Streamline Your Production Workflow for Collectibles

You have a great idea for a collectible. The biggest challenge is turning that vision into a high-quality product through production. A structured production workflow is the key to successful manufacturing. This process guides the transition from a single prototype to mass production. It helps you control cost and ensure the final production quality meets high standards. Your timing is excellent, as the market shows strong growth.

The global collectibles market is expanding quickly.

Report Attribute

Details

Market revenue in 2025

USD 320.30 billion

Revenue forecast in 2033

USD 535.50 billion

Growth rate

CAGR of 6.6% from 2025 to 2033

This industry-standard path minimizes risks for your manufacturing journey. A solid production workflow ensures your final production quality is exactly what collectors expect. It is the best way to protect your prototype vision and achieve a successful production run.

Phase 1: Design for Manufacturability (DFM)

Design for manufacturability (DFM) is the first critical step in your product development journey. This phase focuses on designing your collectible so it can be produced efficiently and affordably. A successful design for manufacturability plan sets the foundation for the entire manufacturing process, ensuring high quality from the start.

The Goal of DFM for Collectibles

The main goal of design for manufacturability is to align your creative vision with practical production capabilities. This proactive approach helps you avoid costly problems later. Implementing DFM offers several key benefits for your project:

You reduce production costs by simplifying the design and using fewer parts.

You enhance product quality because the design matches the factory's abilities, leading to fewer errors.

You accelerate your time-to-market since an efficient design speeds up the entire manufacturing process.

You lower the risk of expensive design changes during production.

Early Manufacturer Collaboration

You should not complete the DFM phase alone. Collaborate with your chosen manufacturer as early as possible. Their experts provide invaluable feedback on your design's manufacturability. They can identify potential issues with materials, assembly, or scaling that you might overlook. This partnership is essential for a smooth transition into production.

Material Selection for Scale and Cost

Your choice of material directly impacts the final cost, durability, and quality of your collectible. For mass production, you need materials that are consistent, affordable, and suitable for your manufacturing methods. Mixed plastics and resins are common choices for scaling.

Specification | Mass-Produced Figure |

|---|---|

Material Quality | Mixed plastics & resins with cost focus |

Price Range | Lower: $10-$50 |

Durability | Generally robust for mass use |

These materials are sturdy and safe for handling. They offer great resilience and can hold vibrant colors, often exceeding expectations for their price point.

Design Optimization for Production

Sometimes, a feature that looks great on a prototype is too complex for mass production. You must simplify certain elements to ensure consistent quality and reasonable production times.

Pro Tip: Look for overly complex parts. Early Star Wars action figures provide a classic example. The first Darth Vader figure had a double-telescoping lightsaber. Kenner quickly simplified this feature for mass manufacturing by removing the complex telescoping mechanism. This change did not hurt the toy's success and made the production much more manageable.

Phase 2: Prototyping with Production in Mind

This phase moves beyond just the look of your collectible. The goal of prototyping with production in mind is to create samples that test your final manufacturing methods. This critical step in product development helps you confirm that your design can be made consistently and with high quality before you commit to full-scale production. It is the bridge from a single idea to a successful prototype to mass production run.

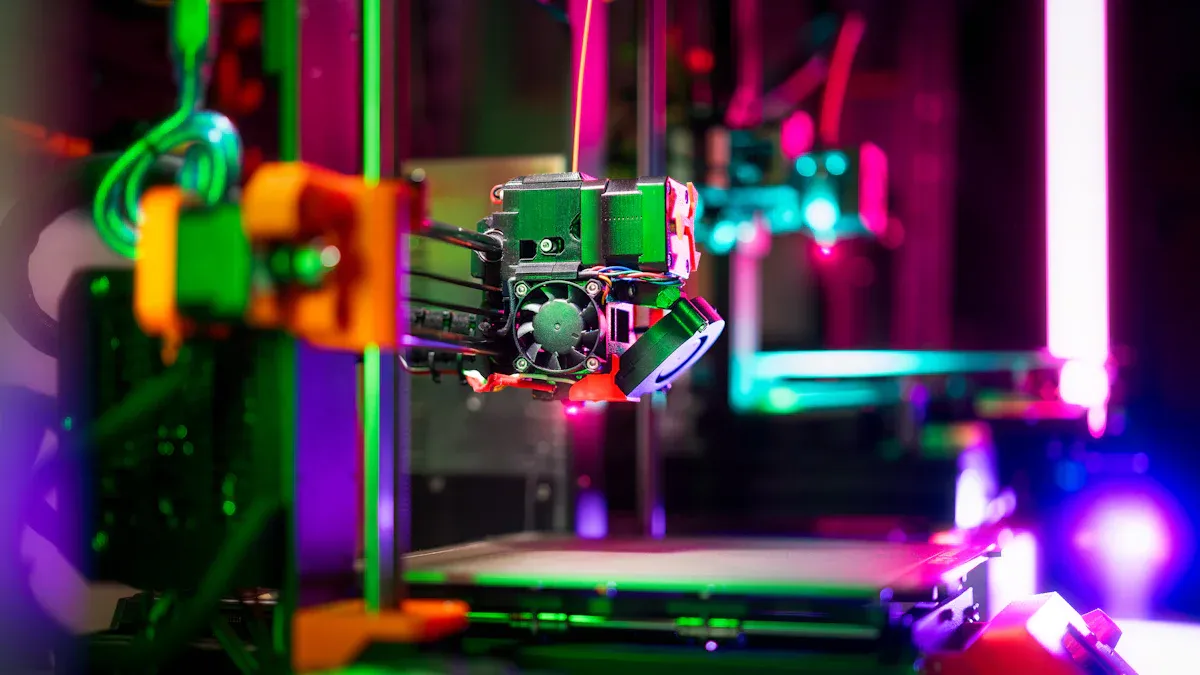

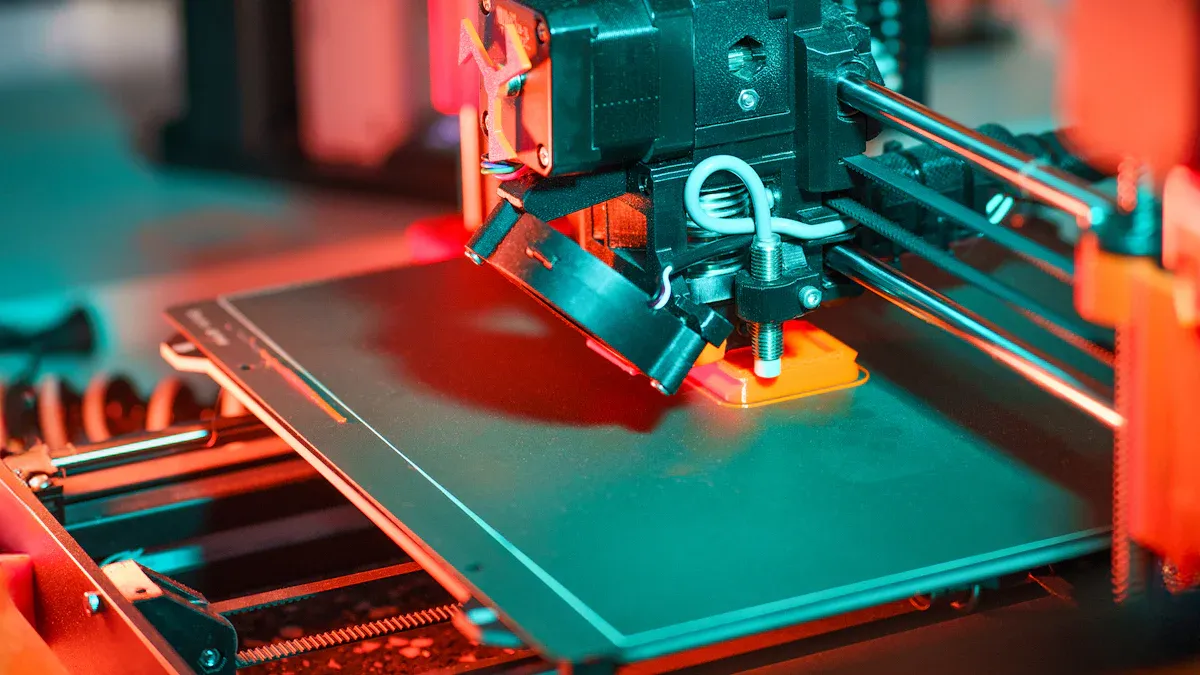

Choosing the Right Prototyping Method

You must select a method that matches your goals for this stage. Early 3D prints are great for checking the sculpt, but for testing the manufacturing process, you need something closer to the final product. Soft tooling and molded samples test fit and finish more accurately. Each method has its own benefits and drawbacks for your production.

Feature | 3D Printing | Resin Casting (Soft Tooling) |

|---|---|---|

Pros | Quick, flexible, good for complex shapes | Extremely detailed, great for small batches |

Cons | Slower speed, requires post-processing | Labor-intensive, less efficient |

Best For | Early sculpts, limited editions | Testing final details and finishes |

Validating Fit, Form, and Function

Your prototype must do more than just look good. You need to validate its physical characteristics. This means testing how different parts fit together (fit), checking the overall shape and feel (form), and ensuring any moving parts work correctly (function). This testing phase confirms that all components meet your requirements before you finalize the design for manufacturing.

Creating the "Golden Sample" Benchmark

After several iterations, you will approve a final prototype. This is your "Golden Sample."

🏆 What is a Golden Sample? The Golden Sample is the perfect, final version of your collectible that you and your manufacturer agree on. You should sign and date this sample. It becomes the absolute standard for quality that every single unit from the production line must match.

Your manufacturer will use this benchmark during the entire manufacturing process to ensure consistency.

Testing Paint, Finishes, and Packaging

The final details define the quality of your collectible. You must thoroughly inspect the paint application for even coverage and accurate details. Check that any gloss or matte finishes are uniform and durable. You should also test your packaging to ensure it protects the product during shipping. This careful review protects the final look and feel of your collectible, which is essential for meeting collector expectations and managing the final cost of production.

Phase 3: The Pilot Production Run

After approving your Golden Sample prototype, you enter the pilot production run. This is a limited, controlled pre-production run. It is your first real test of evaluating readiness for mass manufacturing. This phase uses the exact equipment and labor intended for full-scale manufacturing.

Purpose of a Small-Batch Pilot Run

You conduct a pilot run to manage risk. It helps you find and fix problems before you invest in a large production order. The primary goals of this run are to:

Validate your manufacturing process to ensure it works as intended.

Prevent costly recalls or reworks, saving you time and money.

The Bridge from Prototype to Production

The pilot run closes the prototype to production gap. It moves your project from a single perfect prototype to a repeatable process. This trial uncovers design flaws that were not obvious in the prototype stage. It also highlights any bottlenecks in the production line. This step is essential for a seamless transition from prototype to mass production.

Testing Production Tooling

This is your chance to test the final steel molds. During this stage of production process development, you might discover issues with the tooling. Common problems include resin shrinkage, warping, or excess plastic called "flash" from incorrect injection pressure. You can now optimize temperature controls and other machine settings. This pilot production and optimization ensures the manufacturing process creates consistent, high-quality parts.

Establishing QC Checkpoints

You must establish a system for robust quality control. This involves setting specific checkpoints along the assembly line. For example, you should inspect parts for cosmetic flaws right after molding. You can also track error rates to identify where failures happen. These quality control considerations help you build a roadmap for improvements and ensure every unit meets the standard of your Golden Sample prototype.

Finalizing Costs and Timelines

The pilot run gives you real-world data. This information helps you finalize the per-unit cost and the timeline for mass production. You can now calculate the actual production cost, which may differ from your initial estimates. The insights gained from this phase help you optimize the entire production process for maximum efficiency. This is the final step in evaluating readiness for mass manufacturing.

Phase 4: Scaling to Mass Production

You have validated your manufacturing process, and now you are ready for scaling to mass production. This phase focuses on the logistics and quality management required when you increase production from hundreds to thousands of units. Successful scaling depends on a well-managed production workflow. This is the final step in transitioning from prototype to mass production.

Managing Your Supply Chain

A reliable supply chain is the backbone of mass production. For successful scaling, you may consider working with multiple suppliers. This strategy offers several advantages for your production.

It builds resilience against unexpected disruptions.

It creates healthy competition for better pricing and terms.

It gives you access to new technologies and innovations.

It provides greater flexibility for delivery schedules.

This approach helps you maintain a steady flow of materials, which is essential for large-scale manufacturing and managing your overall cost.

Implementing Statistical Process Control (SPC)

Ensuring quality and consistency across thousands of units is a major challenge in scaling for mass production. This is where you implement Statistical Process Control (SPC).

📊 What is SPC? SPC is a method that uses statistical data to monitor and control your manufacturing process. You collect real-time data from the production line to track quality. This helps you detect and fix problems before they affect a large number of products.

This system of robust quality control ensures every collectible meets the high standard set by your prototype. It is a key part of the prototype to mass production journey.

Demand Forecasting and Inventory

Before you begin mass production, you must estimate how many units to create. For a new product, you can use qualitative forecasting methods. You can survey potential customers or get opinions from industry experts to gauge interest. Analyzing sales data from comparable products also provides valuable insight. This planning helps you avoid overproduction and manage inventory effectively, which is crucial for this stage of product development. This careful scaling helps you prepare a market-ready product.

Navigating Global Logistics

Getting your market-ready product to collectors worldwide involves complex logistics. You must navigate different international shipping regulations. You also need to prepare for seasonal demand spikes, like holidays, that can strain your production and delivery systems. Proper planning for these challenges is essential for a smooth time-to-market when scaling to mass production. This final part of the prototype to mass production process ensures your quality collectibles reach their new owners.

Phase 5: From Prototype to Mass Production Challenges

Even with careful planning, the journey from prototype to mass production presents challenges. Scaling your production requires you to anticipate and manage issues that can affect quality, cost, and timelines. Overcoming these hurdles is the final test of your production workflow.

Managing Tool Wear and Maintenance

Your production tools, especially molds, wear down over time. This wear can affect the quality of your collectibles. You must have a maintenance plan for your manufacturing tools. Regular cleaning and careful handling extend a mold's life, ensuring your production run remains consistent. The lifespan varies by material, which impacts your long-term production strategy.

Mold Type | Lifespan (Cycles) | Best For |

|---|---|---|

Two-Part Steel Mold | 5,000+ | Mass production |

Aluminum Mold | 1,000–3,000 | Mid-volume runs |

Silicone Mold | 50–200 | Prototyping, artist editions |

Ensuring Color and Finish Consistency

Maintaining uniform colors across thousands of units is a major challenge of scaling. Factories use specific techniques for ensuring quality and consistency.

Factory Techniques for Color Quality 🎨

Standard Systems: They use color systems like Pantone to create exact color matches for every batch.

Masterbatching: Concentrated pigments are mixed into the base resin in precise ratios for uniform color.

Sequential Painting: Workers paint one color on all units before moving to the next. This keeps color depth and application consistent.

These methods are vital for the final quality of your product during mass production.

Mitigating Supplier and Logistics Risks

Your production depends on a reliable supply chain. Delays can happen due to weather, port congestion, or other disruptions. You can mitigate these risks.

Diversify your suppliers to build resilience.

Maintain clear and constant communication with all partners.

Develop contingency plans for unexpected events.

Proactive planning helps protect your production schedule and keeps your scaling efforts on track.

Handling Defect Rates and Rework

A small flaw in a prototype can become a huge problem in mass production. You need a system for robust quality control to handle defects. Instead of just fixing broken items, you should focus on preventing errors. Use real-time data from the production line to spot issues early. When a defect occurs, perform a root cause analysis to find and fix the underlying problem. This approach improves overall quality and reduces waste, which is essential for successful scaling and manufacturing.

Your successful transition from prototype to mass production is not an accident. It is the result of a deliberate production workflow. Following the five phases of production—from design to mass production—is one of the best practices for a smooth transition. This structured approach helps you build trust through quality and achieve a seamless transition.

Success with a Structured Workflow 🏆

Luxury brands use this method for a sculpted shopper journey and high-quality production.

Accessory brands like Pura Vida leverage a structured production workflow for major revenue growth.

Invest in this process for transitioning from prototype to mass production. It protects your vision, ensures consistent quality, and manages cost for a successful production run.

FAQ

Why is DFM so important for my collectible?

Design for Manufacturability (DFM) aligns your creative vision with your factory's capabilities. You catch potential production problems early in the process. This step saves you significant time and money by preventing expensive design changes during mass production and ensuring a smoother workflow.

What happens if I skip the pilot production run?

Skipping a pilot run is very risky. You miss the chance to test your final tooling and assembly process at a small scale. This can lead to major quality issues, unexpected delays, and high defect rates during mass production, costing you much more later.

How many prototypes should I expect to make?

The number of prototypes varies for each project. You will likely create several versions to perfect the fit, form, and finish. This iterative process continues until you approve a final "Golden Sample" that meets all your quality standards for production.

Can one mold really make thousands of collectibles?

Yes, but you must use the right material for your mold.

A hardened steel mold is your best choice for mass production. It can produce thousands of units with high consistency. Softer molds, like silicone, wear out much faster and are better suited for prototypes or small, limited-edition runs.