2025 Bulk Order Guide QC & Payment Tips

You can secure your bulk mobile orders with one proven method. It combines a 30/70 payment structure with strict quality control (QC) and a clear Acceptable Quality Limit (AQL) standard.

This professional framework protects your capital. You confirm product quality before releasing the final payment.

This bulk order guide shows how this approach minimizes financial risk. It ensures your 2025 inventory is profitable from the start. You gain control over your sourcing process.

Your Bulk Order Guide to Smart Payment Terms

You must protect your capital when placing large orders. Smart payment terms are your first line of defense against financial risk. This section of the bulk order guide breaks down the best payment structures to secure your inventory.

The 30/70 Payment Split

The 30/70 payment split is the industry standard for a reason. You pay a 30% deposit to start production and the remaining 70% only after the goods pass your quality control (QC) inspection. This structure creates a fair balance. It protects both you and your supplier from common financial risks.

This balanced approach ensures suppliers have the funds to begin production while you retain leverage to guarantee quality.

| Party | Primary Financial Risk | How 30/70 Model Balances Risk |

|---|---|---|

| Suppliers (Exporters) | Non-payment after starting production. | The 30% deposit covers initial material and labor costs, showing your commitment. |

| You (Importers) | Paying for goods that are defective or not delivered. | You withhold the 70% final payment until you verify the products meet your standards. |

Alternative Payment Structures

While 30/70 is common, other terms may suit your specific situation.

-

50/50 Split: You pay 50% upfront and 50% upon completion. This term places more risk on you, as a larger portion of your capital is tied up before you verify quality. It is often requested by suppliers for custom or high-value orders.

-

Letter of Credit (L/C): For very large or high-risk international orders, you can use an L/C. This is a guarantee from a bank that the supplier will receive payment once they meet specific conditions. An L/C provides excellent security, especially when you are working with a new supplier or in a high-risk market.

- Security for Both Parties: It assures you of receiving goods and assures sellers of payment.

- Risk Mitigation: It reduces risks like non-payment or disputes over product quality.

- Payment Assurance: Sellers can ship goods confidently, knowing a bank guarantees payment.

-

Escrow Services: You can use a trusted third-party service like Escrow.com to hold your payment. The service releases the funds to the supplier only after you confirm you have received and approved the goods. These platforms simplify international transactions by handling currency exchange and adhering to global compliance standards.

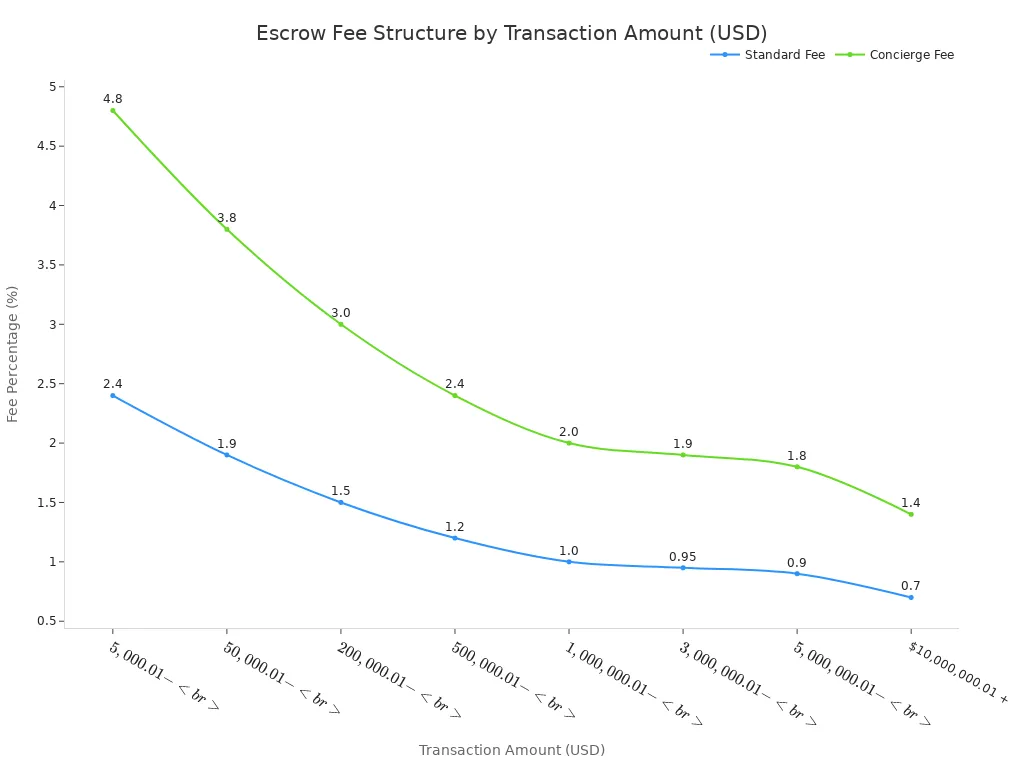

Tip: Escrow fees are typically based on the transaction value. Fees decrease as the order value increases, making it a cost-effective option for large purchases.

Image Source: statics.mylandingpages.co Here is a sample fee structure for merchandise transactions in USD:

Transaction Amount Standard Fee $5,000.01 - $50,000.00 2.4% ($130.00 minimum) $50,000.01 - $200,000.00 1.9% ($1,200.00 minimum) $200,000.01 - $500,000.00 1.5% ($3,800.00 minimum) Over $500,000.01 1.2% or less

Key Purchase Agreement Clauses

Your payment terms are only as strong as your written agreement. You must include clear, legally binding clauses in your Purchase Agreement (PA) to protect your interests. This is a critical part of any professional bulk order guide.

Your PA should clearly define the following:

- Clear Payment Triggers: State exactly what event triggers the final payment. The best trigger is

“Passing a third-party QC inspection based on agreed AQL standards.” - Delay Penalties: Define penalties for late production or shipping. You and your supplier must agree on these terms before signing.

- A common penalty is a percentage of the order value. For example, you could charge 3% for a one-week delay.

- Another option is making the supplier cover expedited shipping costs (like air freight) if a delay exceeds a certain period, such as two weeks.

- Currency Agreement: Specify the transaction currency (e.g., USD, EUR) to avoid disputes caused by exchange rate fluctuations.

- Jurisdiction: Agree on the governing law and jurisdiction for resolving any disputes. Reputable suppliers, like Chicago Tech, Inc., are transparent about these terms.

- Minimum Order Quantities (MOQs): Discuss how your order volume and MOQ affect payment terms. Larger, consistent orders may give you the leverage to negotiate more favorable terms.

Always get every detail in writing. A verbal agreement is not enforceable. Your Purchase Agreement is your ultimate tool for holding your supplier accountable.

Essential QC Checkpoints for Phones & Accessories

After you secure your payment terms, your next focus is the product itself. Rigorous Quality Control (QC) is not optional. It is the mechanism that triggers your final payment and guarantees the value of your inventory. A detailed inspection process ensures every unit you receive meets the exact standards you defined in your Purchase Agreement.

QC for Smartphones & Tablets

You must inspect every critical aspect of smartphones and tablets. A systematic checklist prevents costly mistakes and ensures consistency across your entire order.

1. Cosmetic Inspection This check assesses the physical appearance of the device. For used or refurbished phones, you must define and agree upon a clear grading system with your supplier.

A refurbished grade is a quality classification based on cosmetic condition. The standard system ranges from Grade A (best) to Grade C (lowest), helping you set clear expectations. Some suppliers use terms like "Pristine" or "Excellent" instead.

- Grade A: The device looks like new. It has no visible scratches or scuffs.

- Grade B: The device shows light wear, such as minor scuffs or faint scratches.

- Grade C: The device has clear signs of use, including noticeable scratches and dents.

2. Functional Testing This is the most critical part of your QC process. You must verify that every component works as intended.

| Component | Key Checks |

|---|---|

| Screen | Check for dead pixels, discoloration, touch responsiveness, and cracks. |

| Cameras | Test both front and rear cameras for focus, image quality, and flash function. |

| Ports | Verify charging port, headphone jack, and data transfer capabilities. |

| Buttons | Ensure all physical buttons (power, volume, home) are responsive. |

| Audio | Test speakers, microphones, and earpiece for clarity and volume. |

3. Connectivity and Software You need to confirm the device connects properly and runs stable software. You can use specialized diagnostic tools for these tests.

- Use software like MobiTEST or M360soft to run comprehensive connectivity tests.

- Verify Wi-Fi, Bluetooth, and GPS functionality.

- For cellular tests, use tools like BitRaser to confirm SIM card detection and network registration.

- Check the OS version and ensure there is no carrier lock or user account lock (iCloud/Google).

4. Battery Health A weak battery is a common point of failure. You must set a minimum standard, especially for refurbished devices.

- For refurbished iPhones, you should require a minimum battery health of 85%. Apple itself considers anything below 80% to be degraded.

- This 85% standard is also a good benchmark for refurbished Android devices.

- Confirm that the battery charges correctly and does not drain unusually fast.

QC for Accessories

Accessories are just as important as the devices they support. Poor quality accessories can damage a device and your brand's reputation.

Cables (USB, Lightning)

- Visual Check: Inspect for frays, poor molding, and loose connectors.

- Functional Test: Confirm the cable charges a device and transfers data correctly.

- Bend Test: A formal bend test ensures durability. In a lab setting, a machine rocks the cable back and forth to simulate use. The cable must withstand this motion without showing damage or stiffness. A simpler manual test involves flexing the cable's stress points near the connector to check for weakness.

Chargers (Wall Adapters)

- Power Output Verification: You must verify that the charger delivers the advertised voltage and amperage. Use a

USB fast charging protocol testerto measure the actual output and confirm it meets specifications. - Safety Check: Inspect for proper construction and regulatory marks. Overheating during a brief test is a major red flag.

Cases

- Fit and Finish: The case must fit the phone model perfectly. Check for precise cutouts that align with all ports, cameras, and buttons.

- Button Responsiveness: Ensure the case's buttons are easy to press and provide good tactile feedback.

- Material Quality: The material should feel durable and provide adequate grip. Poor quality materials can fail to absorb shock or may become brittle over time.

Packaging and Labeling Inspection

Your product’s packaging is the first thing your customers see. It also plays a critical role in logistics and compliance. Errors here can lead to major problems.

1. Barcodes and Serial Numbers Incorrect or unreadable labels can halt your entire shipment.

- Scanning Test: Scan a sample of barcodes and QR codes to ensure they are readable.

- Data Match: Verify that the serial number on the box matches the serial number on the device.

Warning: Faulty barcodes can lead to severe consequences. Retailers may issue chargebacks of 15-20% of the shipment's value, and you could face financial penalties for each unreadable label.

2. Regulatory Marks Your products must display the correct compliance marks for the target market. Missing marks can result in your shipment being seized by customs.

- FCC Mark: Required for all electronics sold in the United States.

- CE Mark: Mandatory for most electronics sold in the European Union.

- UKCA Mark: Required for products sold in Great Britain (England, Scotland, and Wales).

3. Package Integrity The packaging must protect the product during transit. You can specify industry-standard tests to verify its durability.

- Visual Inspection: Check for dents, water damage, or poorly sealed boxes.

- Transit Simulation Tests: For large or fragile shipments, you can request tests based on International Safe Transit Association (ISTA) standards. Procedures like ISTA 3B (for LTL shipments) or ISTA 1D (for packages over 150 lbs) simulate the drops, vibrations, and impacts that occur during shipping.

Applying AQL for Consistent Quality

You have your QC checklists ready. Now, you need a system to apply them efficiently. This is where the Acceptable Quality Limit (AQL) becomes your most powerful tool for ensuring consistent quality across thousands of units without inspecting every single one.

What Is AQL?

AQL is an internationally recognized statistical method used for product inspections. The formal standard, ISO 2859-1, defines AQL as the "quality level that is the worst tolerable." In simple terms, it is the maximum number of defective units you will accept in a batch.

AQL allows you to inspect a smaller, random sample of your order instead of the entire shipment. This saves you significant time and money while still giving you a reliable snapshot of the overall product quality. You can make objective, data-driven decisions to accept or reject a batch.

Defining AQL Standards

You must define your AQL standards before production begins. You do this by classifying defects into three levels of severity.

- Critical Defects (AQL 0): These defects pose a safety hazard. You should have zero tolerance for them. A real-world example was the Samsung Note 7 battery flaw, which created a fire risk.

- Major Defects (AQL 1.5): These defects make the product unusable and would lead to customer returns. A non-functional camera is a classic major defect.

- Minor Defects (AQL 2.5): These are small cosmetic issues that do not affect the product's function, like a small scratch on the phone's body.

Here is a common AQL setup you can use:

| Defect Type | Description | Recommended AQL |

|---|---|---|

| Critical | Poses a safety risk to the user. | 0% |

| Major | Affects the core function of the product. | 1.5% |

| Minor | A small cosmetic flaw. | 2.5% |

Communicating AQL to Suppliers

Your AQL standards are only effective if your supplier understands and agrees to them. You must formalize these expectations in writing before you pay your deposit.

Follow these steps to align with your supplier:

- Specify AQL in Your Contract: Clearly state the AQL levels for Critical, Major, and Minor defects in your Purchase Agreement.

- Provide Detailed Checklists: Share your QC inspection checklists with the factory. This ensures everyone uses the same criteria to classify defects.

- Define Corrective Actions: Outline what happens if a batch fails inspection. This could include rework, a price reduction, or remanufacturing the order.

Clear communication and documentation are key. When your supplier knows exactly how you will measure quality, you minimize misunderstandings and protect your investment.

You can master your 2025 sourcing with a clear action plan. This bulk order guide provides a framework for secure and profitable inventory management. Success hinges on a proactive, data-driven strategy.

Follow these three steps for every order:

- Secure Your Capital: Implement a 30/70 payment term tied directly to QC results.

- Verify Product Quality: Use detailed QC checklists for every inspection.

- Set Clear Expectations: Define and contractually agree on your AQL standards before production.

This structured approach, a cornerstone of any modern bulk order guide, builds supply chain resilience and prepares you for a dynamic market.

FAQ

What if a supplier rejects the 30/70 payment term?

You can negotiate for alternative terms. Propose using a Letter of Credit (L/C) for large orders or a trusted Escrow service. These options provide strong security for both you and the supplier, making them excellent compromises when you reach a deadlock on standard payment splits.

How do I find a reliable third-party QC inspector?

You can find reputable inspection companies through online directories like QIMA or Intertek. Always vet potential partners. You should request sample inspection reports and check their client reviews. This helps you confirm their expertise in electronics and their attention to detail before you hire them.

Can I set a 0% AQL for all defects?

You should only set a 0% AQL for critical defects that pose a safety risk. Applying it to major or minor defects is impractical and costly. Suppliers will likely reject such strict terms or increase prices significantly, as flawless mass production is nearly impossible.

What is the most important document in a bulk order?

Your Purchase Agreement (PA) is the most critical document. It legally binds your supplier to all agreed-upon terms. This includes your payment structure, QC checklists, AQL standards, and delivery schedule. A strong PA is your ultimate tool for enforcement and protection.