Acrylic vs Glass vs PETG A Retail Guide

You need the perfect display for your high-value electronics. This choice directly impacts product presentation, safety, and your budget. The decision of Acrylic vs glass vs PETG is a critical one for any retailer.

Note: The market for materials like PETG is growing fast. It is projected to reach USD 3.82 billion by 2033. This shows how important these materials are in modern retail.

Your final selection depends on your store's unique priorities. Understanding the strengths of each material helps you make the best investment for your brand and products.

Acrylic vs Glass vs PETG: A Direct Comparison

Choosing the right material requires a direct look at how each performs. Your decision in the Acrylic vs glass vs PETG debate will shape your store's look, safety, and budget. Let's break down the key differences.

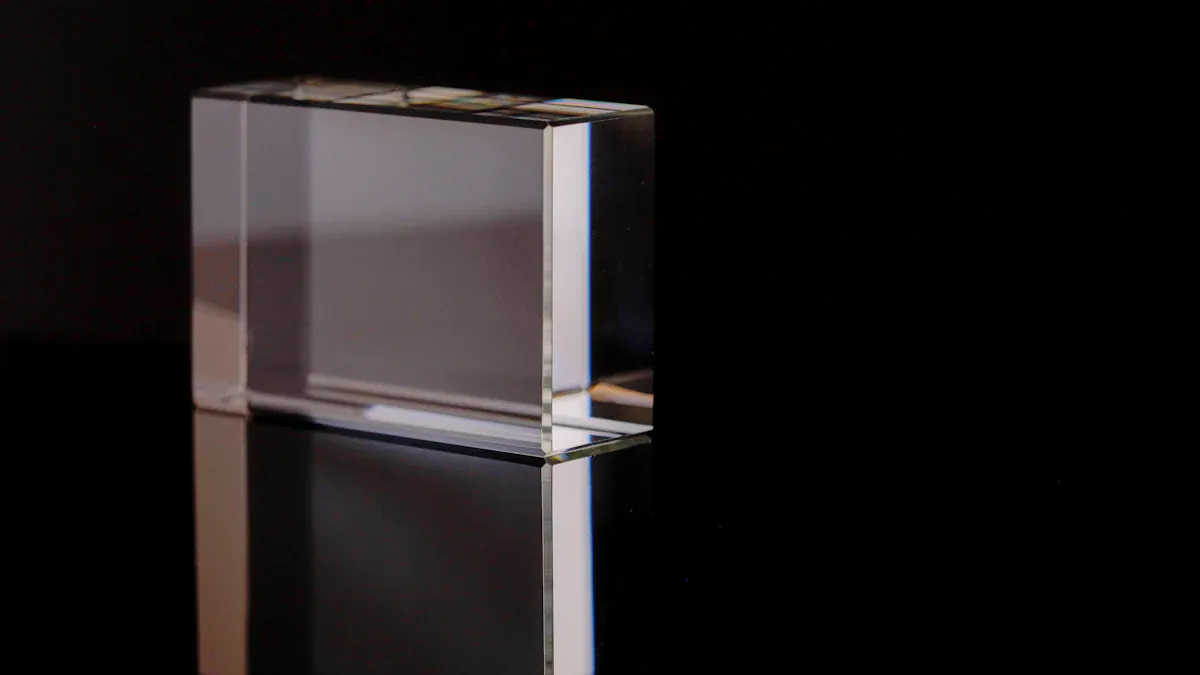

Clarity and Aesthetics

How your products look to customers is paramount. The material you choose is the literal lens through which they see your merchandise.

Acrylic: You get exceptional optical clarity with acrylic. It often transmits more light than standard glass, making products appear brighter and more vibrant. It provides a rigid, high-end, glass-like appearance without the risk of a green tint. Over time, acrylic shows excellent UV resistance, meaning it will not turn yellow from sun or store lighting exposure.

Glass: You can't deny the premium feel of real glass. It communicates luxury and quality. However, standard glass often has a slight green tint, which can subtly alter the color of the products behind it.

PETG: This material offers good clarity and is a solid choice. It may not look quite as "crisp" or rigid as acrylic, but it presents products clearly and effectively.

Pro Tip: For displaying items where color accuracy is critical, like smartphone screens or colorful accessories, acrylic's superior optical clarity gives it an edge.

Durability and Impact Resistance

Retail environments are high-traffic areas. Accidental bumps and knocks are inevitable, making impact resistance a crucial factor.

PETG is the clear winner in this category. It is virtually shatterproof and can withstand significant impacts without breaking, making it ideal for displays in busy aisles or at lower heights. Acrylic is much stronger than glass, offering about 17 times the impact resistance. It might crack under extreme force but won't shatter into dangerous shards. Tempered glass is strong, but when it fails, it shatters completely into many small, granular pieces. This can create a safety hazard and a cleanup challenge. The choice between Acrylic vs glass vs PETG often comes down to this single safety factor.

Scratch Resistance

While durability protects against breaks, scratch resistance preserves the pristine look of your displays. Here, the materials show a clear trade-off.

Glass is the most scratch-resistant of the three. Its hard surface stands up well to daily cleaning and casual contact. Acrylic offers good scratch resistance, certainly better than PETG. PETG is the softest of the three materials, making it more prone to surface scratches.

You can see this difference in scientific hardness ratings.

Material | Rockwell Hardness | |

|---|---|---|

Glass | 5.5 – 7 | N/A |

Acrylic | 3 – 4 | |

PETG | ~2.5 |

Note: While PETG has a higher Rockwell "R" score, it is on a different scale than acrylic's "M" score. The Mohs scale provides a more direct comparison, showing glass is the hardest, followed by acrylic.

Cost and Budget

Your budget will heavily influence your material choice. The costs vary not just for the material itself but also for shipping and installation.

Acrylic: Generally, this is your most cost-effective option. A standard 1/4" sheet of clear cast acrylic can start from around $6.24 per square foot.

PETG: This material typically sits in the middle of the price range, costing more than acrylic but less than tempered glass.

Glass: Tempered glass is the premium choice and carries the highest price tag for both the material and the associated shipping, which is higher due to its weight.

The ongoing debate of Acrylic vs glass vs PETG must always consider these financial realities. Acrylic provides a high-end look without the high-end price, offering an excellent return on investment for most retail applications.

Fabrication and Design

Do you need simple protective cases or complex, branded fixtures? Your design ambitions will point you toward the right material.

Both acrylic and PETG are thermoplastics, making them easy to work with. Glass, on the other hand, is very difficult to customize.

Acrylic: This is a fabricator's favorite. It can be laser-cut with extreme precision, leaving a flame-polished edge that requires no extra finishing. This makes it perfect for intricate logos and complex shapes.

PETG: Also easy to fabricate, PETG is excellent for simpler shapes and is especially good for heat bending, as it retains its strength well after being formed.

Glass: Customizing glass is an expensive and complex process. Cutting custom shapes or drilling holes requires specialized equipment and adds significant cost.

This table highlights some key fabrication differences:

Feature/Technique | Acrylic | PETG |

|---|---|---|

Laser Cut Edge | Exceptionally clean, polished edge | Clean edge, but may discolor |

Heat Bending | Good, but can become weak at bend | Excellent, retains strength |

Design Complexity | Ideal for intricate, polished designs | Best for durable, simpler shapes |

Because acrylic is about 50% lighter than glass, you also save on shipping and installation costs. It requires less robust support structures, giving you more design freedom.

Best Use Cases in a Retail Setting

Understanding the unique strengths of each material helps you decide where to use them in your store. Your choice in the Acrylic vs glass vs PETG matchup should align with your brand, budget, and safety needs for specific locations.

When to Choose Acrylic: The All-Rounder

You should choose acrylic when you need a versatile material that balances aesthetics, cost, and durability. It is the perfect all-rounder for most retail environments. Its combination of features makes it an excellent long-term investment.

Use acrylic for:

Countertop Displays: Its light weight makes it ideal for risers, sign holders, and cases that sit on your counters. Acrylic is about half the weight of glass, so you can move and adjust these displays easily without needing heavy-duty support.

Wall-Mounted Shelving: You can create stunning "floating" shelves for accessories or smartphones. The material's strength and light weight reduce installation complexity and cost.

Branded Fixtures: Acrylic is perfect for creating displays with intricate, laser-cut logos. The edges come out clean and polished, giving your brand a sharp, professional look.

Product Protection: You can protect valuable merchandise from fading. Standard acrylic blocks approximately 98% of harmful UV rays. This feature preserves the color and integrity of your products, even under bright store lights or near windows.

Pro Tip: A well-maintained indoor acrylic display can have a long life. With proper care and secure installation, you can expect your displays to last from 5 to 10 years, making them a smart financial choice.

When to Choose Glass: The Premium Option

You should choose glass when your brand identity is built on luxury and you want to create an unmatched premium experience. The weight and feel of glass communicate quality and exclusivity to your customers.

Use glass for:

High-End Jewelry and Watch Cases: Luxury brands often use glass to create a sense of prestige. For example, brands like Cartier use high-gloss finishes and Tiffany & Co. uses its iconic blue to reinforce brand identity within their glass displays.

Flagship Store Fixtures: For your most important locations, glass makes a powerful statement. Minimalist designs that elevate a single product on a pedestal inside a glass case create an aura of high value.

Displays for Color-Critical Electronics: If you need perfect color accuracy, you should invest in low-iron glass. This type of glass eliminates the green tint found in standard glass and transmits more light (around 91-92%). Your products will look brighter, and their colors will appear true and vibrant.

Note: While glass is the most expensive option, it is essential for brands that want to attract discerning customers. These premium displays are crucial for showcasing product exclusivity and can lead to higher customer engagement.

When to Choose PETG: The Safety-First Champion

You should choose PETG when impact resistance and safety are your absolute top priorities. Its virtually shatterproof nature makes it the champion of durability in high-traffic retail spaces.

Use PETG for:

Low-Level Bins and Shelving: Place PETG displays in areas where bumps from shopping carts, strollers, or children are likely. You will not have to worry about dangerous shattering.

Protective Barriers and Sneeze Guards: Its high impact strength and good clarity make it an excellent material for safety shields at checkout counters.

High-Traffic Aisle Displays: For freestanding displays in busy aisles, PETG provides peace of mind. It can withstand significant force without cracking or breaking.

When cleaning PETG, you have many options. It shows good chemical resistance to common cleaners like diluted acetic acid and alcohols. However, you must avoid harsh chemicals.

Chemical to Avoid | Potential Effect on PETG |

|---|---|

Unstable, will cause damage | |

Strong Acids | Unstable, will attack the surface |

Ammonia (High Concentration) | Can become unstable at higher temps |

Always test a cleaner on a small, hidden area first to ensure it does not damage the material. This simple step keeps your safety-first displays looking great.

Maintenance and Long-Term Value

Your displays are a long-term investment. Understanding how to care for them ensures they continue to look great and provide value for years to come. Proper maintenance protects your budget and your brand image.

Daily Cleaning and Care

Keeping your displays pristine is simple with the right technique. You want to clean the surface without causing damage.

Follow these steps for a safe and effective clean:

Turn off any electronic components in the display.

Use a dry, medium-grade microfiber cloth to gently wipe away dust.

For fingerprints or smudges, lightly spray a separate, fine microfiber cloth with distilled water or an alcohol-free cleaner. Never spray directly onto the display surface.

Wipe the smudged area in small, circular motions.

Let the surface air-dry completely before turning any electronics back on.

Pro Tip: You should always avoid using paper towels or harsh chemicals like alcohol-based cleaners. These can scratch the surface of acrylic and PETG or damage special coatings on glass.

Repairing and Polishing

Accidents happen, but some materials are more forgiving than others. Your ability to repair scratches varies significantly.

You can often repair minor scratches on acrylic yourself. The process involves wet sanding with progressively finer grits of sandpaper (from 600 to 1200) and then using an acrylic polish to restore the shine. For deep damage, you may need professional help. PETG is more difficult to repair. You can use a heat gun on a low setting to smooth minor surface scuffs, but this requires great care to avoid melting the material. Scratches on glass are generally permanent and cannot be polished out.

Environmental Considerations

The long-term impact of your material choice is an important factor. Each material has a different end-of-life story.

Glass is the most sustainable option, as it is widely and infinitely recyclable. Acrylic and PETG present more of a challenge. Both are thermoplastics with the resin code #7 ("Other"). While technically recyclable, facilities that process them are not common. PETG, in particular, is often sent to a landfill because it requires very high temperatures to be reprocessed. Your local recycling capabilities will determine the true environmental footprint of your displays.

Your final choice in the Acrylic vs glass vs PETG debate depends on your top priority. You must weigh the unique benefits of each material.

Acrylic offers a great balance of looks, cost, and customization.

Glass provides a premium feel with superior scratch resistance.

PETG delivers unmatched impact safety for busy areas.

For most stores, acrylic is the clear winner. It blends great looks with good durability and a friendly budget. You should consider glass if your brand is built on luxury. You should choose PETG if shatter-proofing is your main concern.

FAQ

Which material is best for food displays?

You should choose PETG for direct food contact, as it is often FDA-compliant. Acrylic can also be a good choice if it has a food-safe rating. You must always check the material's specifications to ensure it meets health and safety standards for your use case.

Can I use these materials for outdoor displays?

You can use acrylic for outdoor signs. It has excellent UV resistance and weathers well. PETG is also a solid option for outdoor use. You should avoid using standard glass outdoors, as it is not designed to handle weather and temperature changes without special treatment.

Which material is the easiest to install myself?

You will find acrylic is the easiest material for DIY installation. It is lightweight and rigid, making it simple to handle and mount. PETG is also light, but glass is very heavy and fragile. You should always hire a professional to install glass displays.

Remember: Safety first! Always wear protective gear like gloves and safety glasses when handling and installing any display materials.

Which material offers the best long-term value?

Acrylic offers excellent long-term value for most retailers. It provides a premium look at a budget-friendly price. Its durability, light weight, and resistance to yellowing ensure your displays look great for years, giving you the best return on your investment.