Choosing Freight by Total Landed Cost

Food chains often face a choice for shipping acrylic displays: cheap sea freight or fast air freight. The decision depends on a metric called total landed cost. A low freight bill does not guarantee the lowest final expense. Supply chain disruptions cost the food industry over $1 trillion each year, making careful cost analysis critical.

The most profitable choice comes from calculating the complete total landed cost for each shipment. This guide helps businesses make that calculation.

What is Total Landed Cost?

Total landed cost represents the complete expense of transporting a product from a supplier to its final destination. This figure includes the initial product price plus all costs from origin to delivery. A business must look past the initial freight bill to understand its true financial commitment for a shipment.

Beyond the Freight Bill

An initial freight quote rarely shows the full picture. Many other expenses appear during the shipping process. These costs can make up a significant portion of a product's final price, sometimes as much as 40 percent. Businesses must account for these variable charges to avoid budget overruns.

Note: Unexpected fees often arise after a shipment is in transit. These can include fuel surcharges, port handling fees, documentation costs, and customs clearance charges. A clear understanding of these potential costs is essential for accurate budgeting.

Key Cost Components

Calculating the total landed cost involves adding several key expenses together. A comprehensive calculation provides a true measure of a shipment's financial impact. The primary components include:

- Product Price: The base cost paid to the supplier for the acrylic displays.

- Freight Costs: The charge for moving goods by air or sea.

- Customs and Duties: Government taxes and tariffs on imported items.

- Insurance: Premiums paid to protect goods against loss or damage.

- Handling and Operating Costs: Fees for loading, unloading, packaging, and inspections.

Why It Matters for Displays

Acrylic displays introduce unique challenges. The material is fragile and can scratch easily. It also becomes brittle and may crack in cold temperatures, a risk during unheated truck or air transit. These characteristics demand special handling and packaging, such as foam inserts and protective wrapping. These protective measures increase handling and operating expenses. Factoring these specific needs into the calculation is critical. It ensures the displays arrive safely and prevents unexpected costs from damaging the project's profitability.

Air vs. Sea: A Head-to-Head Comparison

Choosing between air and sea freight requires a detailed look at more than just the initial price. Each mode has distinct advantages and disadvantages that directly affect the Total Landed Cost of acrylic displays. A business must compare them across several key areas to find the most profitable option.

Freight Rates and Surcharges

Air freight has a significantly higher base rate than sea freight. The cost to ship by air is often calculated per kilogram and can be substantial for heavy goods. Sea freight offers a much lower cost per kilogram, especially for large, bulky shipments.

- Air Freight: Rates typically range from $3.50 to $8.00 per kilogram.

- Sea Freight: Costs can be as low as $0.10 to $0.30 per kilogram for full container loads.

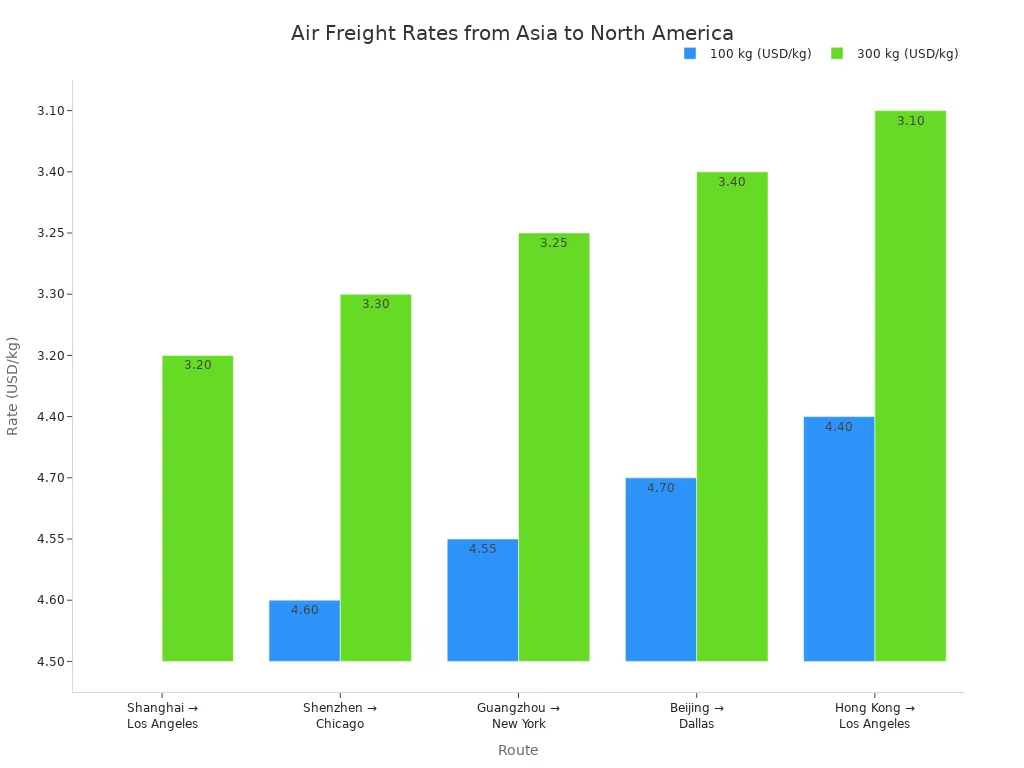

Rates also change based on shipment volume. Heavier shipments often receive a lower price per kilogram. The chart below shows sample air freight rates from major hubs in Asia to North America, illustrating how costs decrease as shipment weight increases.

However, the base freight rate is only part of the story. Both modes have surcharges that add to the final bill.

Carriers apply these fees to manage operational pressures and market changes. Common surcharges for sea freight include:

- Peak Season Surcharge (PSS): Applied during busy shipping seasons like major holidays.

- General Rate Increase (GRI): An adjustment to cover rising operational costs in the shipping industry.

- Low Sulphur Fee (LSF): A charge to cover the cost of cleaner, more expensive fuel.

- War Risk Surcharge (WRS): Applied on routes passing through regions with political instability.

Transit Time and Inventory

The most significant difference between air and sea freight is speed. This time difference has a direct impact on inventory costs and cash flow. Air freight delivers goods in days, while sea freight takes weeks.

| Service Type | Transit Time (China to USA) |

|---|---|

| Air Freight | 3-5 days |

| Sea Freight | 30-40 days |

Longer transit times for sea freight mean that a company's capital is tied up in in-transit inventory. These are products that have been paid for but cannot be sold. This inventory often accounts for 25% to 30% of a company’s working capital.

Financial Impact: Slow-moving inventory strains a company's cash flow. The capital locked in those goods cannot be used for other business needs, such as marketing, payroll, or new product development. Poor inventory management reduces a business's overall profitability.

Insurance and Risk

The journey itself presents different levels of risk. Air freight is generally safer. Goods experience less handling and spend less time in transit, which lowers the risk of damage. Statistics show that damaged goods account for a significant portion of aviation claims, but the overall risk is lower compared to ocean transit.

In contrast, sea freight carries a higher risk of damage and loss. The extended transit time exposes cargo to rough seas and temperature changes. Containers also go through more handling at ports. While rare, total loss is a possibility. On average, 546 containers fall into the sea each year. This increased risk for sea freight often results in higher insurance premiums, adding to the Total Landed Cost.

Customs, Duties, and Fees

Customs and port fees are another critical cost component. Air freight shipments often move through customs faster, but the associated brokerage fees can be high. These charges are sometimes considered a hidden cost of air shipping.

Sea freight appears cheaper upfront but comes with its own set of destination charges. These fees can add up quickly.

- Destination Terminal Handling Charges (DTHC): These fees cover the cost of moving a container from the ship to the port stack and onto a truck. For a 20ft container from Asia to the US, the average DTHC is around $550.

- Port Congestion Surcharges (PCS): When a port is busy, carriers add this fee, which can be several hundred dollars per container.

- Demurrage and Detention Fees: These are penalties for not picking up a container or returning it on time.

Packaging and Handling

Acrylic displays require careful packaging, and the shipping method dictates the type of protection needed. The longer, rougher journey of sea freight demands more robust and expensive packaging.

For sea shipments, wooden crates must have an ISPM 15 certification, or "bug stamp." This stamp proves the wood has been treated to prevent pests. Without it, customs can reject the entire shipment, causing major delays and costs. Crates must be strong, with foam inserts and reinforced edges to protect the displays.

| Shipment Type | Packaging Materials Recommended | Implied Cost Impact (Material & Labor) |

|---|---|---|

| Air | Reinforced cartons, flat-pack designs | Lower material and labor costs |

| Sea | ISPM 15 certified crates, foam inserts, desiccant bags | Higher material and labor costs |

Calculating Your Total Landed Cost

A business can move from guessing to knowing by calculating the costs for each shipping method. This process breaks down the total landed cost into manageable steps. It provides a clear financial comparison between air and sea freight options.

A Simple TLC Formula

The calculation starts with a basic formula. This formula helps organize all the different expenses into one final number. A business can use this simple equation to find its true cost.

Total Landed Cost = Product Cost + Shipping + Customs + Risk + Overhead

Step 1: Gather Cost Data

First, a company must collect all necessary financial data. It needs quotes for the acrylic displays from the supplier. It also needs freight quotes for both air and sea transport. Finally, it should get estimates for customs duties, insurance premiums, and any handling fees.

Step 2: Model the Air Freight Cost

Next, the business applies the collected data to the air freight option. It adds the product price, the air freight quote, and all associated fees. This includes higher insurance or special handling costs for air transit. The result is the total cost for shipping the displays by air.

Step 3: Model the Sea Freight Cost

The company then repeats the process for sea freight. It uses the same formula but substitutes the sea freight costs. This calculation must include expenses like robust crating, port fees, and higher insurance premiums associated with the longer, riskier sea journey.

Step 4: Compare and Decide

The final step is to compare the two models. The option with the lower cost is often the logical choice. However, a smart decision looks beyond just the numbers. A business must also weigh non-financial risks that can affect a shipment.

- Supplier Reliability: A supplier with a history of poor performance or labor issues presents a risk, even if their price is low.

- Political Disruption: Events in a supplier's region can stop production or shipping without warning.

- Innovation: A supplier's ability to innovate and improve product quality is a valuable long-term asset.

Considering these factors alongside the final cost figures helps a business make the most secure and profitable decision.

Making the Right Choice: Scenarios

Calculating the Total Landed Cost provides the numbers. The next step involves applying those numbers to real-world business situations. The best freight choice depends entirely on the specific needs of each shipment. A company must weigh cost against urgency, risk, and opportunity.

When to Use Air Freight

Air freight is the solution for speed. Its higher cost is justified when time is more valuable than the savings from sea shipping. Businesses should consider air freight in several key scenarios.

An urgent grand opening is a classic example. A restaurant chain cannot open a new location without its branded acrylic displays. Delays mean lost revenue and a poor first impression. Air freight ensures the displays arrive on time for the launch. Similarly, if a display arrives damaged, air freight can deliver a replacement quickly. This speed minimizes disruption to store operations.

Pro Tip: A good rule of thumb is to consider air freight when the total shipping cost is less than 15-20% of the product's value. For high-value, custom-made displays, the extra freight cost is a small price for ensuring a safe and timely arrival.

The value of the shipment also plays a role. Air freight is often the better choice for smaller, high-value items. The shorter transit time and reduced handling lower the risk of damage or loss. This speed can also protect profits. For example, a 2,000 kg shipment might cost $6,000 by air but only $1,400 by sea. If a stockout from a 25-day sea transit would cause $7,500 in lost sales, the higher air freight cost becomes a smart investment.

Real-world situations show the power of air freight for urgent needs.

| Client / Company | Event | Shipment Solution |

|---|---|---|

| Technology Client | Investor demo in Frankfurt | Shipped two fragile prototypes in shock-mounted crates. The items arrived in 48 hours, helping the client secure funding. |

| Pharmaceutical Company | Product launch in the UK | Shipped over 400 pallets of materials from China. A rapid air solution met a strict deadline for the launch. |

Finally, market conditions can make air freight necessary. It is ideal for products with short life cycles, like seasonal promotional displays. During peak seasons, air freight allows for quick inventory replenishment to meet high demand.

When to Use Sea Freight

Sea freight is the champion of cost-efficiency. It is the default choice for businesses that can plan ahead and prioritize the lowest cost per unit. This method works best for large, heavy, and non-urgent shipments.

A chain-wide rollout is a perfect scenario for sea freight. A company ordering hundreds of acrylic displays for all its locations can save a significant amount of money. Sea freight costs can be as low as $0.10 per kilogram, while air freight can cost $5.00 or more per kilogram. For a large order, these savings add up to thousands of dollars. This makes sea freight ideal for stocking a central warehouse with standard inventory.

The key to using sea freight successfully is managing its long lead times. A transit time of 30-40 days requires careful planning. Businesses can use several inventory management techniques to prevent stockouts.

- Classify Inventory: Companies should identify their most critical items. They can focus their planning efforts on these products to ensure they are always in stock.

- Improve Communication: Regular talks with suppliers help manage expectations. Sharing sales forecasts allows suppliers to prepare for future orders.

- Optimize Order Frequency: Placing smaller, more frequent orders can reduce risk. This strategy avoids tying up too much capital in a single large shipment.

- Plan for Disruptions: Businesses must prepare for events like the Lunar New Year, which shuts down factories. Ordering extra inventory well in advance prevents supply gaps.

Sea freight is suitable for products with a long shelf life. A clothing company, for instance, can ship its spring collection in November. The ample lead time makes the cost-effective sea journey the logical choice. This long-term planning is the foundation of a cost-effective supply chain.

Sea freight often appears cheaper, but air freight can offer a lower total landed cost in time-sensitive situations. The best choice is unique to each shipment's circumstances. Businesses must calculate all expenses to protect profit margins and guide financial decisions. This analysis ensures supply chain costs are controlled. A company should stop guessing and start calculating to ensure its acrylic displays arrive on time and profitability is maximized.

FAQ

### What is the most important part of Total Landed Cost?

The most important part is the final, all-inclusive number. A business must look beyond the freight bill. It should add every expense, from product cost to customs fees. This complete view reveals the true cost of a shipment and prevents surprise expenses.

### Is sea freight always cheaper than air freight?

No, sea freight is not always the cheapest option. 🚢 While its base rate is lower, its Total Landed Cost can be higher. Factors like long transit times, higher insurance, and robust packaging needs add to the final expense, sometimes making air freight more economical.

### Why does packaging matter so much for acrylic displays?

Packaging is critical for protecting fragile acrylic. Sea freight requires strong, certified wooden crates to survive the long journey. 📦 Air freight allows for lighter, less expensive packaging. The right choice protects the product and controls handling costs within the TLC calculation.

### How does transit time affect cost?

Longer transit times tie up a company's money in inventory. Products on a ship cannot be sold. This strains cash flow. ✈️ Air freight delivers goods quickly, freeing up capital. A business must weigh the freight savings against the cost of holding unsold inventory.