Mastering Bulk Orders A Guide for 2025

Your museum, gallery, or lab faces significant financial and quality risks with every large-volume purchase. This bulk order guide provides a clear path to success. You can transform uncertainty into control and protect your institution's investment.

Success in 2025 depends on mastering three key areas:

- Negotiating secure payment terms.

- Implementing robust quality control.

- Defining clear quality standards.

This approach gives you a blueprint to place every order with complete confidence.

Your Bulk Order Guide to Payment Terms

Your payment terms are your first line of defense against financial risk. You want to avoid paying for an entire order before you can verify its quality. The supplier, however, needs funds to cover production costs. This section of our bulk order guide helps you find the right balance.

Common Payment Structures

You will encounter several common payment structures. Each one distributes risk differently between you and the supplier. Understanding these options is key to protecting your institution's funds.

| Payment Term | How It Works | Buyer's Risk Level |

|---|---|---|

| 100% Upfront | You pay the full amount before production begins. | 🔴 High |

| 50/50 | You pay 50% upfront and 50% upon shipment or delivery. | 🟡 Medium |

| 30/70 | You pay a 30% deposit and the final 70% before shipment. | 🟢 Low-Medium |

| Net 30/60 | You pay the full amount 30 or 60 days after receiving the goods. | ✅ Very Low |

While Net 30/60 terms are ideal for your cash flow, they are rare for initial orders. A 30/70 or 50/50 split is a more realistic and balanced starting point for negotiations.

Negotiation Strategies

Use your position to secure favorable terms. Strong negotiation protects your budget and ensures supplier accountability. This bulk order guide recommends three powerful tactics.

-

Leverage Your Reputation: Museums, galleries, and labs are stable, reputable clients. Remind suppliers of your institution's credibility and the potential for a long-term partnership. This can help you secure better terms than a typical commercial business might receive.

-

Tie Payments to Quality: Make payments conditional on successful quality control (QC) approvals. For example, you can structure the contract so the final 70% payment is only released after the goods pass a pre-shipment inspection. This powerfully motivates the supplier to meet your standards.

-

Use a Letter of Credit (L/C): For large or international orders, an L/C is an excellent tool. It is a guarantee from your bank to the supplier's bank. The bank only releases your payment when the supplier provides proof of shipment and meets all contract terms. It provides maximum security for both you and the supplier.

Pro Tip: Always document your agreed-upon payment terms in a formal contract before production starts. This simple step prevents future misunderstandings.

Implementing QC Checkpoints

Effective quality control (QC) protects your investment and your institution's reputation. A small investment in inspections can save you from receiving an entire shipment of unusable goods, delivering an exceptionally high return. By implementing checks at key production stages, you catch problems early, reduce waste, and ensure the final product meets your exact standards.

The 3 Critical QC Stages

A multi-stage inspection process gives you maximum control over your order. You can identify and correct issues before they become costly mistakes. Schedule inspections at these three critical points:

- Pre-Production Check (PPC): This first check happens before mass production begins. It confirms your supplier has sourced the correct raw materials, components, and colors. This step prevents fundamental errors from ever entering the production line.

- During Production Check (DUPRO): An inspector visits the factory when 10-20% of your order is complete. They examine the first finished products for defects and check workmanship quality. A DUPRO confirms that production is on schedule and allows for course corrections, saving the entire batch from potential flaws.

- Pre-Shipment Inspection (PSI): This is your final review, conducted when at least 80% of the order is produced and packaged. An inspector randomly samples products to verify quality, quantity, labeling, and packaging against your specifications. A successful PSI gives you the confidence to approve the final payment and shipment.

Building a QC Checklist

A detailed QC checklist removes ambiguity and gives your supplier objective criteria for success. Your checklist should be a core part of your manufacturing agreement. Tailor it to your product's specific needs.

Checklist Examples for Your Institution:

For Museums & Galleries:

- ✅ Color Accuracy: Does the print on the tote bag perfectly match the specified

Pantone 18-1663"Fiesta" red?- ✅ Material Finish: Is the finish on the custom frame smooth and free of scratches or blemishes?

- ✅ Packaging Integrity: Does the individual product box protect the item from damage during shipping?

For Education & Labs:

- ✅ Functional Testing: Does the circuit board kit power on and function as designed?

- ✅ Material Safety: Do all plastic components comply with safety standards like

ASTM F963for non-toxic materials?- ✅ Assembly Accuracy: Are all parts of the model skeleton correctly assembled and securely attached?

Defining Quality with AQL

Your QC inspections need a clear pass/fail system. This is where the Acceptable Quality Limit (AQL) becomes essential. AQL is a statistical method that defines the maximum number of defective items you will accept in a batch. It does not mean you want defects. Instead, as defined by the ISO 2859-1 standard, it is the "worst tolerable" quality level you will permit before rejecting an entire order.

Understanding AQL Basics

AQL works by classifying defects into three categories. This helps you prioritize what matters most. You will have zero tolerance for issues that pose a safety risk.

| Defect Type | Definition | Example for Your Institution |

|---|---|---|

| 😱 Critical | A defect that could harm a user. | A sharp edge on a children's science kit toy. |

| 😠 Major | A defect that makes the product unusable or likely to be returned. | A museum catalog with blurry, unreadable text. |

| 🤔 Minor | A small issue that does not affect the product's use. | A tiny scratch on the bottom of a lab beaker. |

An inspector does not check every single item. Instead, they use AQL tables to perform a random sample inspection. The process is simple:

- Find Your Sample Size: Based on your total order quantity, an AQL table provides a "code letter."

- Find Your Limits: This code letter then tells you how many units to inspect and the maximum number of Major or Minor defects allowed. If the sample fails, you can reject the whole shipment.

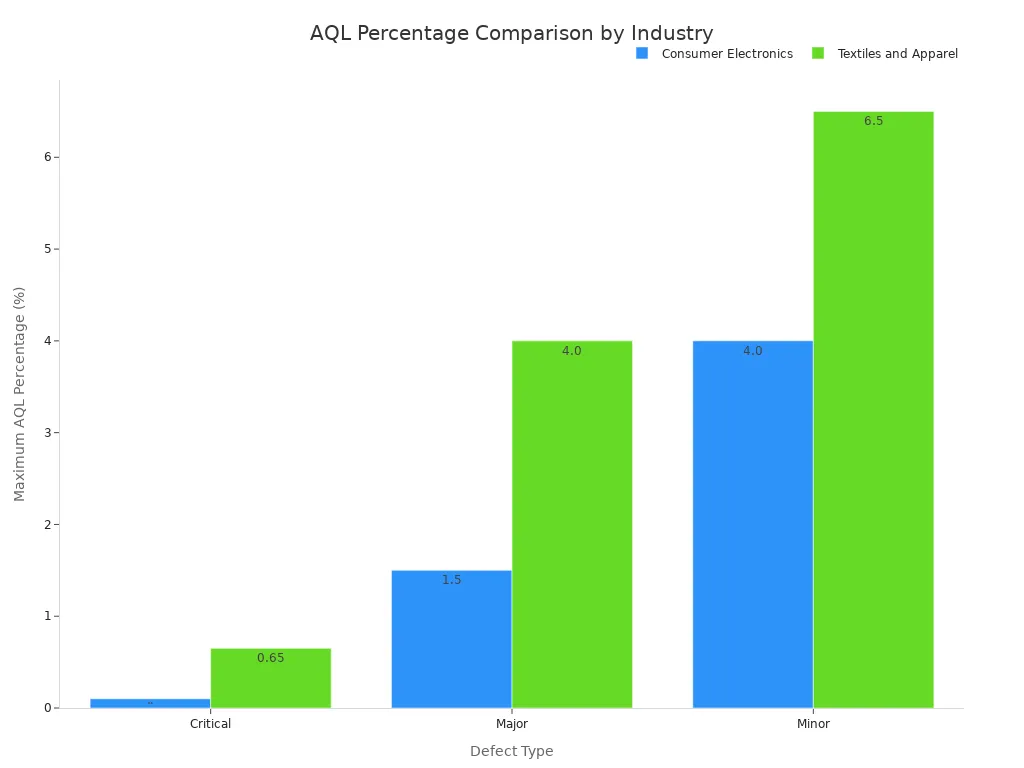

Setting Your AQL Standards

You and your supplier must agree on AQL standards before production begins. A common starting point for consumer goods is:

0% Critical Defects, 2.5% Major Defects, and 4.0% Minor Defects

This means you will not accept any critical defects. You will accept a maximum of 2.5% major defects and 4.0% minor defects in the sample. High-end institutions often set stricter limits. For example, a luxury brand might set a 1.5% limit for major visual defects to protect its premium image.

Different industries also have different standards. As the chart below shows, textiles often have higher AQL percentages than electronics.

Key Action: Your AQL levels are not just a guideline; they are a contractual requirement. Formally document your AQL for each defect type in your purchase agreement. This makes your quality standard an enforceable part of your deal.

This bulk order guide gives you a clear framework for success. Before your next purchase, use this final checklist to protect your institution and ensure supplier accountability.

Your Final Checklist:

- Secure Payments: Negotiate payment terms tied directly to successful QC milestones.

- Schedule Inspections: Arrange for checks at pre-production, during production, and pre-shipment.

- Define Quality: Contractually document your AQL standards to create an objective, enforceable quality benchmark.

Following this bulk order guide transforms purchasing from a financial risk into a strategic advantage.

FAQ

What if a supplier rejects my payment term proposal?

You should see this as a potential red flag. A good supplier is usually willing to negotiate. If they demand 100% upfront payment with no flexibility, you should consider finding a different partner. Your financial security is a top priority.

Can I perform the QC inspections myself?

Yes, you can conduct inspections yourself to save money. However, a professional third-party inspector provides an unbiased, expert report. This gives you stronger leverage if you find any quality issues. The choice depends on your budget and the order's complexity.

What happens if an order fails its final inspection?

Your contract gives you power. You can reject the entire shipment and refuse to make the final payment. You can also ask the supplier to rework the defective products at their own cost. This is why tying payments to QC is so important.

Should I use the same AQL for all my products?

No, you should adjust your AQL standards based on the product. A high-value item for a gallery exhibit needs a much stricter AQL (fewer defects allowed) than a simple promotional giveaway item.

Pro Tip: Always set stricter AQL levels for defects that affect product function or safety.

See Also

An Easy-to-Follow Guide for Large Collectible Orders

Mastering Worldwide Collectible Launches: Your Comprehensive Strategy Playbook

The Definitive 2025 Handbook for Custom Acrylic Display Solutions

Optimizing Collectible Manufacturing: Enhancing Your Production Process Efficiency

Essential Visual Merchandising Strategies for Displaying Collectible Figures