Analyzing Display Cost Drivers Explained

The price of exhibiting at events continues to climb. Many exhibitors planning to exhibit see consistent increases.

- The average price per square foot for exhibit space has risen 5% since 2014.

- Material handling and labor costs also see annual increases.

Booth space and design often account for 60% of total costs. Successful exhibiting depends on managing these costs effectively. Understanding the cost drivers explained in a budget is the key for any team looking to exhibit.

Breaking Down Trade Show Booth Cost

An exhibit team must first understand the foundational expenses. Industry research shows the booth rental fee alone accounts for about one-third of total show expenses. This makes the physical space the single largest line item for most companies. The total trade show booth cost depends heavily on two initial decisions: the booth's footprint and its structural design. These choices create a major price fork. A company can choose a simple, pre-configured exhibit or a fully custom-built environment. This decision directly impacts all subsequent costs.

Booth Footprint and Height

The size and location of an exhibit space are primary cost drivers. A larger footprint naturally commands a higher price. The location on the show floor also matters. Spaces near main entrances or major aisles often have premium pricing. The show's location itself plays a huge role in determining U.S. exhibiting costs, with major convention cities having higher costs. Domestic exhibiting costs can vary significantly from international exhibiting costs.

The final price for an exhibit space depends on several factors. These include the nature of the show, the host city, the specific venue, and the size of the space you rent.

For example, the cost per square foot changes based on the event's location.

| City/Context | Cost Per Square Foot |

|---|---|

| Las Vegas (CES 2018) | $36 to $43 |

| Overall Booth Space | $20 to $45 |

The Average Trade Show Booth Cost

Exhibitors often ask about the average trade show booth cost. The answer depends on the exhibit size and complexity. A small 10x10 exhibit is a common starting point for many businesses. A larger 20x20 island exhibit offers more presence and opportunities for engagement. The cost of a booth can range from a few thousand dollars to well over six figures.

The following table shows some general estimates for exhibiting.

| Booth Size | Estimated Cost Range (USD) |

|---|---|

| 10x10 | $5,000 - $16,500 |

| 20x20 (Island) | Up to $80,000 |

These figures represent a wide range because the final price is a sum of many parts. The initial space rental is just the beginning. The choice between a modular rental exhibit and a new custom-fabricated exhibit will dramatically alter the final number. A custom build provides a unique brand experience but requires a larger investment in design, materials, and labor. This is a key factor when planning your budget for exhibiting.

Build Type and Material Costs

After an exhibitor selects a booth footprint, the next major decision involves the physical structure of the exhibit. The choice between a custom-fabricated environment and a modular system is a critical fork in the road. This decision directly influences the budget, timeline, and logistical planning for the event. The overall booth design and construction process hinges on this initial choice.

Custom vs. Modular Displays

Custom and modular displays serve different strategic purposes and come with distinct cost structures. A custom exhibit offers unparalleled brand expression, while a modular exhibit provides flexibility and reusability.

- Custom Fabrication: This approach involves traditional craftsmanship like carpentry and welding. It creates a unique, permanent-feeling structure. A custom booth is designed for maximum impact and can make a powerful statement on the show floor.

- Modular Systems: These exhibits use pre-engineered components that fit together in various configurations. They are designed for adaptability, allowing an exhibitor to change the layout for a different size or location.

The following table breaks down the key differences:

| Aspect | Modular Exhibit | Custom Exhibit |

|---|---|---|

| Initial Cost | Moderate investment | Higher upfront investment |

| Flexibility | High; reconfigurable for different shows | Low; built for a specific design |

| Design | Many design options with stock parts | Fully unique and brand-specific |

| Setup Time | Generally faster installation | Longer setup, often needs specialists |

| Transport | Lighter and more compact | Requires specialized shipping and storage |

Note: While a custom build has a higher initial price, a well-built custom exhibit can last for years. This longevity can justify the investment if a company's brand identity is stable. Modular systems, on the other hand, offer immediate savings. Their lightweight and compact nature can reduce shipping, drayage, and storage costs by $5,000 to $20,000 over the life of the exhibit.

Premium vs. Economy Materials

The materials used in an exhibit are a significant cost driver. The choice affects not only the initial price but also the display's durability, weight, and overall quality. Exhibitors can choose between high-end materials for a premium feel or economical options to manage the budget.

Premium materials like hardwoods, solid surfaces, and metal create a high-quality look and feel. Economy materials such as laminates, PVC, and tension fabric offer a professional appearance at a lower price point. The price difference can be substantial.

| Material Type | Price Per Sq. Ft. (Material Only) |

|---|---|

| Hardwood | $5 – $15 |

| Laminate | $2 – $5 |

The material choice also impacts long-term value. Durable materials like aluminum frames are strong, lightweight, and can be reused for many show cycles. They provide a sturdy framework for an exhibit of any size. Softer materials like fabric graphics are less expensive and easy to replace, offering flexibility for messaging. However, they require careful handling. The right material selection balances visual impact, durability, and the overall costs of exhibiting. This ensures the exhibit can be adapted for a new location or event without a complete rebuild.

Graphics and Customization

Graphics are the visual heart of an exhibit. They communicate brand identity and messaging. The production methods and the level of customization directly influence the final budget. An exhibitor must balance visual impact with cost-effectiveness.

Graphic Production Methods

The complexity of a graphic design is a primary cost driver. Simple, single-layer graphics are less expensive than multi-layered designs. Complex animations or high-resolution models demand more artist hours and rendering power. This increases production time and cost. The overall quality of the final product depends on these choices. A more intricate exhibit design requires more resources.

The table below shows how specific factors affect production costs.

| Factor of Complexity | Impact on Cost and Time |

|---|---|

| Number of Layers | More layers directly increase manufacturing costs. |

| Custom Specifications | Unique requirements often need special tools or skills, raising the price. |

| Design Complexity | Complicated layouts require more processing and can lead to higher costs. |

Full Custom vs. Rental Designs

Exhibitors face a key choice: purchase a full custom exhibit or use a rental design. This decision significantly impacts the budget. A custom rental exhibit typically costs about one-third of a custom-built purchase.

- Full Custom Purchase: This offers a completely unique structure but comes with a high upfront investment. The owner is also responsible for all storage, shipping, and maintenance fees.

- Rental Design: Renting provides major cost savings. An exhibitor avoids fees for storage, repairs, and shipping. This frees up the budget for other priorities, like a larger booth size or a better location on the show floor.

A rental exhibit is not a compromise on branding. Exhibitors can fully customize rentals with unique graphics, flooring, lighting, and digital technology. This allows a company to create a powerful brand experience for a specific event size or location. Renting is an excellent strategy for infrequent exhibiting or for companies that want to test a new design.

Technology Integration

Technology transforms a static display into an engaging experience. Integrating digital elements is a powerful way to attract visitors and communicate a message. However, these components are significant cost drivers. An exhibitor must carefully budget for hardware, software, and the specialized labor needed for setup.

Interactive Elements and Software

Interactive technology makes an exhibit memorable. It invites attendees to participate rather than just observe. These elements directly impact the budget.

- Touchscreens and Tablets: These are common for product demos and information kiosks. Costs include hardware rental or purchase, plus software development or licensing fees.

- Lead Capture Apps: Specialized software simplifies collecting attendee data. This investment improves post-show follow-up but adds a recurring or one-time cost.

- Gamification: Games or contests increase booth traffic. Developing a custom game for an exhibit requires a larger budget for programming and design.

The size and complexity of the interactive setup determine the final price. A simple tablet display is much cheaper than a custom virtual reality experience.

Lighting and AV Systems

Lighting and audio-visual (AV) systems create the atmosphere of an exhibit. They guide attention and enhance the overall design. The cost varies widely based on the system's complexity. Basic spotlights are an economical choice. Advanced systems like programmable LED lights or large-scale video walls represent a much larger investment. The physical location of the booth can influence AV needs. A dark corner of the hall may require more lighting.

The right AV system can make an exhibit stand out. The size of a video wall, the number of speakers, and the complexity of the lighting grid all contribute to the total cost. These choices are essential for successful exhibiting. The booth's location also plays a role in power and rigging requirements.

On-Site Services: The Final Cost Drivers Explained

The final on-site services are crucial cost drivers explained in any event budget. An exhibitor's choices for labor, material handling, and utilities directly impact the total costs. Careful planning in these areas is essential for successful exhibiting. These final expenses can often surprise teams who focus only on the physical exhibit structure.

Labor for Installation and Dismantle

Union labor for installation and dismantle (I&D) represents a significant expense. Exhibitors must understand how labor rates work to manage the budget. Most venues have rules for straight time (ST), overtime (OT), and double time (DT). Smart scheduling helps control these costs. For instance, one hour of overtime can be cheaper than paying for a new four-hour minimum shift the next day. Planning setup during ST hours is a key strategy. Waiting until the day after the show to dismantle the exhibit can also prevent expensive OT charges.

Shipping and Drayage Fees

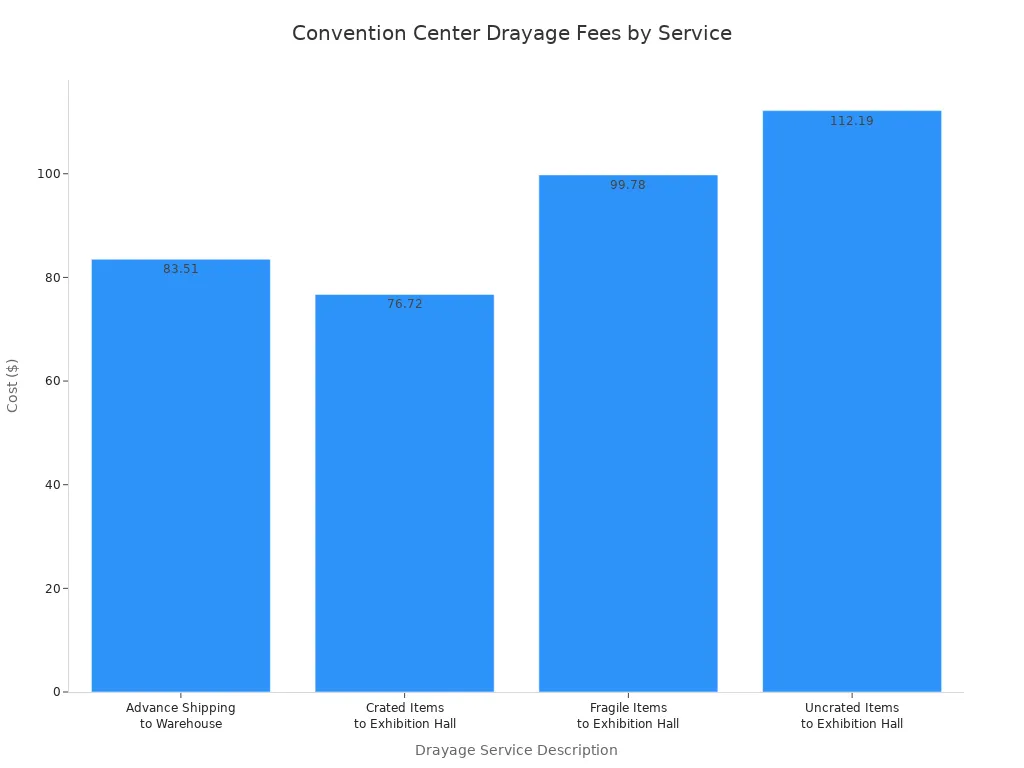

Drayage is a separate charge from shipping. It is the fee for moving an exhibit from the loading dock to the booth space and back. Show organizers, not the shipping company, charge for this service. Drayage fees are typically calculated by weight per 100 pounds (CWT). Rates for U.S. exhibiting costs can range from $60 to $160 per CWT.

A key to managing drayage is consolidation. Shipping one large 408-pound crate might cost $500. Shipping five small 25-pound boxes separately could cost $1,000 because each box is charged at a minimum weight.

The type of material also affects the price. Uncrated or fragile items cost more to handle than standard crated goods.

| Description | Cost (per CWT) |

|---|---|

| Advance Shipping to Warehouse for Storage | $83.51 |

| Crated Items Directly Sent to Exhibition Hall | $76.72 |

| Fragile Items Directly Sent to Exhibition Hall | $99.78 |

| Uncrated Items Sent Directly to Exhibition Hall | $112.19 |

Other On-Site Service Costs

Beyond labor and drayage, other on-site services add to the final bill. These are the last cost drivers explained in the budget. Electricity, internet access, and booth cleaning are common needs. Electrical costs vary by city and the amount of power an exhibit requires. Booth cleaning is another expense, often priced per square foot. Forgetting to budget for these necessary services can strain an exhibiting budget.

The final price of exhibiting is the sum of many deliberate choices. An exhibitor controls costs by setting clear goals for their exhibit. They must decide if the budget is best spent on a larger space, custom fabrication, or advanced technology. Understanding these cost drivers explained in the budget is key.

A clear discussion with an agency about the cost drivers explained helps find the best balance. This ensures the exhibit has a strong impact while staying on budget.

FAQ

What is the single biggest trade show expense?

The booth space rental fee is typically the largest single expense. This line item often accounts for about one-third of an exhibitor's total show budget. The physical footprint on the show floor represents a major initial investment for any team.

Is it cheaper to rent or buy an exhibit?

Renting an exhibit offers significant upfront savings. An exhibitor avoids costs for storage, maintenance, and repairs. A custom purchase requires a larger initial investment but can provide long-term value for companies with a stable brand and frequent exhibiting schedule.

How can an exhibitor reduce drayage costs?

Exhibitors reduce drayage fees through smart consolidation. Shipping items in a single, well-packed crate is more cost-effective than sending multiple small boxes.

This strategy helps avoid minimum weight charges that apply to each individual piece, lowering the total material handling bill.

Why is union labor a major cost driver?

Union labor rates for installation and dismantle (I&D) are a major cost. Venues have strict rules for straight time, overtime, and double time. Poor scheduling can lead to expensive overtime charges. Careful planning helps control these necessary on-site service expenses.