Acrylic vs. Plexiglass: What’s the Difference? (And Why It Matters for Premium Acrylic Products in 2024)

Introduction: Acrylic and Plexiglass—More Than Just Names

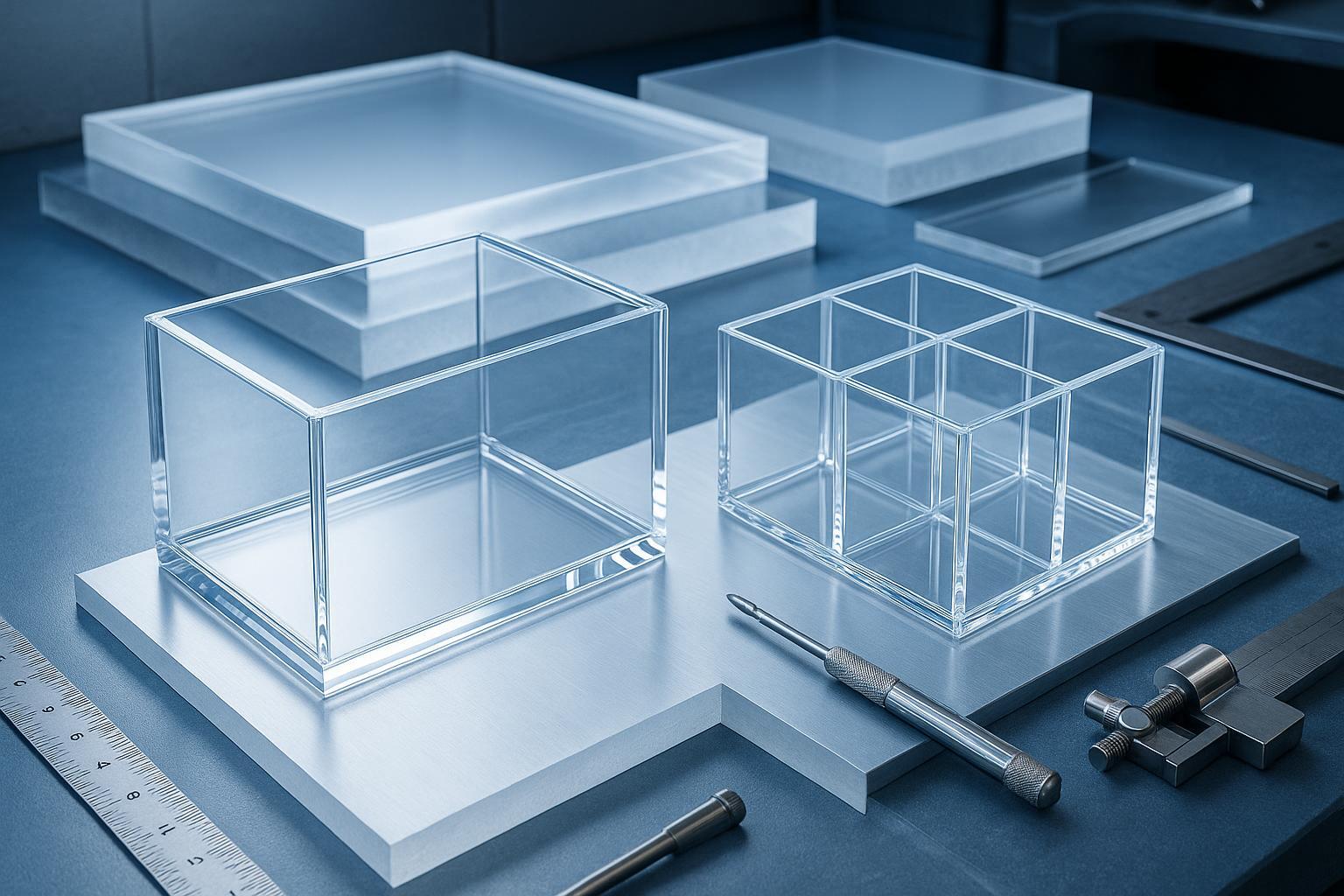

If you’ve ever searched for display cases, protective covers, or stylish organizers, you’ve probably run into the terms acrylic and plexiglass—sometimes used as if they’re the same, sometimes as if they’re totally different. So, which is it? Are they just two words for the same thing, or is there more beneath the surface? Understanding this distinction isn’t just for science buffs—it’s essential for brands, designers, and anyone who wants premium clarity and durability in their products.

Unpacking the Basics: Defining Acrylic and Plexiglass

Let’s start with the essentials:

Acrylic refers to a broad family of clear, flexible plastics made from a substance known as polymethyl methacrylate (PMMA). It’s renowned for its excellent clarity, weather resistance, and ability to be molded or shaped into countless forms.

Plexiglass was originally a brand name (Plexiglas®) invented in Germany in the 1930s, used for a specific type of PMMA sheet. Over time, it became so successful that "plexiglass" turned into a catch-all term for all acrylic sheets—similar to how people say "Kleenex" for facial tissues or "Xerox" for photocopies, even if it’s not the original brand (Source).

In other words: All plexiglass is acrylic, but not all acrylic is technically "Plexiglas®." Today, however, they're used nearly interchangeably, especially in the US.

Getting Technical: PMMA, Brands, and Manufacturing Realities

Acrylic’s base ingredient, PMMA, is the true technical name. Whether you call it acrylic, plexiglass, Lucite® (US brand), or Perspex® (UK brand), you’re almost always talking about products made from PMMA (RTPrototype). So, why do differences matter?

Quality can vary based on manufacturing (cast vs. extruded), additives, and brand reputation.

Industrial buyers may use brand names to specify requirements for certifications, performance, or country of origin.

For end buyers and designers, the important factor is understanding how the acrylic sheet was made and what properties it brings to your project.

Cast vs. Extruded Acrylic: The Heart of Product Performance

When buying or specifying acrylic (or plexiglass) products, the manufacturing method really matters:

Aspect | Cast Acrylic | Extruded Acrylic |

|---|---|---|

Optical Clarity | Superior (premium displays, optics) | Very good, slightly less sharp |

Surface Hardness | Higher, more scratch-resistant | Slightly softer |

Machinability | Ideal for laser cutting, complex shapes | May burr when machined, best for simple cuts |

Strength | Tough, dense, less internal stress | Slightly more flexible, lower impact resistance |

Price | Higher—premium look and performance | More affordable—great for standard applications |

For high-end applications like luxury display boxes, watch stands, or artistic trophies, cast acrylic is often the gold standard (American Acrylics). Extruded acrylic is perfectly serviceable for signage, basic organizers, and budget-conscious bulk uses.

How Does This All Play Out in Real-World Products?

Let’s bring this down to earth with practical examples from the world of custom acrylic manufacturing:

Display & Presentation: Clarity is King

When a retail brand or luxury collector needs a striking display box with absolute visual clarity, high-grade cast acrylic offers the "museum glass" look—no yellowing, waves, or cloudy spots. That’s why companies like TOYIN use top-tier acrylic sheets and strict ISO9001 quality processes to ensure flawless finishes for their clients’ display solutions.

Organizers & Furniture: Durability, Safety, and Flexibility

Acrylic desk organizers and furniture pieces require both beauty and strength. High-quality acrylic outperforms budget “plexiglass” in resisting scratches, staying crystal clear, and supporting custom fabrication (like laser-engraved edges or LED integration). TOYIN’s advanced production—using both precision cutting and thermoforming—brings these design possibilities to life for offices, shops, and home users around the world.

Trophies & Signage: Customization Matters

For awards or signage that need eye-catching colors, sharp graphics, or intricate shapes, acrylic’s versatility is unmatched. Specialty grades (UV-resistant, anti-static, or extra-thick) can be sourced for truly unique outcomes, a process that custom manufacturers like TOYIN excel at.

Beyond Acrylic and Plexiglass: How Do They Stack Up?

You might wonder—if acrylic is so amazing, why not just use glass, polycarbonate, or PETG? Here’s a quick comparison:

Property | Acrylic/Plexiglass | Glass | Polycarbonate | PETG |

|---|---|---|---|---|

Clarity | Excellent | Excellent | Very good (thicker) | Good |

Weight | Light | Heavy | Light | Light |

Impact Resistance | High (17x glass) | Moderate | Highest | Good |

Scratch Resistance | Good | Very good | Lower | Moderate |

Custom Shaping | Easy | Difficult | Easy | Easy |

Cost | Moderate | High | Higher | Moderate |

For applications where clarity, weight, and custom fabrication matter most, acrylic outshines the competition (Eagle Plastics).

2024 Trends: Sustainability, Certifications, and the Modern Buyer

New market demands mean buyers are looking for eco-friendly, certified, and high-performance acrylic solutions:

Sustainability: Recycled and bio-based acrylics are on the rise (Allied Market Research). Companies like TOYIN incorporate eco-conscious sourcing and manufacturing to support global standards.

Certifications: Look for ISO 9001 quality control, UL 94 safety/flame ratings, and compliance with regional standards. Manufacturers should be transparent about their material sources and processes (Plaskolite).

Customization and Responsiveness: In today’s competitive landscape, rapid quoting, global delivery, and the ability to deliver custom, precision-engineered solutions (all part of TOYIN’s core offering) are huge value factors for brands and designers.

Making an Informed Choice: Practical Selection Tips

Here’s what to consider when choosing the right material for your application:

Intended Use: Is clarity, impact resistance, or budget your top concern?

Appearance: Will your audience notice and appreciate the difference between economy-grade (extruded) and premium (cast) acrylic?

Machinability: Will the product require tight tolerances, engraving, or multi-part assembly?

Certifications: Do you need fire, safety, or environmental certifications for your target market?

Eco-Friendliness: Does the supplier offer sustainable or recycled options?

For premium, eye-catching, and durable results—especially where product presentation, brand image, and global compliance are key—partnering with an expert custom manufacturer like TOYIN delivers peace of mind and market-leading quality.

Conclusion: Acrylic or Plexiglass—Choose Knowledge, Not Just a Name

In the world of clear plastics, it’s not the terminology that matters, but the properties, manufacturing quality, and service behind your product. Whether you call it acrylic or plexiglass, understanding the differences (and what truly goes into your custom display, organizer, or furniture) helps you select the very best for your business or brand.

Ready to elevate your project with premium acrylic products? Explore TOYIN’s full range of custom solutions or request a quick, expert quote today.