The Ultimate Bulk Order Guide for Food Chains

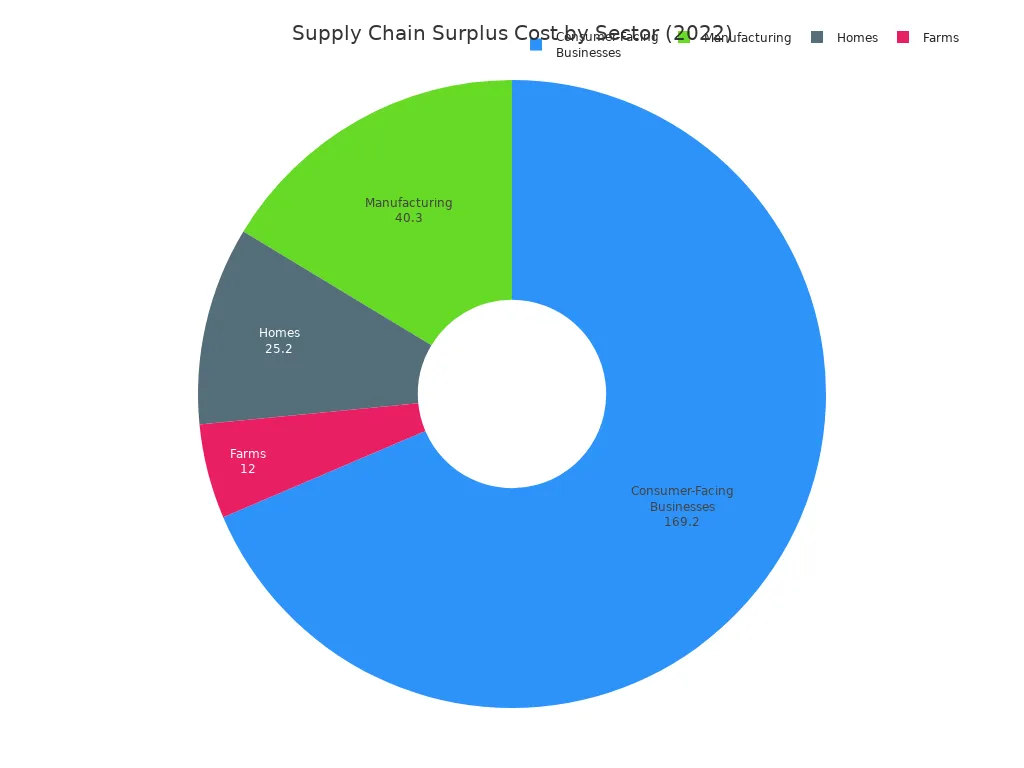

You face a core challenge in the food and retail industry. You must manage large-scale purchasing to control costs. Maintaining food quality across all locations is essential. Food service businesses often bear the largest financial burden from supply chain waste.

This bulk order guide provides a framework for control. It integrates financial strategy, quality control, and objective acceptance criteria.

Key Areas for Strategic Control:

- Sourcing & Suppliers: Your sourcing must secure quality food and quality packaging from all suppliers.

- Quality Control & Compliance: Uphold food quality and regulatory compliance through strict quality control.

- Packaging & Sourcing: Verify packaging quality and sourcing compliance from your suppliers.

- Regulatory & Suppliers: Manage regulatory rules with suppliers for full compliance on all food and packaging.

A Practical Bulk Order Guide Framework

You need a strong framework to manage your purchasing. This bulk order guide connects your financial strategy with your operational standards. It creates a system for total control over your supply chain.

Integrating Payments, QC, and AQL

Your payment, quality control, and acceptance processes should work together. You can tie payments directly to quality approvals. This practice holds your suppliers accountable for the quality of their food and packaging. You define your requirements for food and packaging before production begins. This gives you clear grounds for accepting or rejecting a shipment.

A digital system helps manage this integration. It provides a central place for tracking raw materials, ensuring food safety, and managing regulatory compliance. This improves your sourcing and logistics. You gain better visibility and control over your entire operation. This integrated approach ensures compliance and protects your brand's quality standards.

Key Steps for Supplier Accountability

- Find suitable suppliers for your needs.

- Define your quality requirements upfront.

- Use regular quality inspections to verify compliance.

- Connect payments to successful quality checks.

Leveraging Volume for Discounts and Rebates

Your purchasing volume is a powerful negotiation tool. You can use strategic sourcing to secure better prices from suppliers. A large, consistent order allows suppliers to plan their production efficiently. This often translates into cost savings for you. Your goal is to improve supplier reliability while reducing costs.

Different business models require different sourcing strategies.

- The Continuous Flow Model works well for high-demand food items. It ensures a stable supply of raw materials and packaging.

- The Efficient Chain Model helps you compete on price. It focuses on efficient logistics and inventory management to lower costs.

Effective sourcing requires careful management of regulatory rules with suppliers. You must ensure full compliance on all food and packaging to maintain quality and avoid penalties. This control over your sourcing process is a core part of this bulk order guide.

Smart Payment Terms and Cost Control

You must manage payment terms to maintain healthy cash flow and exercise financial control. Smart payment strategies protect your capital. They also hold your suppliers accountable for the quality of their food and packaging. Your sourcing approach directly impacts your negotiation power.

Common Payment Models

You can choose from several payment models. Each offers different levels of risk and security for you and your suppliers. Selecting the right model depends on your relationship with the vendor, order value, and the specific food products involved. For example, a Letter of Credit provides security for high-value international sourcing, while a 50/50 split can work with trusted partners.

| Payment Model | Best For | Key Consideration |

|---|---|---|

| Advance Payment | New suppliers or custom orders | High risk for you; no leverage if quality issues arise. |

| Net 30/60/90 | Established relationships | Improves your cash flow; standard for domestic sourcing. |

| 50/50 Split | Balancing risk with trusted suppliers | Motivates suppliers to meet quality and timeline commitments. |

| Letter of Credit (L/C) | High-value international orders | Offers strong security but involves complex bank procedures. |

Negotiating Favorable Terms

Your negotiations should aim to link payments directly to performance. This gives you critical control over your supply chain. Extending payment terms by just a few days can unlock significant working capital. You should make payment releases conditional on successful quality control inspections. This ensures compliance with your standards for both food and packaging.

Key Negotiation Tactics 💡

- Link Payments to QC: Release funds only after goods pass inspection. This ensures quality and regulatory compliance.

- Define Penalty Clauses: Your contracts should specify consequences for suppliers who fail quality checks. This protects you from losses.

- Leverage Volume: Use your strategic sourcing power to ask for better terms and achieve greater supplier reliability.

- Offer Early Payment Discounts: You can negotiate a discount from a vendor for paying an invoice early.

Effective negotiation improves your logistics and financial stability. It is a key part of managing your sourcing and ensuring your suppliers consistently meet your quality expectations. This control is essential for regulatory compliance and protecting your bottom line.

Quality Control and Quality Assurance

You must ensure your products are fresh, consistent, and safe across all locations. Handling bulk orders should never mean sacrificing quality. A robust quality assurance system gives you the control to prevent defects before they happen. This system protects your brand, reduces waste, and ensures regulatory compliance. Your quality assurance framework should be built on three critical checkpoints.

Pre-Production Checks

Your quality control starts long before any food processing begins. This initial stage focuses on your sourcing and the verification of all incoming materials. A failure here can compromise your entire production run. In fact, many product recalls trace back to suppliers. One survey showed 61% of companies blame suppliers for up to half of their recalls. You must be diligent.

Your first step is to vet your suppliers. You need to confirm they adhere to recognized standards.

| Certification Body | Scope of Focus |

|---|---|

| BRCGS | Manages product safety, quality, and legality for food, packaging, and distribution. |

| SQF | A rigorous food safety and quality program covering all sectors from farm to retail. |

| FDA / USDA | Ensures regulatory compliance for the US food supply, including safety and labeling. |

You must also verify the quality of your packaging materials. Your suppliers should provide documentation for all packaging. Request a Certificate of Conformance to ensure the packaging meets your specifications. For an extra layer of quality assurance, ask for a Certificate of Analysis, which provides actual test results for a specific batch. This inspection is vital for compliance and safety. Your sourcing strategy must include these checks to maintain control over your supply chain.

In-Production Monitoring

Once production starts, you need to monitor processes in real time. This stage of quality assurance helps you catch deviations as they happen, not after you have a warehouse full of faulty products. Effective in-production monitoring is key to consistency and cost control.

Your team should perform a "first article inspection." You check the very first products off the line against your standards. This confirms that equipment, including any automatic plastic sealing machine, is calibrated correctly and that the food processing is running as planned.

Key In-Production Monitoring Activities 💡

- Process Control: You establish and follow Standard Operating Procedures (SOPs) to monitor every stage of food processing. This maintains consistency and detects risks early.

- Equipment Checks: You must ensure every

automatic plastic sealing machineprovides a perfect seal. A faultyautomatic plastic sealing machinecan ruin your packaging and compromise food safety.- Staff Training: Your team needs training on portion control and standardized recipes. This directly reduces food waste and high costs. For example, Pitfire Pizza saved $55,000 by using data to identify and correct over-portioning.

Continuous monitoring of your automatic plastic sealing machine and other equipment is essential for packaging integrity. This proactive quality control approach prevents small issues from becoming expensive problems. It is a core part of your logistics and compliance strategy.

Post-Production Final Inspection

The final inspection is your last chance to catch errors before products ship. This step validates the quality of the finished goods and the security of the packaging. It is a critical control point for your brand's reputation. Your quality assurance depends on a thorough final check.

You should conduct a series of tests on a random sample of the finished products.

- Sensory Evaluation: You judge the taste, smell, and appearance of the food.

- Microbiological Testing: You test for harmful microorganisms to ensure food safety.

- Packaging Inspection: You check that all packaging is intact. You confirm every

automatic plastic sealing machinehas created a durable, airtight seal. The quality of the packaging is as important as the quality of the food inside.

Finally, you must supervise the loading process. Proper logistics prevent damage and spoilage during transit.

Best Practices for Loading Perishables 🚚

- Pre-cool the truck to the required temperature before loading.

- Organize the shipment to allow for proper airflow.

- Minimize loading time to reduce exposure to ambient temperatures.

This final inspection ensures your sourcing efforts pay off. You verify that your suppliers have met their obligations, your automatic plastic sealing machine has performed correctly, and your packaging is secure. This rigorous compliance check protects your investment and delivers the quality your customers expect. Your automatic plastic sealing machine is a key tool, and its performance must be verified. The automatic plastic sealing machine ensures your packaging is perfect. A reliable automatic plastic sealing machine is crucial for all packaging operations. Your automatic plastic sealing machine is the final guardian of your product's freshness.

Using AQL for Objective Acceptance

Your quality control system needs an objective standard. Acceptance Quality Limit (AQL) gives you a statistical tool to decide whether to accept or reject a bulk order. This method, based on international standards like ISO 2859, allows you to assess quality without a 100% inspection. It provides a clear, data-driven basis for decisions with your suppliers.

Understanding AQL Basics

You use AQL to manage quality and risk in your sourcing. Instead of checking every single item, you perform an inspection on a predetermined sample size. AQL helps you define the maximum number of defective units allowed in that sample. If the inspection finds more defects than the limit, you can reject the entire batch. This process gives you leverage over your suppliers and protects your food quality.

How AQL Creates an Objective Standard 🎯

- Standardized Sampling: You use internationally recognized AQL tables to determine your sample size for inspection.

- Maximum Defects: You set a clear limit on the number of acceptable defects before the inspection begins.

- Defect Classification: You categorize issues to focus on what matters most for your food and packaging.

Defining Your AQL Standards

You must classify defects to apply AQL effectively. This helps you prioritize issues that impact safety and usability. Your suppliers need to understand these standards. You should define your quality expectations for both the food and its packaging. A faulty seal from an automatic plastic sealing machine, for instance, can be a major defect.

| Type of Defect | Definition | AQL Threshold | Example |

|---|---|---|---|

| Critical | A defect that is hazardous or unsafe. | 0% | Contaminants in food; a faulty automatic plastic sealing machine creating a non-hermetic seal on packaging. |

| Major | A defect that affects usability or appearance. | 2.5% | Incorrect weight; a weak seal from an automatic plastic sealing machine on the packaging. |

| Minor | A small issue that does not affect product use. | 4.0% | Slight color variation; a cosmetic flaw on the packaging. |

Your strategic sourcing should account for these standards. High-risk aspects, like packaging seal integrity from an automatic plastic sealing machine, require a stricter AQL.

AQL in a Real-World Scenario

Imagine you receive a shipment of 10,000 packaged meals from one of your suppliers. Your AQL inspection process begins.

- You use an AQL table to determine your sample size is 200 units.

- You define your AQL for defects: 0 for critical, 2.5 for major, and 4.0 for minor.

- Your team conducts the inspection on the 200 units of food.

During the inspection, you check the food quality and the packaging integrity. You verify the performance of the supplier's automatic plastic sealing machine. A reliable automatic plastic sealing machine ensures proper packaging. If the automatic plastic sealing machine failed, the packaging is compromised. Your inspection finds one major defect (a bad seal from an automatic plastic sealing machine) and seven minor defects. The performance of the automatic plastic sealing machine is key to your packaging quality. Since these numbers are within your AQL limits, you accept the shipment. This sourcing method ensures compliance and supports your regulatory compliance efforts. The automatic plastic sealing machine is a critical checkpoint for all packaging. Your suppliers must maintain their automatic plastic sealing machine to guarantee packaging quality.

This bulk order guide gives you an integrated framework. You manage cash flow with smart payments. You protect your food and packaging with robust quality control. You use AQL for objective acceptance. Mastering these areas gives you control over your suppliers and is crucial for reducing food costs. It improves your food quality and packaging quality.

Adopt this systematic approach. You can build a more resilient and profitable supply chain. Use data to move beyond outdated practices and ensure the highest quality for your food and packaging. This bulk order guide helps you gain control over your suppliers and your final product quality.

FAQ

How do I start implementing AQL with a new supplier?

You should communicate your AQL standards clearly in your contract. Define critical, major, and minor defects for your supplier. This practice ensures your supplier understands your quality expectations for both food and packaging before production begins. This sets a clear foundation for your partnership.

What is the most important check for packaging quality?

You must verify the seal integrity. A faulty automatic plastic sealing machine can cause leaks and spoilage. Your quality control process should always inspect the seals. A reliable automatic plastic sealing machine is essential for food safety and maintaining product freshness.

Can I use different payment terms for different suppliers?

Yes, you should tailor payment terms based on your relationship and order value.

- Use Net 30/60 for trusted, long-term partners.

- Consider a Letter of Credit for large, high-risk international orders. This flexibility helps you manage risk and cash flow effectively across your supply chain.

Why is an automatic plastic sealing machine so critical?

Your automatic plastic sealing machine creates the final barrier protecting your food. A perfect seal prevents contamination and extends shelf life. Consistent performance from this machine is vital for your brand's quality, customer safety, and overall regulatory compliance. It is a key piece of equipment.