What is Extruded Acrylic Sheet? Definition, Process, and Applications

One-Sentence Definition

Extruded acrylic sheet is a flat, transparent plastic material made from poly(methyl methacrylate) (PMMA) resin, produced by continuously melting and shaping the resin through an extrusion process, resulting in consistent thickness and high optical clarity (ISO 7823-2).

Detailed Explanation

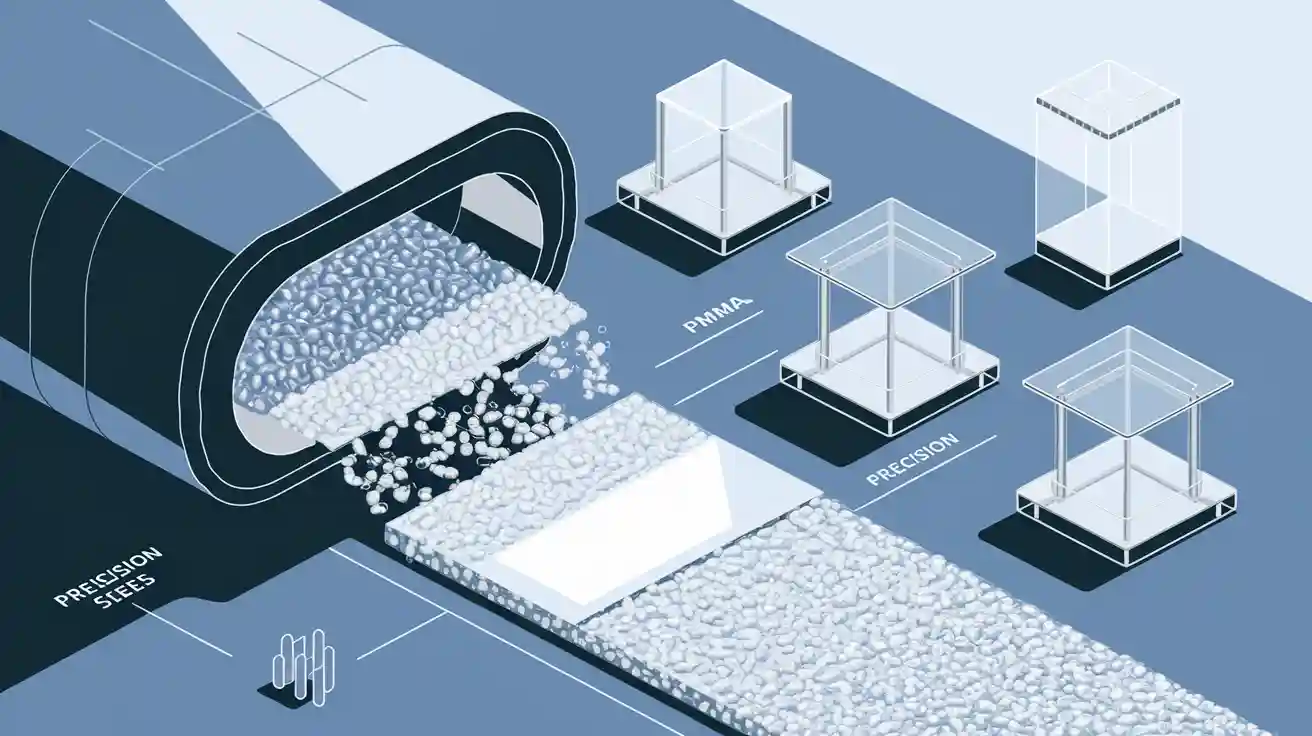

Extruded acrylic sheets are manufactured by heating PMMA pellets until molten, then forcing the material through a shaping die to form a continuous sheet. This process ensures uniform thickness and allows for large-scale, cost-effective production. The resulting sheets are lightweight, strong, and transmit up to 92% of visible light—making them an excellent alternative to glass for many applications. Compared to cast acrylic, extruded sheets are easier to cut, machine, and thermoform, though they may have slightly lower surface hardness and chemical resistance.

Key Components and Features

Material: PMMA (Polymethyl Methacrylate), a clear, durable thermoplastic.

Manufacturing Process: Continuous extrusion—melting PMMA pellets, shaping through a die, cooling, and cutting to size (WeeTect).

Performance:

High optical clarity (up to 92% light transmission)

Consistent thickness and dimensional stability

Good impact resistance (2–3 times stronger than glass)

Weather and UV resistance

Cost-effective for high-volume production

Easy to fabricate, cut, and thermoform

Performance Comparison: Extruded vs. Cast Acrylic Sheet

Property | Extruded Acrylic | Cast Acrylic |

|---|---|---|

Thickness Uniformity | Excellent | Good |

Optical Clarity | High | Highest |

Surface Hardness | Good | Better |

Chemical Resistance | Good | Better |

Cost | Lower | Higher |

Ease of Fabrication | Easier | Good |

Color/Finish Options | Moderate | Wide Range |

Source: Regal Plastics, WeeTect

Real-World Applications

Extruded acrylic sheets are widely used in:

Signage and Displays: Retail display stands, illuminated signs, and exhibition booths

Protective Barriers: Sneeze guards, safety partitions, and machine guards

Architectural Glazing: Windows, skylights, and interior partitions

Furniture and Storage: Custom storage boxes, trays, and modern furniture

Lighting: Diffusers and covers for LED and fluorescent lighting

Aquariums and Vivariums: Transparent enclosures requiring strength and clarity

TOYIN specializes in custom extruded acrylic products, offering high-precision cutting, thermoforming, and printing for display racks, storage boxes, protective covers, and furniture. With advanced manufacturing and global delivery, TOYIN supports tailored solutions for retail, office, and home environments.

Related Concepts

PMMA (Polymethyl Methacrylate): The base resin for acrylic sheets, known for its clarity and durability.

Cast Acrylic Sheet: Produced by pouring liquid acrylic into molds; offers higher optical purity and surface hardness, but at a higher cost.

Polycarbonate Sheet: Another clear plastic, more impact-resistant than acrylic but less scratch-resistant and more expensive.

Acrylic Resin: The raw material used for both extruded and cast acrylic sheets.

For more on the differences between acrylic types, see Regal Plastics' comparison guide.

Visual Aids

Process Diagram: See above for a visual overview of the extrusion process.

Performance Table: Refer to the comparison chart for quick reference.

Looking for high-quality, custom extruded acrylic solutions? Explore TOYIN’s product range and request a quote today.