand how guests use your spaces. This knowledge allows for optimization of layouts and furniture selection. The use of artificial intelligence in hotels is growing rapidly. AI can analyze guest feedback to identify preferences. This data-driven approach supports better personalization of services. Automation in design software can also speed up the creation of initial concepts. The smart application of artificial intelligence in hotels helps you anticipate customer needs. This focus on artificial intelligence in hotels is a key part of new service development.

Finalizing Initial Specifications:

This step documents your initial vision. Your team will create a detailed package with inspiration images, preliminary sketches, and material palettes. This document becomes the foundation for the next stage. It requires intense collaboration to ensure every stakeholder is aligned. This specification package guides the entire design and manufacturing process, making it a critical tool for your hospitality project.

Material Selection & Durability:

The materials you choose directly impact your budget, maintenance schedule, and guest safety. In the hospitality sector, durability is not negotiable. This is where your investment proves its long-term value.

Sourcing Commercial-Grade Materials:

Residential furniture is not built for the rigors of hospitality use. You must specify commercial-grade materials designed for high traffic and heavy use. The differences are significant.

| Feature | Commercial-Grade Furniture | Residential-Grade Furniture |

|---|---|---|

| Durability | Built for heavy use; features reinforced joints and stronger frames. | Designed for lighter, occasional use. |

| Materials | Uses robust materials like solid hardwood, steel, and high-density foams. | May use particleboard, MDF, and lower-density foams. |

| Construction | Employs advanced techniques like mortise-and-tenon joints. | Uses simpler methods like dowels and screws. |

| Cost | Generally more expensive due to higher quality materials. | Typically more affordable. |

| Warranty | Comes with longer, more comprehensive warranties. | Warranties are typically shorter. |

| Safety Standards | Adheres to stricter safety and fire codes. | Meets basic residential safety standards. |

Pro Tip: You can also specify COM (Customer's Own Material) or COL (Customer's Own Leather). This allows you to source a specific fabric or leather from a preferred supplier and have the furniture manufacturer apply it. This gives you ultimate control over the final finish but requires careful collaboration and coordination.

Fabric & Finish Durability Testing:

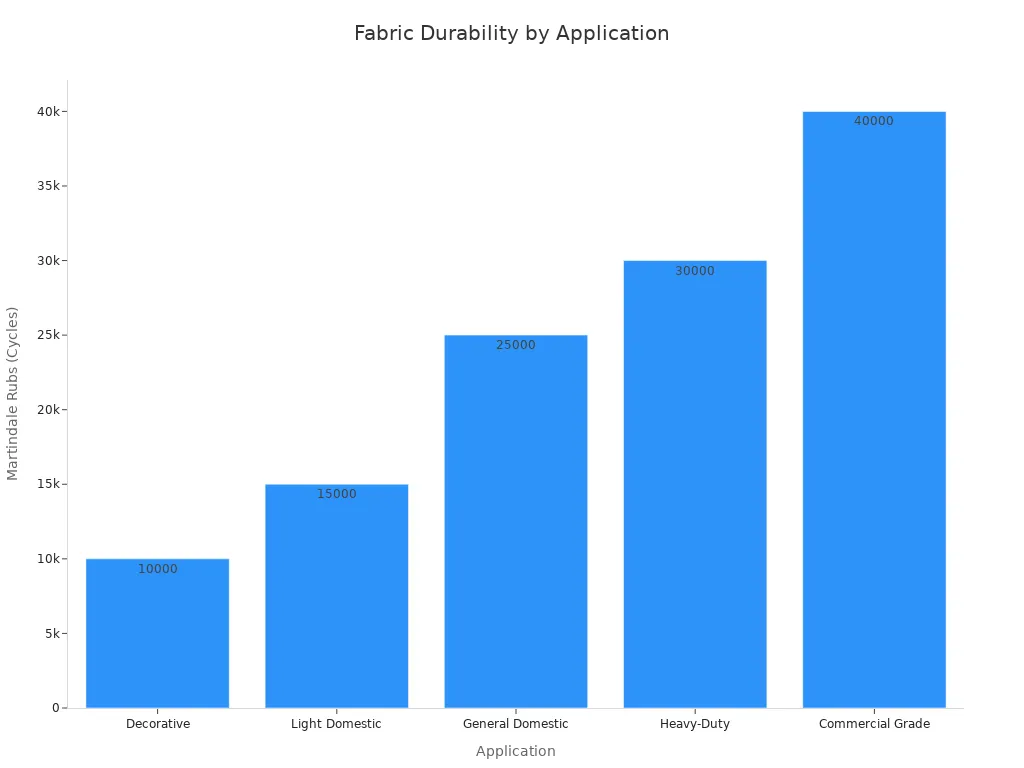

Fabrics in hotels must withstand constant use and cleaning. You can verify a fabric's durability using standardized abrasion tests. The two most common tests are Wyzenbeek and Martindale.

- Wyzenbeek Test: An operator rubs a cotton duck fabric back and forth along the warp and weft of the test fabric. The score is the number of "double rubs" the fabric endures before showing significant wear. For contract upholstery, you should look for a minimum of 15,000 double rubs.

- Martindale Test: This test uses a Lissajous pattern, rubbing the fabric in a figure-eight motion with worsted wool. For commercial-grade applications, you need a fabric that exceeds 30,000 cycles.

These tests provide objective data to ensure your chosen fabrics will last, protecting your investment and maintaining your property's appearance.

Compliance with Safety Standards:

Guest safety is your highest priority. All furniture and materials must comply with local and national fire safety regulations. Non-compliance can lead to legal liability and endanger your guests and staff. Key standards in the United States include:

- CAL 117-2013: A widely adopted standard for upholstered furniture. It requires materials to pass a smolder resistance test, which is crucial for preventing fires started by cigarettes.

- NFPA 260: This standard tests the cigarette ignition resistance of upholstered furniture components. It is a common requirement for commercial hospitality projects.

- CAL 133: A more stringent test for furniture in public spaces. It requires testing the entire piece of furniture, not just its components, for flammability.

Your manufacturing partner must provide documentation certifying compliance with all required standards for your project's jurisdiction.

Sustainable Sourcing Options:

Today's customer values sustainability. You can build brand loyalty by making environmentally conscious choices. Ask your suppliers about options like:

- FSC-Certified Wood: Wood sourced from responsibly managed forests.

- Recycled Materials: Fabrics made from recycled plastics or metals with high recycled content.

- Low-VOC Finishes: Finishes that release fewer volatile organic compounds, improving indoor air quality.

Sustainable sourcing demonstrates corporate responsibility. It also appeals to an important and growing segment of the travel market.

Prototype Creation & The Model Room:

This is the moment of truth. You move from drawings and specifications to a physical product. The prototype allows you to see, touch, and test your design in a real-world context before committing to mass production.

The Role of a Physical Sample:

A physical prototype is essential. It allows you to assess the comfort, stability, and overall quality of a furniture piece. You can check the finish, the feel of the fabric, and the craftsmanship of the joints. No rendering can replace the experience of interacting with a physical sample. This step is vital for gaining stakeholder confidence and ensuring the final product meets expectations.

Virtual Prototyping & Digital Twins:

Technology offers powerful tools to support the physical prototyping process. Virtual reality (VR) and digital twins are transforming hospitality design. The use of artificial intelligence in hotels helps create these models.

- A VR Hotel app allows your team to walk through a virtual room. You can assess furniture placement, scale, and sightlines before a single item is built. This level of automation and visualization saves time and money.

- Digital twin technology creates a detailed virtual replica of your physical space. You can use it to test different furniture configurations and finishes. This application of artificial intelligence in hotels streamlines design decisions. This collaboration tool helps teams visualize the final experience.

These tools, driven by artificial intelligence in hotels, do not replace the physical prototype but enhance the process, enabling faster iterations and better decision-making.

Building the Approved Model Room:

Once you approve the individual prototypes, you will assemble them in a model room, often called a mock-up room. This is a fully realized guest room, complete with furniture, fixtures, lighting, and finishes. It is the single most important checkpoint in the entire process. The model room allows all stakeholders—from ownership and design to housekeeping and maintenance—to experience the room exactly as a guest would. This is the ultimate test of your design and a cornerstone of effective collaboration.

Documenting the Final Sample:

After all stakeholders approve the model room, you must meticulously document every detail. This includes taking high-resolution photos, confirming all dimensions, and signing off on every finish and fabric. This "approved sample" becomes the gold standard. Your manufacturer will use this documentation to ensure every single piece produced for the full rollout matches the approved model room perfectly. This final act of collaboration locks in your quality standard for the rest of the project.

Stakeholder Feedback & Refinement:

Your model room is built. Now, you must test its success with the people who will build, use, and maintain it. This stage transforms a design showcase into a practical, vetted product. This intense collaboration is the final quality gate before you commit to large-scale production. Strong collaboration here protects your investment and ensures operational success for your hotels.

Formal Stakeholder Review:

You should schedule a formal review session with the primary project decision-makers. This meeting focuses on brand alignment, budget, and overall aesthetic approval. This initial collaboration sets the tone for the entire feedback process. Key attendees typically include:

- Ownership/Investors: They provide the ultimate financial approval.

- Brand Representatives: They ensure the room meets all brand standards and guest experience goals.

- Design Team: They present the design intent and answer questions about their choices.

- Procurement/Purchasing Agent: They confirm that the specified items align with the budget and sourcing strategy.

Cross-Departmental Feedback Loop:

This is where a design thinking approach becomes critical. A beautiful room that is difficult to clean or maintain creates long-term problems. You must actively seek feedback from the teams who will interact with the room daily. This practical collaboration is non-negotiable for successful hotels.

Pro Tip: Adopt a Design Thinking Mindset 🧠 You must move beyond aesthetics and ask: "How will this work in the real world?" Invite your operational teams into the model room and empower them to give honest feedback. This collaboration ensures the final product is not only beautiful but also functional and efficient.

You can structure this feedback loop to gather specific, actionable insights.

| Department | Feedback Focus | Example Questions |

|---|---|---|

| Housekeeping | Cleaning efficiency, durability of surfaces, ease of making beds. | Can you easily vacuum under the nightstand? Does the desktop finish show fingerprints? |

| Maintenance | Access to lighting, ease of repair, durability of mechanisms. | How difficult is it to change the lightbulb in this fixture? Are the drawer slides robust? |

| Operations | Guest flow, technology use, overall guest comfort and safety. | Is the desk chair comfortable for working? Are power outlets placed conveniently? |

This deep level of collaboration prevents costly operational headaches down the line.

Final Design Revisions:

You will collect all feedback and consolidate it into a single list of required changes. This step requires careful project management and clear communication. The design team works with the manufacturing partner to address each point. This collaboration might involve adjusting a table leg's height, changing a fabric, or repositioning a power outlet. Each revision must be documented and approved. This is the last chance to perfect the design before locking it in for the full prototyping to rollout process.

Securing Final Sign-Off:

Once all revisions are complete and the model room is updated, you must secure final, formal approval from every stakeholder. This is a critical step that prevents any future disputes about the final product. This final act of collaboration solidifies the master standard.

You should follow a clear process for this sign-off:

- Conduct a Final Walkthrough: Invite all stakeholders for one last review of the approved model room.

- Present Final Documentation: Provide updated drawings, photos, and specification sheets that reflect all changes.

- Obtain Physical Signatures: Have authorized representatives from each group (ownership, brand, operations) physically sign a tag on each furniture piece and sign off on the final documentation.

This signed-off model room now becomes the "gold standard" for your project. This rigorous collaboration ensures every piece produced for your hotels will match this approved sample perfectly.

Phase 2: Pre-Production & Validation

You have an approved model room. This is your "gold standard." Now, you must transition from a single perfect room to a scalable, repeatable manufacturing process. This phase is about technical precision and risk mitigation. Strong collaboration here ensures your design intent is translated flawlessly into hundreds of units, protecting your budget, timeline, and brand reputation for all your hotels.

Designing the Guest Experience for Manufacturing:

This is where you translate the approved design into a detailed manufacturing blueprint. Your goal is to engineer the product for efficient, high-quality production. This requires intense collaboration between your design team and the manufacturer.

Design for Manufacturability (DFM):

You must adapt your design for efficient production. Design for Manufacturability (DFM) is a process where you proactively design products to be easy to manufacture. This collaboration with your production partner is key to controlling costs and timelines. Applying DFM principles delivers significant benefits:

- Lower Manufacturing Costs: You reduce material waste and streamline assembly, which decreases expenses.

- Faster Production: Efficient workflows enable faster mass production, helping you meet project deadlines and customer demand.

- Reduced Part Count: Minimizing the number of parts simplifies manufacturing, lowers inventory costs, and improves reliability.

- Use of Standard Parts: Opting for off-the-shelf components instead of custom ones shortens lead times and simplifies quality assurance.

- Design for Ease of Assembly: You design products with manufacturing constraints in mind, avoiding complex or expensive production steps.

Value Engineering for Budget Adherence:

Value engineering is a systematic method to improve the "value" of your FF&E without sacrificing quality or design intent. It is not about choosing the cheapest option. It is about finding the smartest one. This is a critical step for optimizing your budget.

- Strategic Material Selection: You can use different grades of materials on a single piece. For example, use a durable high-pressure laminate (HPL) on a desktop while using a more affordable low-pressure laminate (LPL) on unseen surfaces.

- Component Flexibility: You can design casegoods to serve multiple purposes. A headboard can integrate lighting, USB ports, and storage, adding value for the guest, especially in smaller rooms.

- Prioritize Essential Areas: You allocate more of your budget to high-impact areas like lobbies and guest rooms that directly affect the customer experience. You can then explore cost-saving options for less critical spaces.

Creating Production-Ready Shop Drawings:

Shop drawings are the manufacturer's instruction manual. They are far more detailed than design sketches. These drawings translate the final design into a technical language that fabricators understand. Your team must review and approve every detail. Essential elements include:

- Plan, Elevation, and Section Views: These drawings show the item from every angle, including bird's-eye views and cross-sections that reveal internal construction.

- Precise Dimensions: You must include exact measurements for the overall piece and each individual component to ensure a perfect fit.

- Material & Hardware Specifications: The drawings list every material, from the type of wood to the specific model of drawer slide or hinge.

- Joinery and Assembly Details: They illustrate exactly how parts connect, ensuring structural integrity.

- Finishing Details: The drawings specify the exact paint color, stain, and sheen for every surface.

Finalizing Technical Specifications:

Alongside the shop drawings, you will create a final technical specification document. This document is the definitive contract for quality and materials. It leaves no room for interpretation. It lists every approved material, finish, fabric, and hardware component by name, model number, and supplier. This level of detail is the foundation of your quality control program and a cornerstone of successful new service development in hospitality.

Supply Chain & Partner Vetting:

Your manufacturing partner and supply chain are as critical to your project's success as the design itself. Selecting the right partners mitigates risk and ensures a smooth prototyping to rollout process.

Selecting Manufacturing Partners:

Choosing a manufacturer is a major decision. You need a true partner, not just a supplier. Whether you choose a domestic or overseas factory, your vetting process must be thorough.

| Criteria | Domestic Manufacturing | Overseas Manufacturing |

|---|---|---|

| Cost | Higher upfront cost; better overall ROI. | Lower upfront cost; may require ordering 10% extra for damage. |

| Lead Times | Generally shorter. | Often longer and subject to shipping delays. |

| Quality | More consistent quality control. | Quality can be inconsistent without rigorous oversight. |

| Communication | Easier; fewer time zone or language barriers. | Can be a major challenge; slower response times. |

| Risk | Lower risk of IP theft and shipping damage. | Higher risk of IP issues, damage, and tariffs. |

| Safety | Adheres to strict U.S. material safety standards. | May use materials not compliant with U.S. regulations. |

A True Partnership 🤝 Look for a manufacturer who acts as a cohesive team member. They should provide detailed documentation, anticipate installation challenges, and offer a comprehensive warranty (a 5-year warranty is standard). This level of collaboration is essential for the hospitality industry.

Establishing a Resilient Supply Chain:

A resilient supply chain can withstand disruptions like shipping delays or material shortages. Your goal is to build a system with foresight and flexibility. This is key to delivering excellent services to every customer.

You can build resilience through several key actions:

- Build Strong Supplier Relationships: Foster open communication and trust with your key vendors.

- Diversify Your Suppliers: Avoid relying on a single source for critical components to protect against shortages.

- Incorporate Demand Forecasting: Use data to anticipate needs, which allows for better inventory management and optimization.

- Use Technology: Leverage procurement and freight optimization tools for better transparency. This automation enhances your ability to provide consistent services.

Negotiating Contracts & Timelines:

Your contract is your ultimate protection. It must be detailed and legally sound. Work with your legal and procurement teams to create an agreement that clearly defines:

- Scope of Work: A precise description of all deliverables.

- Payment Schedule: Milestones for payment tied to performance.

- Production & Delivery Timeline: Firm dates for key project phases.

- Quality Standards: References the approved sample and technical specifications.

- Penalties and Remedies: Clauses that address delays or quality failures.

Factory Audits & Quality Systems:

Before signing a contract, you should conduct a factory audit. This can be done in person or through a trusted third-party inspector. The audit verifies that the manufacturer has the capability, capacity, and quality control systems to execute your project. This step confirms they can deliver the quality your guest and customer expect.

Pilot Run & Process Validation:

Before launching full-scale manufacturing for your hotels, you must test the production line. A pilot run of a small number of units (e.g., one full guest room's worth of furniture) allows you to validate every step of the process.

First Article Inspection Run:

The First Article Inspection (FAI) is a critical quality gate. The very first unit that comes off the full production line is rigorously inspected. You or your third-party inspector will compare this "first article" side-by-side with the original signed-off prototype from the model room. This meticulous collaboration ensures that the mass-production setup perfectly matches the approved standard before you commit to producing hundreds or thousands of units.

Testing Production Line Consistency:

During the pilot run, you must test for consistency across all units produced. Your quality standards must be specific and measurable. For example, instead of "high-quality finish," your standard should be "finish must be uniform in color with no visible scratches, bubbles, or runs when viewed from 24 inches under normal lighting." This ensures every piece delivers the same high-quality experience.

| Inspection Phase | Key Verification Points |

|---|---|

| Assembly Verification | Joint integrity, alignment, hardware installation. |

| Finishing Evaluation | Color consistency, surface quality, coating thickness. |

| Functionality Testing | Smooth operation of drawers, doors, and moving parts. |

| Packaging Inspection | Proper cushioning, carton strength, and correct labeling. |

This focus on consistency is vital for operational efficiency and delivering reliable services.

Comparing Pilot Units to Prototype:

Each unit from the pilot run is compared directly against the "gold standard" prototype. You check every dimension, finish, fabric, and function. This is your last chance to catch any deviations that may have occurred when moving from a one-off sample to a production line setup. This step is crucial for the personalization of the final guest experience.

Finalizing QC Checkpoints:

Based on the findings from the pilot run, you will finalize the Quality Control (QC) checklist. This document will be used by inspectors on the factory floor for the entire production run. It defines all the critical checkpoints for in-line and final inspections. This use of automation in quality processes ensures every piece meets your standard, providing a consistent experience for every customer.

Logistics & Installation Planning:

You have a perfect product design and a validated manufacturing process. Now you must master the final, critical step before rollout: logistics. This stage is about moving your FF&E from the factory floor to the guest room efficiently and without damage. This requires intense collaboration between your team, your manufacturer, and your logistics partners. A strong plan here prevents chaos on-site and keeps your project on schedule.

Phased Delivery Scheduling:

You cannot simply have all your furniture arrive at once. A phased delivery schedule is essential for managing a large-scale renovation or new build. This approach ensures a smooth workflow for your installation teams. This collaboration between logistics and on-site teams is vital.

- Source Modular Items: You can significantly reduce installation time by using modular or pre-finished items. Things like vanity kits, casegoods, and LED packages can cut schedules by 20-50%.

- Ship in Sequence: Your manufacturer should ship items in installation order. For example, pallet one contains everything for rooms 101–120, and pallet two is for rooms 121–140. This logical packing simplifies on-site staging.

- Use Just-in-Time (JIT) Deliveries: You can schedule containers to arrive just as they are needed. This prevents overwhelming the site but requires a small buffer to account for potential shipping delays.

- Label Everything: You should insist that all items are labeled with QR codes and clear room/zone IDs. This simple step minimizes mishandling and helps crews quickly stage items for installation. This level of detailed collaboration saves hours of work.

Freight & Warehousing Strategy:

Your freight and warehousing strategy is the backbone of your delivery schedule. Choosing the right logistics partner is crucial for a successful project. This collaboration ensures your FF&E is handled professionally from start to finish.

Partner with a Pro 🤝 You should partner with a comprehensive, asset-based logistics firm. A true partner manages everything from FF&E liquidation and storage to final installation. They use state-of-the-art electronic inventory systems to track your items, check them against specifications upon arrival, and ensure timely deliveries for phased installations. This end-to-end collaboration is key for hotels.

Your strategy should define how items are received, stored, and moved to the site. This includes securing off-site warehousing if necessary and planning for a secure on-site staging area. This collaboration with your logistics provider protects your assets.

Detailed On-Site Installation Plan:

A "day-of attack plan" is non-negotiable. This detailed itinerary outlines every step of the installation process, ensuring everyone knows their role and the schedule. This plan is the result of deep collaboration between your installer, your operations team, and your project manager.

Before installation day, your installer must conduct a thorough site visit. This visit confirms all critical details.

- Access Points: They will measure doorways, hallways, and elevators to ensure furniture will fit.

- Staging Areas: They will identify secure, accessible areas to stage FF&E before installation.

- Site Conditions: They will verify that the area is clean, utilities are active, and the site is free of construction debris.

- Resource Needs: They will plan for access to power outlets and other necessary resources for assembly.

This proactive collaboration prevents costly surprises, like a sofa that cannot fit through a doorway. The plan must be realistic; an overly ambitious schedule creates more problems than it solves. This collaboration ensures a smooth process for your hotels.

Waste Management & Site Cleanup:

The installation process generates a significant amount of waste, from cardboard boxes to plastic wrap and pallets. Your installation plan must include a clear strategy for waste management. This is a final, important point of collaboration.

You must define responsibilities clearly in your contract with the installer.

- Debris Removal: Who is responsible for removing all packaging materials from the site daily?

- Existing FF&E: If you are renovating, who is responsible for removing and disposing of the old furniture?

- Final Condition: What is the expected condition of the installation site after the work is complete?

A clean and organized site is a safe site. Proper waste management is not just about aesthetics; it is a critical component of a professional and efficient installation process for all hotels. This final collaboration ensures a clean handover.

Rollout Execution for Hotels: Installation & Handover

This final phase is where your vision becomes a reality across your entire property. The prototyping to rollout process now shifts from design to disciplined execution. Success here depends on rigorous quality control, precise logistics, and meticulous on-site management. This intense collaboration ensures every room delivers a consistent, high-quality guest experience.

Mass Production & Quality Assurance:

With your approved standard, you can now launch full-scale production. This stage requires constant vigilance to ensure every piece matches the quality of the original prototype. This collaboration with your manufacturer is vital for your services.

Launching Full-Scale Manufacturing:

You give the green light for mass production. Your manufacturing partner uses the approved shop drawings and QC checklists to replicate the "gold standard" sample hundreds or thousands of times. This is a critical step for your hotels.

In-Line & Final QA Checks:

Quality is not just checked at the end. Inspectors perform in-line checks at every stage of production, from raw material cutting to final assembly. This proactive collaboration catches errors early. Final QA checks confirm each finished piece meets every specification before it is packaged.

Third-Party Inspection & Reporting:

You can hire an independent third-party inspector for unbiased oversight. This inspector provides detailed reports with photos, confirming that production aligns with your standards. This adds another layer of quality assurance and accountability to your services.

Ensuring Finish & Color Consistency:

Your inspectors use color-calibrated tools and lightboxes to check finishes. They compare each batch to the approved master sample. This ensures a guest moving from the lobby to their room sees a consistent and intentional design, which is key for customer satisfaction.

Phased Delivery & Warehousing:

Getting your FF&E to the site safely and on time requires a robust logistics plan. This collaboration between your manufacturer and logistics partner prevents on-site chaos and keeps your project on schedule.

Managing Factory-to-Site Logistics:

Your logistics partner manages the complex journey from the factory to your property. This includes container booking, customs clearance, and freight forwarding. Strong collaboration here is essential for providing excellent services.

Local Staging & Inventory Management:

Items often arrive at a local warehouse before moving to the hotel. Here, crews check inventory against purchase orders. This optimization step ensures all pieces are accounted for and undamaged before they reach the installation site.

Just-in-Time (JIT) Deliveries:

You can use a JIT strategy to manage inventory and meet customer demand efficiently. This approach delivers items to the site exactly when they are needed for installation.

- You hold minimal inventory on-site, reducing clutter and the risk of damage.

- You trim procurement expenses and cut carrying costs.

- This method is highly effective for maintaining product quality and reducing waste.

Real-Time Shipment Tracking:

Modern logistics partners provide real-time tracking. This automation gives you full visibility into your shipment's location. You can anticipate arrivals and adjust your installation schedule accordingly, improving your services.

On-Site Installation & Review:

The final step is installing the FF&E and confirming every detail is perfect. This requires expert team management and a meticulous review process. This final collaboration ensures a flawless customer experience.

Installation Team Management:

Your installation leader directs the on-site crew. They follow the detailed installation plan to work efficiently and safely. This leadership is crucial for the success of large-scale projects in hotels.

Property Protection During Install:

You must protect your property from damage during installation. Installers should use protective padding for floors and walls. They also employ specialized equipment like compact dollies to maneuver items safely, preventing damage to the building and the new furniture. This careful work protects your investment.

Room-by-Room Punch List:

After installation, you conduct a punch list inspection in every room. This process ensures each space meets brand and owner standards, which is vital for personalization of the guest experience.

- You check each room for any deficiencies or damage.

- You repair or replace any damaged items before final approval.

- You cross-check the installation with brand guidelines for consistency.

- You perform functionality tests on all items to confirm they work correctly.

Final Walkthrough & Acceptance:

You conduct a final walkthrough with all key stakeholders. This is the last chance to identify any issues. Once you are satisfied, you formally accept the project. This final act of collaboration using automation in your checklists completes the installation, delivering a perfect space for every customer.

Post-Installation & Warranty:

Your project is not finished when the last piece of furniture is installed. This final stage ensures the long-term value of your investment. This phase requires continued collaboration to transition from project execution to daily operations for your hotels.

Project Closeout Documentation:

You must receive a comprehensive closeout package from your partners. This documentation is your official record of the project. This final act of collaboration ensures your team has all the information it needs for future maintenance and management. Your package should include:

- Information on exact materials used

- Details on where materials were sourced

- Service history for relevant items, like HVAC systems

This intense collaboration also ensures you receive all operational documents.

- Warranties for installed FF&E

- Manuals for all equipment and furniture

- Maintenance information and cleaning guides

- A project closeout report summarizing the process

Manufacturer Warranty Management:

You need a clear system to manage all manufacturer warranties. This collaboration with your procurement and maintenance teams is essential. You should organize these documents so your team can access them easily when a repair is needed. This proactive collaboration saves time and money over the lifespan of the FF&E.

Future Defect & Repair Process:

You must establish a clear process for handling future defects. This collaboration between your on-site team and the manufacturer ensures issues are resolved quickly. Define the steps your staff should take when they discover a damaged item. This collaboration should outline who to contact and what information to provide. A smooth repair process minimizes room downtime. This ongoing collaboration is key to maintaining quality standards in your hotels.

Planning for Attic Stock:

You should plan for "attic stock," which is a small inventory of spare FF&E for quick replacements. This strategic collaboration protects your guest experience from disruptions caused by out-of-service rooms. A common industry rule is to keep 1%–2% of each room’s FF&E items in storage. This collaboration helps you budget effectively. Common items to keep in your attic stock include:

- Chairs

- End tables

- Headboards

- Dressers

- Nightstands

The quantity depends on your property size. This final collaboration with your purchasing team ensures your hotels are prepared.

| Room Count | Suggested Attic Stock Quantity |

|---|---|

| 50 rooms | 1 extra item per type |

| 100 rooms | 1–2 of each item |

| 200+ rooms | 2–4 of each high-use item |

You have followed the journey from a single concept to a fully realized hotel interior. This path requires meticulous prototyping, rigorous validation, and disciplined rollout. Strong collaboration ensures a positive guest experience. This collaboration builds guest loyalty.

This structured process is your most effective strategy. It protects your brand and ensures your hotels deliver a quality guest experience. This intense collaboration builds lasting loyalty. The successful collaboration between teams is key for all hotels. This builds customer loyalty.

This roadmap empowers you to invest confidently, knowing you can achieve success.

FAQ

Why is a model room so important?

A model room lets you test the design with your operations teams. You can find practical issues before mass production. This step ensures your final services meet both guest expectations and operational needs, preventing costly mistakes.

What is the difference between DFM and value engineering?

DFM (Design for Manufacturability) makes a product easier to build. Value engineering finds cost savings without losing quality. Both processes work together to improve your project's efficiency and help you adhere to your budget.

How long does the prototyping to rollout process take?

Timelines vary based on project complexity. A full project can take from 6 to 12 months or more. Your schedule depends on:

- Design complexity

- Manufacturing location

- Logistics planning

Clear planning is essential for your services.

Should I choose a domestic or overseas manufacturer?

Your choice depends on your project's priorities. Domestic partners often provide faster communication and lead times. Overseas partners may offer lower costs but can have higher risks. You must vet all potential partners for quality services.

What is a First Article Inspection (FAI)?

A First Article Inspection (FAI) compares the very first production unit against your approved prototype. This critical quality check ensures the factory setup is correct before you begin mass production for your hotels. It is your final quality gate.

How much attic stock should I order?

You should plan for 1–2% of your total FF&E order as attic stock. This inventory allows for quick replacements of damaged items. It helps you keep rooms available and maintains a consistent guest experience.

How can I ensure my design is practical for daily use?

You must involve your housekeeping and maintenance teams in the model room review. Their feedback on cleaning and repairs is vital. This collaboration helps create durable, functional furniture and provides excellent services for hotels.