Exploring the Versatility of Clear Plastic Cylinders in Modern Packaging: The Ultimate Guide

Introduction: Why Clear Plastic Cylinders Lead Packaging Innovation

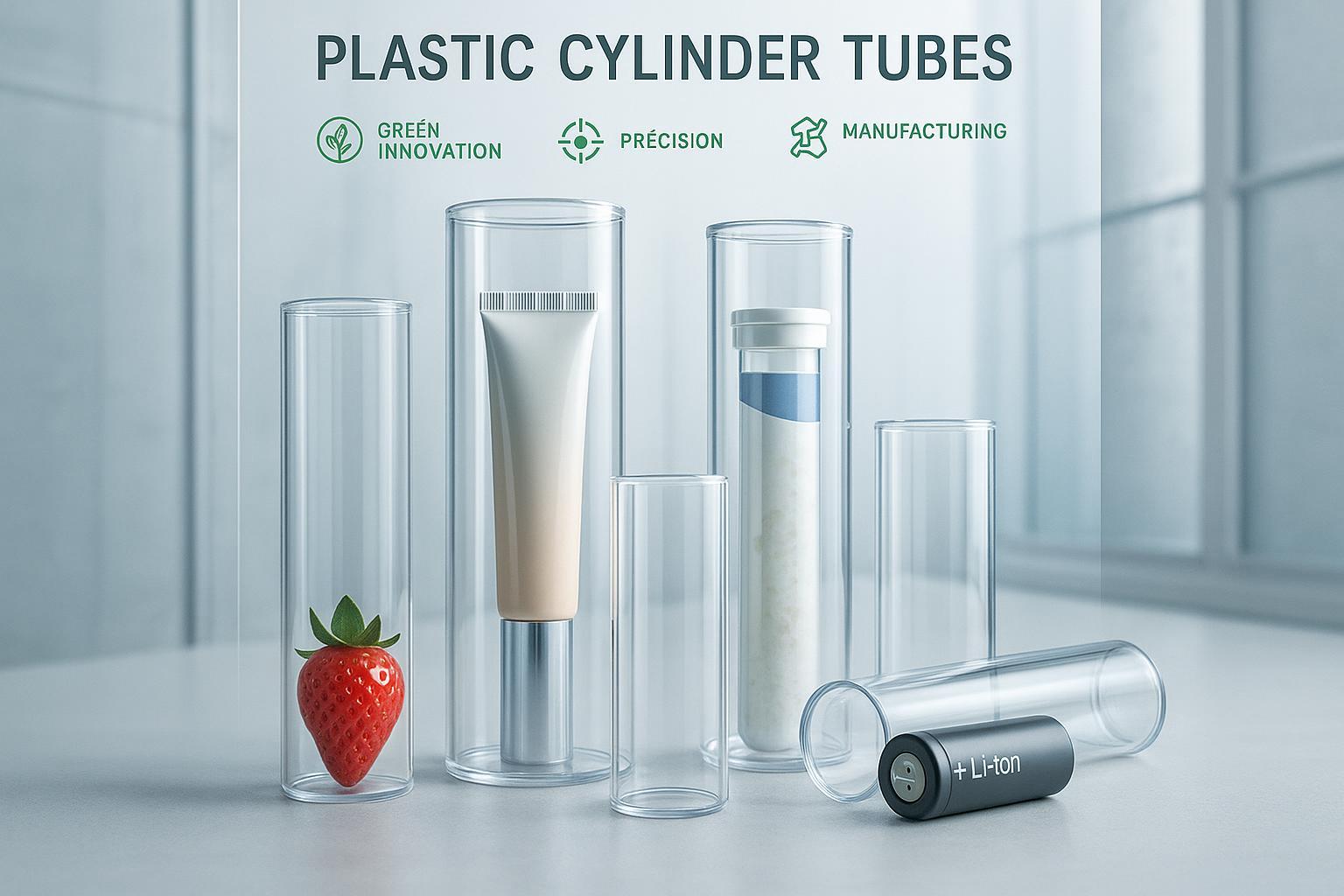

In a visually driven retail landscape, clear plastic cylinder packaging has emerged as a front-runner for brands seeking to blend product visibility, protection, and design flexibility. From cosmopolitan beauty counters to gourmet food aisles and sparkling tech gadgets, transparent cylinders grab attention while safeguarding contents. Modern options—especially those in acrylic, PET, and PETG—deliver customizable form, eco-friendly promise, and cost-effective performance tailored to diverse markets.

Did You Know? The global plastic packaging market is projected to exceed $616 billion by 2032, with clear cylinders experiencing rapid growth in beauty, food, gifting, and electronics (MarketsandMarkets).

Yet, businesses and designers are often confronted with challenges: which material suits my application, how do I ensure sustainability, what customization is truly possible, and how can supplier choices impact outcomes? This ultimate guide addresses these questions and more—backed by the expertise of Toyin Acrylic Products Co., Ltd. (TOYIN) and cutting-edge market intelligence.

1. Material Science & Manufacturing: Foundations of Transparency and Performance

1.1 Key Materials in Clear Cylinder Packaging

Material | Visual Clarity | Impact Strength | Food Safety | Recyclability | UV Resistance | Industry Notes |

|---|---|---|---|---|---|---|

Acrylic (PMMA) | ★★★★★ | ★★★★☆ | Yes | Yes (Code 7) | ★★★★★ | Luxurious look, rigid |

PET | ★★★★☆ | ★★★★☆ | Yes | Yes (Code 1) | ★★★★☆ | Widely used, cost-effective |

PETG | ★★★★☆ | ★★★★☆ | Yes | Yes | ★★★★☆ | Enhanced processability |

PVC | ★★★☆☆ | ★★★★☆ | Limited | Difficult | ★★★★☆ | Being phased out for eco/safety reasons |

PP/PS | ★★★☆☆ | ★★★☆☆ | Depends | Partial | ★★★☆☆ | Used for select closures/end caps |

Expert Tip: PET and PETG are quickly becoming industry standards for food and cosmetic packaging due to their clarity, safety, and recyclability. Acrylic stands out for high-end displays and premium branding.

Reference: Petro Packaging, VisiPak.

1.2 Manufacturing Processes

Extrusion: Continuous molten plastic is shaped into seamless tubes—ideal for PET/PETG and acrylic cylinders.

Thermoforming: Sheets are heated then shaped, useful for customized designs or adding specific features.

Injection Molding: Used for crafting end caps, lids, and intricate closure systems.

Precision Cutting & Assembly: Tubes are cut to bespoke lengths and joined with closures or bases for custom fits.

Surface Finishes & Printing: Branding can be applied via silk-screening, digital printing, hot stamping, or embossing.

TOYIN’s fully automated production line (ISO9001 certified) integrates all these steps, ensuring global-standard quality, rapid quoting, and unmatched customization (Learn more).

1.3 Comparative Performance: Why Material Choice Matters

Acrylic: Supreme clarity, premium gloss, strong UV blocking, best for luxury, retail, trophies.

PET/PETG: Balanced clarity, cost, and environmental performance—go-to for beauty, food, and health industries.

PVC: Once dominant, now restricted due to recyclability and regulatory issues; not recommended for food/cosmetics.

Reference: Packaging.vip

2. Design Versatility & Customization: Unlocking Creative and Functional Freedom

2.1 Form Factors & Dimensions

Cylinder sizes: From mini vials (under 10mm diameter) to large tubes (over 400mm length for retail & industrial products).

Wall thickness: Tailored for durability or cost-savings (‘lightweighting’ trend).

Open/closed bases, hanging holes, fitments: Adaptable for display, dispensing, or secure packaging.

2.2 Custom Closure & Sealing Systems

Snap-fits, screw-on, friction-fit, tamper-evident, heat-sealable closures.

Variety of end cap materials: plastic (PP, PS), aluminum, cork, or wood—enabling full brand alignment.

2.3 Branding & Decoration Possibilities

Printing: Silk screen, digital UV, hot stamping, or embossing for powerful shelf presence.

In-mold labeling: Permanent branding within the packaging wall.

Window cutouts or colored accents: Add hierarchy, direct consumer attention, or accentuate brand identity.

2.4 Downloadable Customization Brief

Download Your Custom Cylinder Design Checklist (PDF)

2.5 Prototyping & MOQ

Rapid prototyping with 3D design and in-house model shop.

Flexible minimum order quantities (MOQs) enable both boutique runs and mass production.

3. Application Insights: How Industries Leverage Clear Cylinder Packaging

Clear tubes empower brands to showcase products with confidence and differentiate in crowded marketplaces. Key sectors include:

3.1 Cosmetics & Personal Care

Use Cases: Lip balms, serums, bath pearls, gift sets.

High clarity for vibrant product colors.

Airtight closures preserve freshness.

Decorative elements (foil, debossing) amplify shelf impact.

Case Example: Premium skincare brand harnessed TOYIN’s custom color and silk-screening to create limited-edition packaging for a holiday launch, boosting sales by 38% (brand identity withheld under NDA).

3.2 Food & Confectionery

Use Cases: Candies, chocolates, teas, spices.

Food-grade PET cylinders ensure compliance and recyclability.

Custom fitments secure delicate items like macarons.

Industry Insight: Jelly Belly’s PET tubes (by VisiPak) are a classic reference for clarity, custom branding, and freshness retention.

3.3 Electronics & Hardware

Use Cases: USB drives, cables, connectors, display items.

Antistatic or impact-resistant options for sensitive components.

Custom foam/protective inserts.

3.4 Gifting & Retail Branding

Cylinders for promotional sets, holiday specials, luxury corporate gifting.

3.5 Medical & Lab Supplies

Sterile tubes for sampling kits or devices (compatible with ISO 13485 workflows at advanced suppliers).

TOYIN Real Case: Custom acrylic tubes as functional trophies—used by a luxury watch brand to elevate event merchandising—demonstrate the merger of packaging and branded keepsake in high-value contexts.

3.6 Visual Application Gallery

4. Sustainability & Green Packaging: Towards a Circular Future

4.1 Life Cycle and Environmental Impact

Material Choices: PET & PETG support closed-loop recycling (Code 1 plastics). Recycled PET (rPET) can deliver up to 50% lower GHG emissions compared to virgin (APR Design Guide).

Acrylic: Recyclable, and advanced processes now reclaim PMMA at industrial scale.

4.2 Regulatory & Compliance Trends

Global Push: EU EPR, US/EU recycled content mandates—brands must demonstrate circularity.

Food Safety: Suppliers should comply with FDA, EFSA and ISO9001 standards.

4.3 Green Manufacturing at TOYIN

Toyin Acrylic Products Co., Ltd. utilizes precision cutting and optimized heating, minimizing scrap, and recycles production offcuts. Their facilities are ISO9001 certified with a strict eco-compliance focus. Brands can request certification for LEED projects or environmental audits.

4.4 Eco-Innovation Checklist

Choose Code 1 PET/rPET for best recycling rates.

Request supplier environmental credentials and LCA data.

Prioritize single-material designs (‘mono-material’) for easy post-use recycling.

Download: Supplier Sustainability Self-Check Template (PDF)

5. Cost, Sourcing & Buyer Tools: Maximizing Value and Reducing Risk

5.1 Total Cost Factors

Factor | Impact Level | Notes |

|---|---|---|

Raw Material | High | PET/PETG generally lower cost than acrylic (but acrylic = premium) |

Customization | Medium/High | Decoration, complex closures, or unique profiles add cost |

MOQs | Variable | Small runs may mean higher per-unit costs |

Compliance | Medium | Certifications (FDA/ISO) may cost more but vital in food/cosmetics |

Logistics | Variable | Global shipping affects lead times and pricing |

5.2 Supplier Evaluation & Qualification

Certifications: ISO9001, FDA, food safety, green compliance

Reputation: Look for global fulfillment experience and track record of quality, like TOYIN’s project portfolio

Customization Depth: Rapid design/engineering support, digital prototyping, end-to-end service

Lead Time: TOYIN offers rapid quoting and global delivery via optimized logistics

Download Your Supplier Evaluation Checklist (PDF)

5.3 Avoiding Common Pitfalls

Closure/material mismatch (e.g., non-food safe finishes)

Overlooking food safety or recycling codes

Ignoring minimum order quantities or lead times

Failing to demand proof of compliance and past project outcomes

5.4 Get a Custom Quote or Design Consultation

Ready to innovate your packaging? Request a custom quote or free design session with TOYIN.

6. Future Trends: Technologies and Consumer Demands Shaping the Sector

6.1 Sustainable Materials and Bioplastics

Expansion of post-consumer recycled PET (PCR-PET)

Experimental use of biodegradable plastics for single-use or special applications

6.2 Digital and Smart Packaging

Direct-to-object digital printing for variable data, QR codes, connected packaging

Integration with RFID/NFC for traceability and consumer engagement

6.3 Rapid Prototyping and Personalization

3D printing for design sampling

Short lead times with global fulfillment

6.4 Regulatory Landscape

Tighter bans on PVC in food/cosmetics (EU, US)

EPR and recycled content mandates are rising in Asia & globally

Reference: Packaging World, SpecialChem

7. Integrating TOYIN Solutions: Real-World Excellence in Acrylic Cylinder Packaging

7.1 About TOYIN Acrylic Products Co., Ltd.

Founded in 2000 and headquartered in Dongguan, China, TOYIN Acrylic Products Co., Ltd. is a global leader in the design, R&D, production, and sales of custom acrylic packaging. With an 11,500 m² facility, ISO9001 certification, and a 150-strong expert team, TOYIN serves major brands worldwide with:

Full-spectrum manufacturing (cutting, thermoforming, assembly, finishing)

Market-leading quality assurance

Rapid prototyping, digital sampling

Global logistics and fulfillment

Eco-friendly, compliant, and innovative solutions

7.2 Case Studies

Cosmetics: Limited-Edition Cylinder for Luxury Skincare

Delivered a bespoke printed acrylic cylinder for a luxury skincare brand—combining custom colors, foil embossing, and airtight fitment. Result: Standout retail shelf presence, 38% sales uplift.

Food: PET Cylinder for Gourmet Chocolates

Produced lightweight PET tubes with slip-fit, food-contact safe ends for an international confectioner. Achieved longer shelf life and premium gifting experience, fully recyclable.

Electronics: Custom End-Capped Protective Tubes

Supplied anti-static acrylic tubes for electronics exporters—protecting products in shipment and acting as display packaging in-store.

For details and more case studies: TOYIN Project Portfolio

7.3 Why Partner with TOYIN?

Bespoke Innovation: Custom shapes, closures, finishes for every project.

Green Commitment: Advanced recycling, resource efficiency, and compliance.

Rapid Response: Fast quoting, prototyping, and shipping to 100+ countries.

Proven Reliability: Trusted by brands across luxury, retail, electronics, food, and more.

Book Your Free Design Consultation

FAQs & Download Center: Practical Resources for Designers and Buyers

Q: How do I choose between PET and acrylic for my packaging?

PET is ideal for food/cosmetics and high-volume runs due to cost, recyclability, and food safety. Acrylic delivers premium look, outstanding clarity, and tactile appeal—best for high-end/luxury or decorative use.

Q: Can I order small quantities for pilot tests?

Yes. TOYIN supports flexible MOQs and rapid digital prototyping. Request details.

Q: What eco-certifications can TOYIN provide?

ISO9001, material LCA, food-contact compliance, and environmental audit documents are available on request.

Q: How quickly can my order be delivered globally?

With TOYIN’s advanced workflows and global logistics, most projects ship within 7-21 working days from approval.

Download Center

Conclusion & Next Steps

Clear plastic cylinder packaging stands at the intersection of visibility, protection, sustainability, and design innovation. With advanced materials, custom manufacturing, and eco-positive practices—championed by leaders like TOYIN—brands can elevate both product and perception on the global stage.

Ready to create standout packaging for your next product launch?

Get Your Free Custom Quote and Expert Consultation Now »